Hello,

can you tell me, how you do mount toroidal transformers into a rack enclosure?

I know, with the bolt, rubber pads and steel washer. But, for do it this way I need to drill the chassis and the bolt has a big head, and If you mount the rack into cabinet with other devices, this will be a problem with the bolt.

Any advice?

Thanks!!

can you tell me, how you do mount toroidal transformers into a rack enclosure?

I know, with the bolt, rubber pads and steel washer. But, for do it this way I need to drill the chassis and the bolt has a big head, and If you mount the rack into cabinet with other devices, this will be a problem with the bolt.

Any advice?

Thanks!!

A bracket from a side or front/back of the enclosure? Or a countersunk bolt if the base is thick enough to accommodate (nut fastened inside)

Mount the toroid on a square plate, then mount the plate on 4 spacers to the chassis bottom.

Spacers should be higher than the toroid's bolt head.

Spacers should be higher than the toroid's bolt head.

Last edited:

With mounting toroidal hardware, two large rubber washers, two circular plates and a central bolt nut and spring washer is usually provided.

Although most would consider this as job done, you need to also source a insulation washer that includes the central bolt thread, to isolate chassis ground from the central bolt. This is rarely provided - along with sufficient thread length to do the job properly. See creepage and clearance Electrical Safety Requirements

Another precaution rarely observed, is caution when using toroidals particularly small ones in circuits with very little current draw, as flux density is greatest with no load.

Transformers Part 1 - Beginners' Guide to Electronics

Although most would consider this as job done, you need to also source a insulation washer that includes the central bolt thread, to isolate chassis ground from the central bolt. This is rarely provided - along with sufficient thread length to do the job properly. See creepage and clearance Electrical Safety Requirements

Another precaution rarely observed, is caution when using toroidals particularly small ones in circuits with very little current draw, as flux density is greatest with no load.

Transformers Part 1 - Beginners' Guide to Electronics

Last edited:

From the other forum:

> It's possible to upload some photos?

Of what? A dimple? A wrench socket? A bolt?

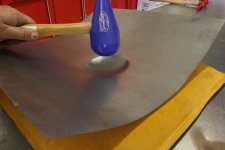

The "big money" is in tapered dimples. Lots of tapered dimple-dies for that job.

You only need a flat dimple bigger than your bolt+wrench, deeper than your bolt head, and nobody will see it. You can do a respectable job with two sockets and bolt or hammer. (You can even use a round rock on sand, but it takes a steady hand.)

> It's possible to upload some photos?

Of what? A dimple? A wrench socket? A bolt?

The "big money" is in tapered dimples. Lots of tapered dimple-dies for that job.

You only need a flat dimple bigger than your bolt+wrench, deeper than your bolt head, and nobody will see it. You can do a respectable job with two sockets and bolt or hammer. (You can even use a round rock on sand, but it takes a steady hand.)

Attachments

-

MS-DT1.png48.8 KB · Views: 571

MS-DT1.png48.8 KB · Views: 571 -

033-Bodywork-tips-and-tricks-lpr.jpg129.1 KB · Views: 529

033-Bodywork-tips-and-tricks-lpr.jpg129.1 KB · Views: 529 -

dimple-dies_1024x1024.jpg49.3 KB · Views: 528

dimple-dies_1024x1024.jpg49.3 KB · Views: 528 -

12-02855.jpg21.8 KB · Views: 539

12-02855.jpg21.8 KB · Views: 539 -

jbrc4008JBRC4008.jpg12.1 KB · Views: 540

jbrc4008JBRC4008.jpg12.1 KB · Views: 540 -

91084100_L_44ee484b-7cc6-4489-8160-c6f69bc52460.jpg14 KB · Views: 145

91084100_L_44ee484b-7cc6-4489-8160-c6f69bc52460.jpg14 KB · Views: 145 -

original.jpeg416.1 KB · Views: 171

original.jpeg416.1 KB · Views: 171 -

81BrY7-aNqL._SL1500_.jpg162.8 KB · Views: 149

81BrY7-aNqL._SL1500_.jpg162.8 KB · Views: 149 -

7a771e2d-3aaf-4da7-919c-2d78c0e9cf9d.jpg98.3 KB · Views: 147

7a771e2d-3aaf-4da7-919c-2d78c0e9cf9d.jpg98.3 KB · Views: 147 -

019-Bodywork-tips-and-tricks-lpr.jpg123.6 KB · Views: 241

019-Bodywork-tips-and-tricks-lpr.jpg123.6 KB · Views: 241

You could even flatten the prongs on a 'T-nut' -- the type used inside speaker cabinets to secure a driver -- then have a relatively thin (1.5mm or so) protrusion on the outside chassis bottom.

I did a kind of base with freecad and print with a 3d printer. I think it's better to countersunk M3 bolts than M6.

What do you think?

torid2 — imgbb.com

toroid — imgbb.com

What do you think?

torid2 — imgbb.com

toroid — imgbb.com

Make REALLY sure that you don't inadvertently make a single shorted turn around the core (with bolt and mounts) -- could get quite exciting.

Maybe he was thinking of the more-common 'bolt mounted to the bottom plate', forgetting that your mounting plate/post will insulate.

Hey, that creation is beeeautiful! Wouldn't be surprised if you get a bunch of requests from folks here that want them, too!

If you decide to produce them, you might want to consider a filet around the foot of the post -- less likely to snap off if the equipment ever gets dropped. Since you're 3D printing them the extra complexity doesn't cost much.

Great work,

Rick

Hey, that creation is beeeautiful! Wouldn't be surprised if you get a bunch of requests from folks here that want them, too!

If you decide to produce them, you might want to consider a filet around the foot of the post -- less likely to snap off if the equipment ever gets dropped. Since you're 3D printing them the extra complexity doesn't cost much.

Great work,

Rick

Last edited:

Thanks for the advice!

The idea was only for my mounts, but who knows... I take it in consideration.

Thanks again.

The idea was only for my mounts, but who knows... I take it in consideration.

Thanks again.

- it looks great!I did a kind of base with freecad and print with a 3d printer. I think it's better to countersunk M3

- Home

- Amplifiers

- Power Supplies

- Tips for mount toroidal transformer