Haha, I know its old video and I am slow... But its cool to see this is how they made the toroidal transformer we use.

toroidal winding machine -toroidal winder -current transformer winding machine winding machine - YouTube

Imagine doing this by hand!! It would have been a crazy task.

I challenge anyone to try fitting this into your amp!!

Напольный станок тороидальной намотки для особо крупных размеров - YouTube

toroidal winding machine -toroidal winder -current transformer winding machine winding machine - YouTube

Imagine doing this by hand!! It would have been a crazy task.

I challenge anyone to try fitting this into your amp!!

Напольный станок тороидальной намотки для особо крупных размеров - YouTube

Nice!

Oddly enough, I've noticed that all the workers at transformer facilities, including the ones in your first video, are women, Jensen transformers employs almost all women, I also saw a video of McIntosh amps, and the person in charge of winding the transformers is a woman How It's Made - McIntosh Tube Amp - YouTube. It seems to be the norm in general in the electronics manufacturing industry that the mayority of workers/assemblers are women. Perhaps women have better manual skills?

Oddly enough, I've noticed that all the workers at transformer facilities, including the ones in your first video, are women, Jensen transformers employs almost all women, I also saw a video of McIntosh amps, and the person in charge of winding the transformers is a woman How It's Made - McIntosh Tube Amp - YouTube. It seems to be the norm in general in the electronics manufacturing industry that the mayority of workers/assemblers are women. Perhaps women have better manual skills?

Last edited:

Hmm...I think maybe its patience. You cannot rush the job. I don't have the patience to wait there for the thing to complete and repeat....lol....

I guess these are the chinese "sweat shops" producing components... I saw fans and windows opened.... Must be really hot during summer.

I guess these are the chinese "sweat shops" producing components... I saw fans and windows opened.... Must be really hot during summer.

Last edited:

Also applies to Celestion speakers, Marshall amplifiers and most everywhere else.Nice!

Oddly enough, I've noticed that all the workers at transformer facilities, including the ones in your first video, are women, Jensen transformers employs almost all women, I also saw a video of McIntosh amps, and the person in charge of winding the transformers is a woman How It's Made - McIntosh Tube Amp - YouTube. It seems to be the norm in general in the electronics manufacturing industry that the mayority of workers/assemblers are women. Perhaps women have better manual skills?

Excellent manual skills is one point but I guess a very important one is that women stand better very repetitive jobs.

Also in general do not work alone but in groups, and certain type of jobs allow them to talk to each other, they are also multitaskers by nature so half the brain (just to say a figure) is focused on the job, other half can talk to others or think something unrelated, that helps them stand better long boring hours; men are way more focused, individual and goal oriented and get mad at boring repetitive jobs, if possible want renewed challenges.

Not a blanket statement of course, there is lots of variation in each sex.

In the early 70´s, when I was studying Engineering, part of the practical side of Classes was working part time at different Factories.

I worked at a Philco Ford factory making car radios.

60 girls in a large room, seated side by side in long tables, populating PCBs and assembling AM, pushbutton tuned car radios.

Didn´t miss a beat, work was high quality, but boy, how they chatted!!!

In a way smaller room, 3 male techs (I was considered to be at Tech level then, still far from graduating) tuned them, adjusted local oscillators, aligned IFs, but most important, *troubleshooted* them.

IF somebody talked to you while focused solving some problem, it was *annoying*, NO multitasking at all but 100% concentrated on *that* problem.

Girls worked well, but, say, 1% of radios had some problem, typically a solder bridge or solder around the pad "ring" but not actually soldered to component leg.

Did we minutely look at ALL of them with a loupe or resolder every pad hoping to solve it?

No way!! TOO slow and uncertain.

Based on symptoms we guessed the problem area, what functional block might be involved, measured or scoped and focused *there*.

Different mindsets , each adapted to a particular set of skills, both necessary.

A few examples:

Marshall factory:

Celestion Voice Coil winders:

Eminence:

Last edited:

Nah, that's just for the chokes in an Altec Voice-of-the-Theater passive crossover!!I challenge anyone to try fitting this into your amp!!

Напольный станок тороидальной намотки для особо крупных размеров - YouTube

That is a Beast of a transformer!

I know that O or Round-Core transformers are a thing but havent seen them used much.

So, if you were to build that sized beast, would you save on expensive copper wire with the corners missing?

I love these! R-Cores

R Core winding machine - YouTube

I know that O or Round-Core transformers are a thing but havent seen them used much.

So, if you were to build that sized beast, would you save on expensive copper wire with the corners missing?

I love these! R-Cores

R Core winding machine - YouTube

Haha, I know its old video and I am slow... But its cool to see this is how they made the toroidal transformer we use.

Coincidence, I was just about to ask a toroidal transformer question so I will try here first.

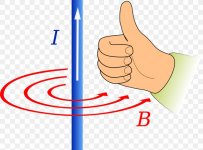

A toriodal transformer wound like the first video will create an external field from the nett loop of current around the circumference of the core.

Like this

Anyone know of a manufacturer who winds so as to cancel this out and eliminate the stray filed?

Best wishes

David

Coincidence, I was just about to ask a toroidal transformer question so I will try here first.

A toriodal transformer wound like the first video will create an external field from the nett loop of current around the circumference of the core.

Like this

Anyone know of a manufacturer who winds so as to cancel this out and eliminate the stray filed?

Best wishes

David

Oh this one, you can use fleming's rule.

Attachments

I know the rule, the question is - does any manufacturer bother to cancel this stray field caused by the current loop of the simple wind?

Best wishes

David

Best wishes

David

I know the rule, the question is - does any manufacturer bother to cancel this stray field caused by the current loop of the simple wind?

Best wishes

David

Oh ok. A perfect toroid transformer will have 0 magnetic field outside the ring. Of course, this is not possible in reality. However, itts still very low.

There is no practical way to cancel out this magnetic field. The easiest way would be to shield it using ferrous metal such as iron or steel.

It has been shown that female brains on average can multitask somewhat better than male ones.

Winding complex output transformer layers is better done by a woman.

Yes, I will admit it as a 50 year old man.

Winding complex output transformer layers is better done by a woman.

Yes, I will admit it as a 50 year old man.

...There is no practical way to cancel out this magnetic field....

This is simply incorrect, even Wikipedia shows three ways Toroidal inductors and transformers - Wikipedia and they are not the only possibilities, for instance a properly done double wind would work.

I haven't seen the last one but it is fairly obvious so it's probably been tried.

Best wishes

David

This is simply incorrect, even Wikipedia shows three ways Toroidal inductors and transformers - Wikipedia and they are not the only possibilities, for instance a properly done double wind would work.

I haven't seen the last one but it is fairly obvious so it's probably been tried.

Best wishes

David

Oh what i meant is that it is not possible to reduce the magnetic field outside the toroid to become 0. Whatever we do, it can only reduce it. Just like copper purity, 100% is not possible, but we can get to 5n or 7n etc.

> I’ve heard it’s because women will complain less about tedious/monotonous work.

There is an academic book/thesis which is nominally about electronics assembly, cities, and women electronics workers. Capital Moves

IMHO, having lived through the last dregs of RCA-Camden, he misses as much as he covers. There was a LOT of small assembly in Camden and everywhere before RCA bought the Victor Works. We have pictures of men woodworkers in Victor but who assembled mica soundheads? Painted flourishes? Who assembled Esterbrook pens uptown from Victor? The book's "axe" is that if the women in one city get organized and uppity, you beat them a while and then leave town. Bloomington was gonna be the next Camden but went sour. Nashville got ugly. Mexico promised to keep low-pay peace in Juarez, and did, until Japan ate the entire TV business (and in turn, Korea and China ate Japan's lunch).

There is an academic book/thesis which is nominally about electronics assembly, cities, and women electronics workers. Capital Moves

IMHO, having lived through the last dregs of RCA-Camden, he misses as much as he covers. There was a LOT of small assembly in Camden and everywhere before RCA bought the Victor Works. We have pictures of men woodworkers in Victor but who assembled mica soundheads? Painted flourishes? Who assembled Esterbrook pens uptown from Victor? The book's "axe" is that if the women in one city get organized and uppity, you beat them a while and then leave town. Bloomington was gonna be the next Camden but went sour. Nashville got ugly. Mexico promised to keep low-pay peace in Juarez, and did, until Japan ate the entire TV business (and in turn, Korea and China ate Japan's lunch).

In the mid 80's, I was responsible for designing the product and process in a military semiconductor module manufacturing line. The workers were all women, very few spoke English, all Spanish.

The lead woman spoke both.

I presently work with some of the best techs on this planet, making the most advanced things on this planet... they are no match to the talents and abilities of those women that I couldn't even talk to.

The women had tactile skills unmatched by most men I have worked with for the last 25 years.

Jn

The lead woman spoke both.

I presently work with some of the best techs on this planet, making the most advanced things on this planet... they are no match to the talents and abilities of those women that I couldn't even talk to.

The women had tactile skills unmatched by most men I have worked with for the last 25 years.

Jn

I wind my own toroids by hand, it's fine, pop on some music, crack on and before you know it's done. Remember toroids have more volts for less turns, HT windings are wound bifilar, so half the number of turns. the last one I wound I wound twice due to a screwup, when I rewound it it took about 8 hours, that's four heater wndg's @ 6.3v, two CT, two aux of 29v, bias = 0 100v, 80v tap. HT 0 300v ish /2. 15 0 15v for preamp. 0 12v for fan PSU.

The thing that takes the most time is insulating between windings with kapton tape. Each turn has to be put on separately as you can't get the tape though the center hole, so, one turn, cut. Next turn, cut, and so on. I have more time than money, and hate spending what bit I have, so don't have £300 + to splash on a custom wound toroid. Easy peasy.

Andy.

The thing that takes the most time is insulating between windings with kapton tape. Each turn has to be put on separately as you can't get the tape though the center hole, so, one turn, cut. Next turn, cut, and so on. I have more time than money, and hate spending what bit I have, so don't have £300 + to splash on a custom wound toroid. Easy peasy.

Andy.

Most of the time when I’m rewinding a toroid it’s already got one of the secondaries I need so it’s just a matter of adding the rest. Other times I get something that has useless secondaries for cheap so scrapping them and starting over isn’t a big deal. I did manage to get non adhesive Mylar tape from Tape-rite, which did make the outer tape go much faster last time. Use the same shuttle you use for the wire. It wasn’t cheap, but less expensive than the starting toroid (1500 VA Antek). I think you can get non adhesive kapton from Grainger, and I may also try that. Either way is about $20 a roll. For smaller less critical winds, I have just used black friction tape, and just squeezed a partial roll thru the hole. But it will make a gooey mess if you ever want to re-do it.

I always thought that winding your own transformer is considered the ultimate DIY, there is a lot of science behind a good transformer, perhaps not so important in a power transformer if your goal is just to obtain a certain output level and keep the transformer from burning, but the science is much more important in signal transformers, achieving a wide bandwidth, flat response and low distortion is not an easy task.

- Home

- Amplifiers

- Power Supplies

- This is how they make torroids!! Cool!!