I've split this off from a HiVi B3S thread so the orginal thread is not hijacked.

http://www.diyaudio.com/forums/showthread.php?s=&threadid=106632

This is a comical little speaker made from a 100mm PVC T-piece. There's quite a deal of items in hardware stores that can be adapted for diy audio.

This speaker was to give me a break from a 3-way that's taken 6 weeks to design, 2 weeks to build, 2 weeks of revisions and still on going. Here was something that could be made in 2 days and I was after another speaker for the computer. The TB W3-871SC looked the goods and TB was a driver I wanted to try even though I don't do many fullranges. For Australians that are after TB drivers, check Darcher Audio.

http://www.darcheraudio.com.au/

Since the baffle diameter is only 117mm, BSC was a must as well as a zobel to tame the impedance from hell.

Actual pipe T was 3.3 litres (filled with water) so a design was done for near field use (<1.5m) in a small room.

Vb=3 litres, Fb=85Hz vented , ø30mm x 55mm port, F3=73Hz. In a small room there was enough bass so a small sub was not required as initially thought.

The front chamber is lined with felt and the back has an acoustic tile cut to size and folded in a vee. There doesn't seem to be an issue with the backwave and assume that's because of the very small driver Sd. The driver is offset on the baffle to assist in diffraction (mild at best) but to ensure distances are different to the inside surfaces from the driver.

As I've said previously, no dogs allowed with 10m. 😉

http://www.diyaudio.com/forums/showthread.php?s=&threadid=106632

This is a comical little speaker made from a 100mm PVC T-piece. There's quite a deal of items in hardware stores that can be adapted for diy audio.

This speaker was to give me a break from a 3-way that's taken 6 weeks to design, 2 weeks to build, 2 weeks of revisions and still on going. Here was something that could be made in 2 days and I was after another speaker for the computer. The TB W3-871SC looked the goods and TB was a driver I wanted to try even though I don't do many fullranges. For Australians that are after TB drivers, check Darcher Audio.

http://www.darcheraudio.com.au/

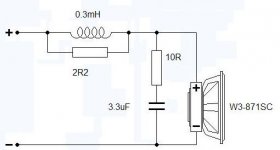

Since the baffle diameter is only 117mm, BSC was a must as well as a zobel to tame the impedance from hell.

Actual pipe T was 3.3 litres (filled with water) so a design was done for near field use (<1.5m) in a small room.

Vb=3 litres, Fb=85Hz vented , ø30mm x 55mm port, F3=73Hz. In a small room there was enough bass so a small sub was not required as initially thought.

The front chamber is lined with felt and the back has an acoustic tile cut to size and folded in a vee. There doesn't seem to be an issue with the backwave and assume that's because of the very small driver Sd. The driver is offset on the baffle to assist in diffraction (mild at best) but to ensure distances are different to the inside surfaces from the driver.

As I've said previously, no dogs allowed with 10m. 😉

Attachments

Hydrant crossover

Baffle step was required as due to the 117mm diameter baffle, the BS F3 would be around 1000Hz. A zobel is added to tame the Tb rising impedance curve and details can be seen in the attached xo.

I used 2dB BSC as it's being used not too far from a back wall, plus lowering the octaves above 1000Hz, gives an impression of a lower f3 as the bass SPL remains constant. Helps also with lower mids.

For other BSC on a 117mm baffle:

4dB, 3R9 + 0.6mH

6dB, 6R8 + 1.1mH

Baffle step was required as due to the 117mm diameter baffle, the BS F3 would be around 1000Hz. A zobel is added to tame the Tb rising impedance curve and details can be seen in the attached xo.

I used 2dB BSC as it's being used not too far from a back wall, plus lowering the octaves above 1000Hz, gives an impression of a lower f3 as the bass SPL remains constant. Helps also with lower mids.

For other BSC on a 117mm baffle:

4dB, 3R9 + 0.6mH

6dB, 6R8 + 1.1mH

Attachments

Did you treat the PVC with K9P? Oh wait, you said no dogs.

Love the idea. Have you been visiting with Andy Graddon by any chance? 😉

Love the idea. Have you been visiting with Andy Graddon by any chance? 😉

Cal Weldon said:Did you treat the PVC with K9P? Oh wait, you said no dogs.

Love the idea. Have you been visiting with Andy Graddon by any chance? 😉

Cal, you know that most DIYers mark their own territory first, generally after a few beers

and ask dave if cat-spray might be worse

Rabbitz, i just read your post, and think your design is pretty cool! I also have used pvc products for audio designs. After i quickly found that the 6 1/2 inch tri-axle drivers i placed in the rear deck of my car sounded hollow, & my subs were also beatting them up baddly, i thought to make some type of enclosures for them. I also found out very fast that the trunk spring would be in the way of any kind of conventional box, or pair of boxes. So, after trying a few options & a few "choice" words, i thought to try 6 inch diameter pvc pipe with a cap on the end to seal it . That didn't work too well, too long, and bulky. So i ditched the pipe, kept the end cap, and simply sealed it, & screwed right through the metal deck from the top side. I used a pair of screw-down terminals through the rear side of the cap. I then placed the insulated crossover network inside, made a spacer ring out of fiber board for between the deck & speaker, next the speaker top mounted & sealed ,and my problems were solved! 😀 What do you think, sound like a good solution?

Cal Weldon said:Love the idea. Have you been visiting with Andy Graddon by any chance? 😉

Yes Cal, I do a visit to Andy's to hear his new creations. I think there is something in the water around here. 😉

amphead123 said:What do you think, sound like a good solution?

I know didly about car systems and they operate in a hostile and poor environment. Sounds like you've made gains that you are happy with. The Loudspeaker Design Cookbook does have a section on car audio which may be of some use.

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Full Range

- The Hydrant... a PVC pipe TB W3-871 speaker