Sorry! Not dead, have just been really busy. I've got tomorrow off work though, so should hopefully have time to at least try a battery on the heaters.

Part 54: The Hum Hunter Triumphant!

Just tested the amp with the battery on the 300b filament. It's absolutely silent! Thank you so much for helping to track this down.

I'm now thinking of splashing out for the tent labs filament supply to fix this once and for all. Are there any alternative filament regulators I should look at instead?

Just tested the amp with the battery on the 300b filament. It's absolutely silent! Thank you so much for helping to track this down.

I'm now thinking of splashing out for the tent labs filament supply to fix this once and for all. Are there any alternative filament regulators I should look at instead?

Brute Force DC:

6.3V filament transformer (rated for at least 3 Amps).

Schottky Bridge

20,000 uF

2 Ohm power resistor (adjust according to get 5V when the filament finally warms up)

20,000 uF

Worked for me, on different 300B amplifiers.

My mains power varies from 117VAC to 123VAC, I adjust the 2 Ohm resistance if necessary, to get 5V at 120VAC line.

That DC power features Soft Start, only 1mV - 2mV ripple, and Simplicity.

6.3V filament transformer (rated for at least 3 Amps).

Schottky Bridge

20,000 uF

2 Ohm power resistor (adjust according to get 5V when the filament finally warms up)

20,000 uF

Worked for me, on different 300B amplifiers.

My mains power varies from 117VAC to 123VAC, I adjust the 2 Ohm resistance if necessary, to get 5V at 120VAC line.

That DC power features Soft Start, only 1mV - 2mV ripple, and Simplicity.

Last edited:

Thanks 6a3Summer. I looked into trying this, but the parts aren't available locally, so I think I'm going to take the easy way out and use the off-the-shelf fix. Will try it in my next project (this is getting addictive).

The Coleman regulators have a significant advantage, isolation from power supply vagaries (but with a very small voltage overhead/cushion, for efficiency reasons), so should be considered as a future upgrade.

All good fortune,

Chris

All good fortune,

Chris

Thanks. I was only loosely aware of these before, but haven't ordered anything yet so will look into them.

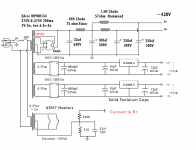

the output feedback grounding wire are not independent.

they connected together and then use a single long wire to connect to the ring ground.

suggest they connect to the ring ground separately.

suggest to reconsider the grounding arrangements.

This. You can't daily chain grounds like that.

I just build a 300B amp using this even less complicated DC for the filament supply and it's dead silent.

I did a whole video series on building the amp and discuss a lot of tip on how to avoid hum in amplifier layouts. I've never had hum in any of the amps I have built.

300B DIY Budget Tube Amplifier Build Series - YouTube

"The chassis is connected to safety earth (3 pin plug). The safety earth is connected to circuit ground by an 8 ohm power resistor bridged with a small capacitor."

Why would you do that? I always just solidly bolt the safety ground directly to the chassis as close to the power jack as possible.

"The solid green wire is safety earth from the aluminium panel that the input and output jacks are mounted to. It only connects to safety ground."

Again, why would you do that? You do have the RCA jacks insulated from that panel right?

I did a whole video series on building the amp and discuss a lot of tip on how to avoid hum in amplifier layouts. I've never had hum in any of the amps I have built.

300B DIY Budget Tube Amplifier Build Series - YouTube

"The chassis is connected to safety earth (3 pin plug). The safety earth is connected to circuit ground by an 8 ohm power resistor bridged with a small capacitor."

Why would you do that? I always just solidly bolt the safety ground directly to the chassis as close to the power jack as possible.

"The solid green wire is safety earth from the aluminium panel that the input and output jacks are mounted to. It only connects to safety ground."

Again, why would you do that? You do have the RCA jacks insulated from that panel right?

Attachments

Last edited:

To avoid ground loops when other devices also have their Audio GND connected directly to PE. I only connect Audio GND directly to PE in power amplifiers. In sources I "lift" Audio GND by means of a 10 Ohm resistor to PE. Sometimes in parallel with a 100 nF X2 capacitor. This way one achieves safety and no ground loop.

Last edited:

"The chassis is connected to safety earth (3 pin plug). The safety earth is connected to circuit ground by an 8 ohm power resistor bridged with a small capacitor."

Why would you do that? I always just solidly bolt the safety ground directly to the chassis as close to the power jack as possible.

"The solid green wire is safety earth from the aluminium panel that the input and output jacks are mounted to. It only connects to safety ground."

Again, why would you do that? You do have the RCA jacks insulated from that panel right?

As jean-paul has said, the possible issue is a ground loop. Safety earths *must* be connected directly to chassis. If signal grounds are also directly connected to chassis a loop can be formed from safety earths through signal interconnections between chassis'. The loop will inductively pick up stray room EMI and mix it into the non-zero impedance of the signal "grounds".

If everybody is plugged into a single local power strip, and nothing from the outside world (TV cable, HDMI, a remote subwoofer, etc.) is involved, then the loop is local enough and small enough to not be a noticeable problem. But that's not always the case.

Isolation of signal "grounds" from chassis (and safety earth) can be done with large paralleled both-polarities diodes and/or a large resistor, both with or without a shunt capacitor for some noisy situations. When jean-paul and I last discussed this, I had argued that the resistor was unnecessary if using diodes, but I was wrong. It keeps the average voltage between chassis and signal to zero, so should be included. Even a low wattage resistor is fine if using diodes.

All good fortune,

Chris

- Home

- Amplifiers

- Tubes / Valves

- The Odyssey of the Hum Hunter: part 52