I feel quite fortunate. Of course I've wanted a Threshold amp for years, but never thought it would happen. Along came Kolledog with a damaged project amp - a painful sight for most of us. Long story short, I ended up with the amp. Thanks again Kolledog - you are very reasonable, honest, and a nice fella!

Threshold S/500 project

Things are very busy for me right now, everything from a broken house to a broken body 🙂. Still, my goal was to give it a quick tear down and see if i could get it going.

The PSU can caps were thought to be bad, and at least of a voltage less than adequate. The amp did not work, and as can be seen in the swap meet thread was abused by a shipper.

I tested the caps and found no evidence that they had vented - but was still worried about the voltage rating. The rails were at around +/- 76V and the caps rated for 75V continuous, 95V surge... mmm.

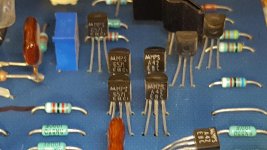

The amp was developing no bias and no heat. First thing was to test/replace the electrolytics on the input board, and toss the popcorn tants for films. I used what I had in the drawer - I really didn't want to leave it apart for too long right now. When I was done I could bring the bias in and tune up the heat 🙂

Next were the cosmetics. I reversed the front handle and put the scratches on the bottom. Straightened the heatsinks with large c-clamps and 10mm Alu stock. Sort of made a heatsink sandwich with 10mm alu stock as the bread with the heatsink fin as the meat, then squeezed the bread until the meat was straight. Each side of the amp is made of four identical sinks - they are the same in every way including tapping and drilling. I re-arranged them as to hide any defects on the bottom and behind the front cover.

The amps top cover had been painted in what seemed to be truck bedliner material. All rubbery and clogging the vents. It took several soakings in paint stripper to clean it off, along with some mechanical help. This was followed by linear brushing with 60 grit sandpaper and a lye bath to give it a natural gray finish.

Threshold S/500 project

Things are very busy for me right now, everything from a broken house to a broken body 🙂. Still, my goal was to give it a quick tear down and see if i could get it going.

The PSU can caps were thought to be bad, and at least of a voltage less than adequate. The amp did not work, and as can be seen in the swap meet thread was abused by a shipper.

I tested the caps and found no evidence that they had vented - but was still worried about the voltage rating. The rails were at around +/- 76V and the caps rated for 75V continuous, 95V surge... mmm.

The amp was developing no bias and no heat. First thing was to test/replace the electrolytics on the input board, and toss the popcorn tants for films. I used what I had in the drawer - I really didn't want to leave it apart for too long right now. When I was done I could bring the bias in and tune up the heat 🙂

Next were the cosmetics. I reversed the front handle and put the scratches on the bottom. Straightened the heatsinks with large c-clamps and 10mm Alu stock. Sort of made a heatsink sandwich with 10mm alu stock as the bread with the heatsink fin as the meat, then squeezed the bread until the meat was straight. Each side of the amp is made of four identical sinks - they are the same in every way including tapping and drilling. I re-arranged them as to hide any defects on the bottom and behind the front cover.

The amps top cover had been painted in what seemed to be truck bedliner material. All rubbery and clogging the vents. It took several soakings in paint stripper to clean it off, along with some mechanical help. This was followed by linear brushing with 60 grit sandpaper and a lye bath to give it a natural gray finish.

Attachments

Last edited:

Now that the bias was up, the rails dropped to +/- maybe 73V. Still close, but i will risk it for a bit or maybe forever.

I found no evidence of damaged semiconductors. Some resistors looked a little heat stressed but there was nothing I could find that was out of whack.

Offset was low, can't remember now but maybe 10mv each side.

Put it on the scope and sine and square looked good to this lousy eye.

It looks like someone was messing with the zobel networks. Not sure yet what to do about that. I will be going back in when there is more time. We can talk about it then.

Took it in the house. Right now i have Klipsch Forte II which I have been enjoying with low power class A amps. I wasn't expecting to like the combo.

I liked it a lot. The Forte II's 98dB keeps the 250w amp power low, and I would think it barely leaves Class A under normal conditions ...it rivals my aleph and M2 clones (almost) BUT BUT It's the bass and transients that can be stunning. It is sweet but can knock your socks off at the same time.

When I go back in I'm going to ask for some ideas. Thanks again Kolledog.

I found no evidence of damaged semiconductors. Some resistors looked a little heat stressed but there was nothing I could find that was out of whack.

Offset was low, can't remember now but maybe 10mv each side.

Put it on the scope and sine and square looked good to this lousy eye.

It looks like someone was messing with the zobel networks. Not sure yet what to do about that. I will be going back in when there is more time. We can talk about it then.

Took it in the house. Right now i have Klipsch Forte II which I have been enjoying with low power class A amps. I wasn't expecting to like the combo.

I liked it a lot. The Forte II's 98dB keeps the 250w amp power low, and I would think it barely leaves Class A under normal conditions ...it rivals my aleph and M2 clones (almost) BUT BUT It's the bass and transients that can be stunning. It is sweet but can knock your socks off at the same time.

When I go back in I'm going to ask for some ideas. Thanks again Kolledog.

Attachments

Last edited:

I recall seeing that original posting and feeling very saddened by the tragic tale, thanks for sharing your restoration story and hope whatever else you have going on works out for the best. Congrats and we'll done!

.. dB

.. dB

The S/500 II I used to own - and now being used by a friend driving Maggies - had gray electrolytics, not blue.

An externally hosted image should be here but it was not working when we last tested it.

that depended strictly from Papa's mood on specific day ........ "today we gonna use all gray caps!"

You have to break up the monotony 🙂

Is seems like these cans are/were sort of a commodity. I think the gray caps were Mepco / Centra and blue were Sprague or Mallory. Now CDE. All good.

The caps in my amp are not original.

Is seems like these cans are/were sort of a commodity. I think the gray caps were Mepco / Centra and blue were Sprague or Mallory. Now CDE. All good.

The caps in my amp are not original.

I was looking at that amp. I’m glade you got it. You got a lot farther then I would have lol

Great work and good luck with that beast

Great work and good luck with that beast

I always wanted to recap my old S/500 but it would have put my own stereo down for a few weeks while I disassembled, ordered parts, replace, and reassemble. Either way, those main power caps must have a heck of a life span given they are still churning along today in my friend's stereo!

There aren't many caps in there. Chances are that the small caps were in worse shape than the big ones.

One thing that I forgot to mention about these amps...

They are well engineered for repair. The entire assembly can be 'unfolded' without much risk or effort. Nice job- whoever made the thing.

🙂

One thing that I forgot to mention about these amps...

They are well engineered for repair. The entire assembly can be 'unfolded' without much risk or effort. Nice job- whoever made the thing.

🙂

Last edited:

yup

just finished these days major re-haul and un-gremlin of venerable Onkyo M200 and P200 (30 or so yrs old)

two handfuls of small caps and death diodes , few TO-92 , while big caps are still ok

good , not so easy to replace those special sized 30mF/90V Onkyo jobbies

speaking of ....... that's 220W/channel amp ; comparing build quality , dimensioning etc. - your amp is looking as 33KW/channel amp , comparing to funny Onkyo ....... and that one was once Brand Flagship

just finished these days major re-haul and un-gremlin of venerable Onkyo M200 and P200 (30 or so yrs old)

two handfuls of small caps and death diodes , few TO-92 , while big caps are still ok

good , not so easy to replace those special sized 30mF/90V Onkyo jobbies

speaking of ....... that's 220W/channel amp ; comparing build quality , dimensioning etc. - your amp is looking as 33KW/channel amp , comparing to funny Onkyo ....... and that one was once Brand Flagship

- Home

- Amplifiers

- Pass Labs

- Threshold S/500 saved