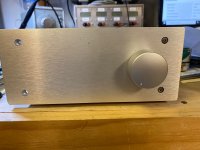

I am finishing a chip amp build and my front panel is too thick for the volume pot. I thought I would share my solution. I bought some bushings from Amazon for a 1/4" shaft, drilled the 3/8" OD hole in the face plate for the bushing with my drill press. Then I purchased a 4 1/2" shaft extension so I could mount the volume pot further back. I cut a small section of std issue HD al angle stock to mount the pot and secured it to the enclosure bottom with a bolt and some standoff washers. Turned out great and the volume knob feels smooth and substantial. The parts:

https://www.amazon.com/gp/product/B00MND99T0/ref=ppx_yo_dt_b_asin_title_o02_s00?ie=UTF8&psc=1

Dayton 12N973 $8.41 Shaft Extender Kit, 1/4 Dia x 4-1/2 L | Zoro.com

George

https://www.amazon.com/gp/product/B00MND99T0/ref=ppx_yo_dt_b_asin_title_o02_s00?ie=UTF8&psc=1

Dayton 12N973 $8.41 Shaft Extender Kit, 1/4 Dia x 4-1/2 L | Zoro.com

George

Attachments

I had this problem too. My solution was simpler! I fitted the pot and input selector to a spare piece of fibreglass pcb^, and then glued this with instant grab adhesive to the front panel - the shafts were long enough without any extension being needed.

(^the pcb was drilled for the bushes and not used to mount the switch and pot by soldering)

(^the pcb was drilled for the bushes and not used to mount the switch and pot by soldering)

That elegant concave volume know well on your front face plate would be a serious challenge in aluminum. I'm decent working with metal but nowhere near that good. lol. Looks cool.

George

George

I used a similar approach to the OP when I made a switcher. Bought some alumimuim rods from the hardware store and some couplers from China. I put the rods through holes drilled in wood and mounted to the case near the front panel so they were secure (with some lubricant for smooth action). The rotary switches, connected to these long rods, were mounted at the back of the case so they could be close to the RCA back panel sockets, so the cabling had minimal lengths.