maybe a really dumb question but i could not find any answers. because for my test with shrink plastic i used some random foil of approx 22 micron. does thinner foil increase sensitivity ? this thick foil reaches 20Khz so i dont see any other benefits of using thinner and thinner. if it does increase sens, that would be awesome

Hi,

all films of 6µm and thicker have a upper bandwidth limit of <20kHz due to their mass.

If You reach to 20kHz with thicker films You probabely make use of the stray-inductance-related resonance effect.

Sonically thicker films show lower resolution of finest details -but still way ahead of dynamic speakers.

The efficiency is not directly affected within the audio range, but indirectly You may apply much higher tensioning forces, resulting in a higher base resonance frequency and less mechanical offset when Bias is applied, which allows to increase the Bias, which increases the SPL.

Or the high tension allowed for smaller d/s distances which also increases SPL.

The high tension also allws to drive the panel harder.

jauu

Calvin

all films of 6µm and thicker have a upper bandwidth limit of <20kHz due to their mass.

If You reach to 20kHz with thicker films You probabely make use of the stray-inductance-related resonance effect.

Sonically thicker films show lower resolution of finest details -but still way ahead of dynamic speakers.

The efficiency is not directly affected within the audio range, but indirectly You may apply much higher tensioning forces, resulting in a higher base resonance frequency and less mechanical offset when Bias is applied, which allows to increase the Bias, which increases the SPL.

Or the high tension allowed for smaller d/s distances which also increases SPL.

The high tension also allws to drive the panel harder.

jauu

Calvin

hmm then i have to increase bias or get dc spacing lower, still why does a film of 22 micron does not have lower spl then a 6 micron ? is this because both a lighter then the air it moves ?

I have not found that using a thinner Mylar or increased tension to increase the efficiency.

This solely a function of the applied voltages and Diaphragm displacement/area.

I have found that the added mass does however decrease the micro detail of the sound.

Maybe by a measured standpoint this is could be just a slight reduction of the extreme high end frequency response of the output.

But it was only after an A&B test of two otherwise exactly identical panels did I actually notice a difference.

Although in my test I was using the same gauge of Mylar, but I was comparing two different coatings that each had a different mass and coating thicknesses, Licron and Licron Crystal.

In a test of when I first fired them up after seven years they had a coatin of sane and dirt on the diaphragms and this too was a noticeable difference after I had cleaned them.

But it was not enough of a difference to ruin the sound and all I had to do was boost the high end slightly with a 12Khz shelving EQ to match the panel that had not been cleaned to the one that had been cleaned.

Even my very First panels that used a much thicker Model airplane covering sounded great.

As I used that stuff to work out the bugs in my build process before I started using my good .25 mil Mylar.

Because what I have is what I have, and it is hard to get. 😉

I have found out that the thinner the Mylar that is used, it is harder to get enough tension on panels that are a bit wider of greater than 6" to 8" wide, and, even more can be an issue.

As this can/will cause stability issues especially at an increased Bias voltage.

I didn't have much of a problem with this, with my smaller 3" wide panels.

Except when the stator's exhibited some sort of imbalance in the electrical resistance of the stator coatings between the two halves.

As I did have this issue with some of my earlier painted stator versions.

Once again, once there was enough tension on the diaphragm all of my size versions stayed stable at any bias voltage that they could withhold (without arcing) between the stators and/or the diaphragm.

This included my 8.5" wide panels with various D/S spacings as I could change out different thickness of frames at anytime ranging from 1/16" to 1/8".

Then again, I have only used heat and have not explored a mechanical means of tensioning of the diaphragm yet.

But, I would guess that it is the lowest form of the amount of tension that one could use on a diaphragm.

jer 🙂

This solely a function of the applied voltages and Diaphragm displacement/area.

I have found that the added mass does however decrease the micro detail of the sound.

Maybe by a measured standpoint this is could be just a slight reduction of the extreme high end frequency response of the output.

But it was only after an A&B test of two otherwise exactly identical panels did I actually notice a difference.

Although in my test I was using the same gauge of Mylar, but I was comparing two different coatings that each had a different mass and coating thicknesses, Licron and Licron Crystal.

In a test of when I first fired them up after seven years they had a coatin of sane and dirt on the diaphragms and this too was a noticeable difference after I had cleaned them.

But it was not enough of a difference to ruin the sound and all I had to do was boost the high end slightly with a 12Khz shelving EQ to match the panel that had not been cleaned to the one that had been cleaned.

Even my very First panels that used a much thicker Model airplane covering sounded great.

As I used that stuff to work out the bugs in my build process before I started using my good .25 mil Mylar.

Because what I have is what I have, and it is hard to get. 😉

I have found out that the thinner the Mylar that is used, it is harder to get enough tension on panels that are a bit wider of greater than 6" to 8" wide, and, even more can be an issue.

As this can/will cause stability issues especially at an increased Bias voltage.

I didn't have much of a problem with this, with my smaller 3" wide panels.

Except when the stator's exhibited some sort of imbalance in the electrical resistance of the stator coatings between the two halves.

As I did have this issue with some of my earlier painted stator versions.

Once again, once there was enough tension on the diaphragm all of my size versions stayed stable at any bias voltage that they could withhold (without arcing) between the stators and/or the diaphragm.

This included my 8.5" wide panels with various D/S spacings as I could change out different thickness of frames at anytime ranging from 1/16" to 1/8".

Then again, I have only used heat and have not explored a mechanical means of tensioning of the diaphragm yet.

But, I would guess that it is the lowest form of the amount of tension that one could use on a diaphragm.

jer 🙂

Last edited:

why does a film of 22 micron does not have lower spl then a 6 micron ? is this because both a lighter then the air it moves ?

That is essentially it.

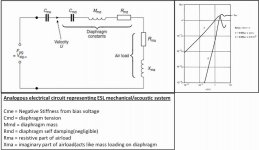

When modeling an ESL as an electro-acoustic circuit the diaphragm behaves like a mass(inductor Mmd).

The air is a bit more complicated, behaving like a resistor at high frequencies(Rma), and a mass(inductor Xma) at lower freqencies.

The air and diaphragm are in series in the model, and the impedance of the air components (Rma & Xma) dominates the current thru the circuit for all but the highest frequencies where the mass of the diaphragm (Mmd) begins to exceed that of the air resistance(Rma)

There is a simple formula to calculate when this roll off due to diaphragm mass starts.

Details at link below, along with some measurements compared to theory.

http://www.diyaudio.com/forums/plan...tatic-speakers-microphones-5.html#post3427260

As Calvin mentioned, if you are measuring response flat to 20Khz with heavier films this is due to some type of resonant boosting. It is most likely electrical resonance from the transformer leakage inductance and ESL capacitance. It could also be partially acoustic resonance from the cavity formed between the stators, especially if % open area is not 50% or greater.

Attachments

- Status

- Not open for further replies.