I am very new to audio analyzers and I’m wanting to get a good setup. I have a Quantasylum QA403 and did my first amp measurements a couple of days ago. I quickly learned the need for good cables and connections. I couldn’t figure out why an amp I had just rebuilt was nearing a full percent of distortion at rated output. I guess 12 foot speaker cables and a very long rca cable wasn’t a good idea. With some changes I now have it reading 0.01% at output which is better than spec.

With knowing short cables are best I ordered a pair of 3 foot BNC to rca cables and plan on using 2-3 foot speaker cables to use from the amp to the load.

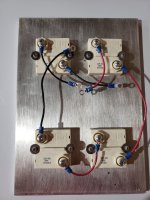

I bought these 1000w resistors years ago. I was told they were non inductive, but I’m thinking that isn’t the case.

Anyone familiar with this style of resistor? Is it okay, or pretty crummy? I think they’re known as “braking” resistors. On eBay you’ll see they’re advertised as non inductive.

I want to keep my options relatively cheap. I have this old aluminum inverter case. It measures 17 inches long, 8 inches tall and 6-1/2 inches wide. One of the end caps also has a fan built into it. So hopefully it would do well at keeping the temp down

My thought was to buy ten 100w resistors like these for each channel, 20 in total. If it could handle it then later down the road I would buy more so I could switch between 8 and 4 ohm.

https://www.digikey.com/en/products/detail/ohmite/AP101%2050R%20F/13909860?utm_adgroup=General&utm_source=google&utm_medium=cpc&utm_campaign=PMax Shopping_Product_Zombie SKUs&utm_term=&utm_content=General&utm_id=go_cmp-17815035045_adg-_ad-__dev-m_ext-_prd-13909860_sig-Cj0KCQiAhomtBhDgARIsABcaYynyMTcRWOEaDbMB2LMRXNDy_YbtueiUcIMC4K64U8_8LT2Ko0_yF3MaAh2CEALw_wcB&gad_source=1&gbraid=0AAAAADrbLlgfY-1O4jlSzA_HvUlx1PUR1&gclid=Cj0KCQiAhomtBhDgARIsABcaYynyMTcRWOEaDbMB2LMRXNDy_YbtueiUcIMC4K64U8_8LT2Ko0_yF3MaAh2CEALw_wcB

Clearly they can only handle their rated power with the help of a heatsink, I’m hoping mine can handle 2000 watts of heat. The case had roughly 40 MOSFETs on it for a 2500w inverter.

Does this all seem like a good plan or will in not see any difference from my current 1000w loads? As they are decent enough???

Dan

With knowing short cables are best I ordered a pair of 3 foot BNC to rca cables and plan on using 2-3 foot speaker cables to use from the amp to the load.

I bought these 1000w resistors years ago. I was told they were non inductive, but I’m thinking that isn’t the case.

Anyone familiar with this style of resistor? Is it okay, or pretty crummy? I think they’re known as “braking” resistors. On eBay you’ll see they’re advertised as non inductive.

I want to keep my options relatively cheap. I have this old aluminum inverter case. It measures 17 inches long, 8 inches tall and 6-1/2 inches wide. One of the end caps also has a fan built into it. So hopefully it would do well at keeping the temp down

My thought was to buy ten 100w resistors like these for each channel, 20 in total. If it could handle it then later down the road I would buy more so I could switch between 8 and 4 ohm.

https://www.digikey.com/en/products/detail/ohmite/AP101%2050R%20F/13909860?utm_adgroup=General&utm_source=google&utm_medium=cpc&utm_campaign=PMax Shopping_Product_Zombie SKUs&utm_term=&utm_content=General&utm_id=go_cmp-17815035045_adg-_ad-__dev-m_ext-_prd-13909860_sig-Cj0KCQiAhomtBhDgARIsABcaYynyMTcRWOEaDbMB2LMRXNDy_YbtueiUcIMC4K64U8_8LT2Ko0_yF3MaAh2CEALw_wcB&gad_source=1&gbraid=0AAAAADrbLlgfY-1O4jlSzA_HvUlx1PUR1&gclid=Cj0KCQiAhomtBhDgARIsABcaYynyMTcRWOEaDbMB2LMRXNDy_YbtueiUcIMC4K64U8_8LT2Ko0_yF3MaAh2CEALw_wcB

Clearly they can only handle their rated power with the help of a heatsink, I’m hoping mine can handle 2000 watts of heat. The case had roughly 40 MOSFETs on it for a 2500w inverter.

Does this all seem like a good plan or will in not see any difference from my current 1000w loads? As they are decent enough???

Dan

You don't want to introduce hum, so short input cables are a good idea. How the grounding is done matters. Are you measuring the signal right at the amp? You don't want to measure it at the load. The loads themselves shouldn't matter much. I've seen some non-inductive resistors that increased THD up at 20 kHz and above, but that's not where most people measure. Why in the world do you need 2000 W of capability?

I’m using cables that have a BNC to a pair of alligator clips to attach to the load, they’re about 3 feet long, does that seem like an okay length? I am measuring at the load, I will from now on measure at the amplifier output terminals. That is good to know! So it sounds like I should stick with the loads I have as it would be a waste of money?

I want to be able to test most any amp I’d need to their rated output. I have a few vintage amps rated to 500-600 watts at 8 ohms. I have a few newer amps rated at 925w at 8 ohms.

Dan

I want to be able to test most any amp I’d need to their rated output. I have a few vintage amps rated to 500-600 watts at 8 ohms. I have a few newer amps rated at 925w at 8 ohms.

Dan

Imho, set up an impedance measurement test jig, following REW help notes. Then measure a normal 1% 0.5W metal film (say 100 ohm), to confirm you have a flat response for gain/phase. Then measure your power resistors and cross your fingers.

Do you have a 4 or 5 digit DMM that measures resistance? If so, then measure the load resistance and keep measuring it while you heat the resistor up to say 50C, to see if there is a noticeable temperature coefficient.

Make connections from amp to load using lugged robust terminals at each end with at least 1mm2 wire of short length, so that temp rise and resistance of wiring/terminals are as low as practical.

Do you have a 4 or 5 digit DMM that measures resistance? If so, then measure the load resistance and keep measuring it while you heat the resistor up to say 50C, to see if there is a noticeable temperature coefficient.

Make connections from amp to load using lugged robust terminals at each end with at least 1mm2 wire of short length, so that temp rise and resistance of wiring/terminals are as low as practical.

One of these should expose about 8 ohm - no?

https://www.amazon.com/DERNORD-Fold...prefix=110v+6000w+element,aps,302&sr=8-5&th=1

230V, 28A, 6600W

https://www.digikey.com/en/resources/conversion-calculators/conversion-calculator-ohms

And a tank of water!

//

https://www.amazon.com/DERNORD-Fold...prefix=110v+6000w+element,aps,302&sr=8-5&th=1

230V, 28A, 6600W

https://www.digikey.com/en/resources/conversion-calculators/conversion-calculator-ohms

And a tank of water!

//

You would need special power service to support anything over 1500W into the amp.

Way back I have measured the resistance and impedance vs frequency of both the high grade 250W resistors and the cheap 100W resistors from eBay. The important takeaway is that the loop inductance of 3' of #12 zip cord was higher.

The HF stuff will be a combination of inductance and skin effect. Its possible but really hard to make wide band non-inductive resistors. http://www.ohm-labs.com/precision-shunts/ac-shunts.html

Way back I have measured the resistance and impedance vs frequency of both the high grade 250W resistors and the cheap 100W resistors from eBay. The important takeaway is that the loop inductance of 3' of #12 zip cord was higher.

The HF stuff will be a combination of inductance and skin effect. Its possible but really hard to make wide band non-inductive resistors. http://www.ohm-labs.com/precision-shunts/ac-shunts.html

"I tried those. They all fried at anything much over the rated limit. "

Did the bottom case temp exceed 85C with whatever heatsinking solution you used? Probably needed a milled heatsink base for starters if the total heatsink was trying to transfer 4x600=2400W.

Did the bottom case temp exceed 85C with whatever heatsinking solution you used? Probably needed a milled heatsink base for starters if the total heatsink was trying to transfer 4x600=2400W.

Its been 10 years. They were on a large heatsink. It was transient power that fried them. The peak current in that application was too high. Even if the average power was well within ratings. I think the peak current was 1000 A for 50 microseconds or around 200W and once per minute. They did not work for that and I looked pretty dumb for trying it. The carbon comp resistors went back in. (Velonex Surge generator). I'm sure those work well when within ratings and should be non-reactive to a pretty high frequency.

At 1000A you have to start worrying about the forces generated my the magnetic field bending/breaking things... Two wires carrying 1000A that are 1cm apart develop 200kg force per metre between them...

Yeah. The better power resistors will have peak power specs. It's often 3-5x the rated long-term dissipation.It was transient power that fried them. The peak current in that application was too high.

My dummy load is 20 x 0.8 Ω Dale RH-25 resistors on a heat sink. I bought the heat sink on ePay years ago. I think it came from a cellphone base station. It has a large flat area where I mounted the resistors and two temperature controlled centrifugal fans cooling it. I have the resistors configured for 2x8 Ω with taps at 4 Ω. That allows me anywhere from 1 Ω to 16 Ω at up to 500 W dissipated power by using various series/parallel combinations of the resistors.

The dummy load does a really good job of heating up my lab during long-term testing. 🙂

Tom

The impedances are very low, so I wouldn't worry about that. I'd worry more about the series resistance introduced by the cable. I'm considering rebuilding my dummy load with Neutrik speakON connectors and possibly some MOSFET switches to beef up the connection to the dummy load and allow for automatic/remote controlled impedance selection. I currently use banana jacks and they're not the greatest connector out there.You don't want to introduce hum, so short input cables are a good idea.

Are they long enough to reach? If so, the length would be okay.I’m using cables that have a BNC to a pair of alligator clips to attach to the load, they’re about 3 feet long, does that seem like an okay length?

I would connect from the output of the amp directly to the audio analyzer with a BNC cable and a BNC-Clip lead adapter. Connect the load with a speaker cable (12-14 AWG) and proper connectors.

Tom

Add 8 uS rise time and it gets quite interesting. This is the standard test for domestic surge protectors. And its representitive of what you can get off the utility power with a lightning strike nearby.At 1000A you have to start worrying about the forces generated my the magnetic field bending/breaking things... Two wires carrying 1000A that are 1cm apart develop 200kg force per metre between them...

- Home

- Design & Build

- Equipment & Tools

- The need to build a better dummy load for distortion measurements.