I just grabbed Thorens TD166 in pretty bad shape, cheap. One motor winding blown, repaired now. Badly scratched faceplate, had to completely sand it down to bare aluminum. There was no headshell, and I was amazed that it goes for as much as 85eur on ebay! That was it, I had to buy a 3d printer and make one of my own.

Well done.

Yes parts for these, and the TT istself are fetching prices well beyond their sonic value.

What did you pay for yours. I ran into one once that set me back $4 CAD (and included 2 carbon fibre brushes). I grabbed it and ran :^)

dave

Yes parts for these, and the TT istself are fetching prices well beyond their sonic value.

What did you pay for yours. I ran into one once that set me back $4 CAD (and included 2 carbon fibre brushes). I grabbed it and ran :^)

dave

Very nice work. Are you aware of anyone who prints headshells for customers?

I have a Grace arm that needs help.

I have a Grace arm that needs help.

You beat me by $2. I picked up an old Dual years ago at a garage sale for cleaning records.🙂I ran into one once that set me back $4 CAD (and included 2 carbon fibre brushes). I grabbed it and ran :^)

jeff

Haha, not even close to that! I paid 60eur for it.Well done.

Yes parts for these, and the TT istself are fetching prices well beyond their sonic value.

What did you pay for yours. I ran into one once that set me back $4 CAD (and included 2 carbon fibre brushes). I grabbed it and ran :^)

dave

I noticed there are no fuses protecting the motor, and I already repaired it once. Next time I might not be so lucky. I placed a 100ma slow blow fuse in series now, but not sure if that’s good enough. Any recommendations?

I'd wonder about the hum pickup with a headshell that's not grounded and metallic. Bringing a hand near the cartridge usually can be heard as extra hum even with a metal headshell. But it looks great. I believe you can get conductive sprays that might be suitable for coating the underside of the headshell if this is an actual issue.

I don’t have a record yet to test it, but I can tell you already that there is zero noise when everything is on, hand or no hand.I'd wonder about the hum pickup with a headshell that's not grounded and metallic. Bringing a hand near the cartridge usually can be heard as extra hum even with a metal headshell. But it looks great. I believe you can get conductive sprays that might be suitable for coating the underside of the headshell if this is an actual issue.

Curious to learn what the "sonic value" of the TD 166 is.

Few products in the history of audio are more solidly engineered and offer more value for money than the Thorens 160/165/166 i.m.o.

Few products in the history of audio are more solidly engineered and offer more value for money than the Thorens 160/165/166 i.m.o.

Certainly reasonable engineering. We sold MANY. Not because of superior performance, but because of the name.

dave

dave

We had a dozen tables (at least) set up with same arm & cart (if they didn’t come with one, the Thorens did not sound as good as the others (with the stock arm or a better one installed — i have done literally something like a 100 arm swaps on TD 145/160/165. BTW i rate 160>165>145.

dave

dave

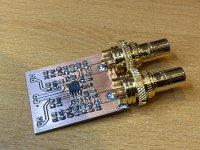

I tried to build a 10X amp into a headshell years ago but we did not have the kinds of MT back then. ( late 70's) So I put a Hafler preamp board in the base of my old Thornes. I put a Grace arm on mine.RIAA amp to be built in inside.

- Home

- Source & Line

- Analogue Source

- Thorens TD166 restoration, new headshell from scratch