peterr said:

Does this mean you no longer use your airbearing arm?

Yes, Peter, I replaced it with an MG-1 (a commercial unit that looks like an Air Tangent clone).

My DIY arm had two problems (besides the noise, which I could live with). First, the horizontal effective mass was too high. My design was an ET2 clone (of sorts) and I never found a hollow shaft. The best I could find was an aluminum one that was still quite heavy. The other problem I never really figured out. There was a pair of forces that acted to push the arm to either the beginning or end of the record (away from the center of the playing area). The best theory was that there was some sort of venturi effect going on due to the high pressure. It did seem to be less of a problem when I reduced the pressure.

So, I've given up on it, at least for now. I've thought that I might try a Ladegaard or a Schroeder clone at some point, but for now the MG-1 is plenty good for me.

Paul,the horizontal effective mass was too high

Why don't you turn your setup upside down: stationare shaft and moving bearing with tonearm on it, (yes, Kuzma did it)? Methink it is the only way to address exceedingly large lateral mass. And I'm eager to try it some day, providing Bernhard send me his superflex tubes surplus (still waiting 🙁 ).

As for compressed air source: did you consider rechargeable air/nitrogen bottle (sort of pneumatic battery) with pressure regulator - shall be dead quiet and affordable.

Up to now, I personally do not feel my Ladegaard/Ortofon SPU Royal Navy combo (stiff suspention - good match to massive arm)may be beat by any arm by substantial margin. The only problem I still have is to address is lowest/nearly subsonic fq resonance peaks I hear playing some (not all) records. I'm still not complely sure about the root cause: is it the arm or maybe platter/base natural fq signature.

Forget it. It appeared after calculations, the standard scuba tank of 77 liter/3000 psi will last about 12 hours for the smallest of Newway bearing (1/4"). So, if you are not a scuba diver, i do not think it worth a mess with regular recharging.did you consider rechargeable air/nitrogen bottle (sort of pneumatic battery) with pressure regulator - shall be dead quiet and affordable.

Pity. Looked appealing.

newway bearing

i think the newway bearing stated something like 40psi of air input.

is it even remotely possible to use an aquarium pump supplying a much lower figure if i'm not going to support a few hundred pounds?

i think the newway bearing stated something like 40psi of air input.

is it even remotely possible to use an aquarium pump supplying a much lower figure if i'm not going to support a few hundred pounds?

Even if you will make the slider airborne (very questionable), you're compromizing severily the bearing stiffnes, loosing its main advantage vs. Ladegaard (which is rather good already and order of magnitude simplier/cheaper). Too bad.to use an aquarium pump supplying a much lower figure

livemusic said:

... providing Bernhard send me his superflex tubes surplus (still waiting 🙁 ).

And i am wondering if you received my tubing sample. Peterr received his weeks ago and i mailed them the same day.

Re: newway bearing

Based on my experience, I wouldn't use it with less than 20 psi, and 30 is really just adequate. It sounded terrific, btw, with 60 psi, but at that setting the forces pushing the arm away from center were quite high - I could basically only use it in the center of the record at 60.

Even at 60 psi, it was totally silent! Of course, the compressor wasn't...

garbage said:i think the newway bearing stated something like 40psi of air input.

is it even remotely possible to use an aquarium pump supplying a much lower figure if i'm not going to support a few hundred pounds?

Based on my experience, I wouldn't use it with less than 20 psi, and 30 is really just adequate. It sounded terrific, btw, with 60 psi, but at that setting the forces pushing the arm away from center were quite high - I could basically only use it in the center of the record at 60.

Even at 60 psi, it was totally silent! Of course, the compressor wasn't...

compressor

guess there is no way to use it at a low psi setting with a low noise pump... otherwise, this would be perfect to build an air bearing linear tracking tonearm with.

Paul Ebert said:

Based on my experience, I wouldn't use it with less than 20 psi, and 30 is really just adequate. It sounded terrific, btw, with 60 psi, but at that setting the forces pushing the arm away from center were quite high - I could basically only use it in the center of the record at 60.

Even at 60 psi, it was totally silent! Of course, the compressor wasn't...

guess there is no way to use it at a low psi setting with a low noise pump... otherwise, this would be perfect to build an air bearing linear tracking tonearm with.

Paul,Even at 60 psi, it was totally silent! Of course, the compressor wasn't...

did you ever try it with an airbrush compressor? Because this is what Kuzma uses.

Do you have an idea how much airflow it would need to stay afloat?

ps. does anyone know how to calculate airflow for a given presure and airgap (and whatever else you need to know) ? I have been looking around for a formula to calculate this but haven't been lucky till now

While we're asking questions . . . .

Would I get more PSI if I added a second aquarium pump feeding my surge tank? Or would the pressure just be limited by whichever pump created the least pressure?

-j

Would I get more PSI if I added a second aquarium pump feeding my surge tank? Or would the pressure just be limited by whichever pump created the least pressure?

-j

Konnichiwa,

If you connect the pumps in parallel you are limited by how much pressure the weaker one generates, but if you where to feed a pump with air that is already at a higher pressure than that the surrounding air, in other words connect the pumps in series.....

Sayonara

J Epstein said:Would I get more PSI if I added a second aquarium pump feeding my surge tank? Or would the pressure just be limited by whichever pump created the least pressure?

If you connect the pumps in parallel you are limited by how much pressure the weaker one generates, but if you where to feed a pump with air that is already at a higher pressure than that the surrounding air, in other words connect the pumps in series.....

Sayonara

J Epstein said:While we're asking questions . . . .

Would I get more PSI if I added a second aquarium pump feeding my surge tank? Or would the pressure just be limited by whichever pump created the least pressure?

-j

I think the extra pump would act as if it was in parallel - increase the airflow, but not the pressure. You'd have to figure out how to do the equivalent of putting them in series.

Maybe it could be done this way: start with two pumps (A and B) and a box. Route the output of pump A into the box. Enclose pump B inside of the box (except for the power cord, of course). Have the output of pump B exit the box and supply the pressure to the tank. The box, of course, needs to be airtight.

If you wanted to double the pressure, that might be worth trying. But I don't think I'd bother as an approach to get 20 or more psi. I think an airbrush or dental compressor would be better. But those aren't exactly cheap, though you could find an airbrush compressor used.

What we need is a pneumatics engineer. There must be a way to convert high airflow/low pressure into high pressure/low airflow. Such a person could probably solve my problem of the side forces as well.

Paul

OK, I'm just plain mechanical engineer, but I'll try to help here.we need is a pneumatics engineer

Paul, there is nothing complicated about your side force origin.

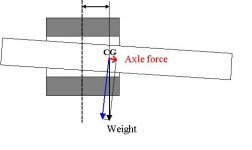

From the picture below, you'll see the slider is looking for equilibrum at some angle relatively to the bearing axle, while moving away from the bearig center, just beacause of the distance between its center of gravity (CG) and center of pressure applied by the bearing. So, projecting the slider weight vector on its axle, you have the side componet of the slider weight, which is driving crazy your arm. This is unstable system: the further slider moves away from the bearing center, the more side force is. Of cource, the angular deviation is rather small, but because you slider is so heavy, the side force becomes substantial enough, to bother you.

From my experience, air tracking arm reacts histerically on any side force, and shall be perfectly levelled and balanced.

That's why I'm saying the only way to build good high pressure/stiffness air arm is to make lightweight symmetrical slider/bearing/arm assembly and leave heavy shaft fixed firmly on its place.

As for air pump performance, typical pressure vs. flow chart shows, the more airflow you need, the less pressue you get. Any air pump is designed for specific pressure/flow characteristics. Looking through those currently proposed on ebay, I got an impression, the good air brush compressor performance suits well air tracker needs, providing typically 30-60 psi pressure and sufficient air flow. I now nothing about how loud are they, but some claimed to be very silent...

Attachments

silent aire compressors

according to this stereophile review, kuzma uses the sil air technology compressors.

a google on the web revealed that Silent Aire produces these compressors.

they have a supersilent model... comparisons of noise levels shown below:

according to this stereophile review, kuzma uses the sil air technology compressors.

a google on the web revealed that Silent Aire produces these compressors.

they have a supersilent model... comparisons of noise levels shown below:

Silent Air compressor

There is one currently on eBay:

http://cgi.ebay.com/Air-Brush-Compr...220642345QQcategoryZ28111QQrdZ1QQcmdZViewItem

There is one currently on eBay:

http://cgi.ebay.com/Air-Brush-Compr...220642345QQcategoryZ28111QQrdZ1QQcmdZViewItem

livemusic said:

...projecting the slider weight vector on its axle, you have the side componet of the slider weight, which is driving crazy your arm. This is unstable system: the further slider moves away from the bearing center, the more side force is.

This makes sense. I wonder how the ET2 pulled it off.

livemusic said:

That's why I'm saying the only way to build good high pressure/stiffness air arm is to make lightweight symmetrical slider/bearing/arm assembly and leave heavy shaft fixed firmly on its place.

Your probably right about this. If I go back to the design, I'll most likely try this approach; looking for a very small, torsionally flexible air line with some sort of set-up that allows it to pivot. In that case, the 1/4" bearing might be preferable.

My compressor is rated at 43 dB. It is OK when I put it in the basement except for when it reaches its maximum pressure setting. It then has some sort of release that causes a loud hissing that must be much higher than 43 dB. If the pump ran continuously it would probably be acceptable. I wonder if the airbrush pumps have such a release valve.

the biggest difference is weight. As far as I know ET use a hollow tube.I wonder how the ET2 pulled it off.

In my experience presure and airflow are strongly related. Even the smallest aquariumpump is capable off quite high presure as long as the airflow is kept sufficiently low. In other words the amount of airflow needed restricts the pressure a certain pump is able to deliver. Therefore putting two pumps in parallel means you can double the airflow at a certain pressure, but at the same time if the airflow through the airbearing exceeds what one pump can deliver at a given pressure, two pumps might be able to keep the pressure at the desired level.Would I get more PSI if I added a second aquarium pump feeding my surge tank? Or would the pressure just be limited by whichever pump created the least pressure?

(Kuzma state in the manual their the arm needs about 4 bar at 4 liters of air per minute).

Really nobody that knows the answer to this one?does anyone know how to calculate airflow for a given presure and airgap (and whatever else you need to know)

Look here:does anyone know how to calculate airflow for a given presure and airgap (and whatever else you need to know)

http://www.efunda.com/formulae/fluids/calc_orifice_flowmeter.cfm

Just calculate your air gap area and put the equivalent circular hole diameter into calculation - this shall give you reasonably good approximation (fluid density and flow coefficient are already set for air).

Thanks Livemusic!

It seems to be what I was looking for. (too bad you can only use it a few times before it shuts you out, but I found it will work again next day)

- Status

- Not open for further replies.

- Home

- Source & Line

- Analogue Source

- To all Ladegaard builders