plysch,

The best damping technics is a constraint layer damping (CLD), when the soft layer is placed between two rigid ones. So, I have inserted my carbon tube into the larger diameter thin wall alu tube, and fill the gap with silicon RTV caulk. Inside the wand, I put a cocktail strow (for the leads) and fill again the gap with expanding foam. Note, that the headshell, bearing carriage and counterweight lever are rigidly coupled with the carbon tube only.

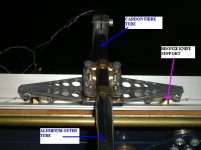

The bearing consists of two small hobby knife blades, bolted to the alu profile, and supported by the bronze planks. The whole assembly is prevented from lateral movement by two strings, having enough tension.

The best damping technics is a constraint layer damping (CLD), when the soft layer is placed between two rigid ones. So, I have inserted my carbon tube into the larger diameter thin wall alu tube, and fill the gap with silicon RTV caulk. Inside the wand, I put a cocktail strow (for the leads) and fill again the gap with expanding foam. Note, that the headshell, bearing carriage and counterweight lever are rigidly coupled with the carbon tube only.

The bearing consists of two small hobby knife blades, bolted to the alu profile, and supported by the bronze planks. The whole assembly is prevented from lateral movement by two strings, having enough tension.

Attachments

Livemusic, thanx alot, I will try to manage something like that.

Looks extreamly good by the way.

Looks extreamly good by the way.

Livemusic,

Why is glue a no-no in an arm?

I'm currently building an arm from a constraction of 6 mm wooden sqr being glue together. It is very stiff.

Thank

Izhak

btw- I'm from Haifa living in NJ for now until end of summer

Why is glue a no-no in an arm?

I'm currently building an arm from a constraction of 6 mm wooden sqr being glue together. It is very stiff.

Thank

Izhak

btw- I'm from Haifa living in NJ for now until end of summer

I'm currently building an arm from a constraction of 6 mm wooden sqr being glue together. It is very stiff.

It may seem stiff (6mm

)(that seems very thick!), but a carbon fibre rod will be a lot stiffer. Do a mental experiment: enlarge both arms one hundred times, and han a large weight from both. Which one will be stiffer???

)(that seems very thick!), but a carbon fibre rod will be a lot stiffer. Do a mental experiment: enlarge both arms one hundred times, and han a large weight from both. Which one will be stiffer???Remember pickup arms are all about very small forces, too small for us to really 'feel', but with a lot of impact!!

But don't let me disappoint you, go ahead with your contraption 🙂D 😉 ) and enjoy the music. Perhaps something for a project in the future? I still have to build mine, so don't let me bother you...

Hi Miniwatt,

I'm using 4 of these 6mm squars and spacing them about 30 mm apart (similar to constraction beams in buidings).

This gived a static hight of ~30 mm compered to a typical 10-15 mm in most tubes used for torarm. this makes it very stiff.

Regards

Izhak

I'm using 4 of these 6mm squars and spacing them about 30 mm apart (similar to constraction beams in buidings).

This gived a static hight of ~30 mm compered to a typical 10-15 mm in most tubes used for torarm. this makes it very stiff.

Regards

Izhak

Izhak shalom,

In our hobby, your own experience is an ultimate criterion, IMHO.

So, I'm speaking based on my trials and errors. I made once an arm wand from several layers of an aircraft grade 1.5 mm plywood glued together with the yellow carpenter glue; the inner cavities were stuffed with balsa. Great disappointment - this was the worst sounding arm I made, I could not tolerate the sound for one record side...

We are speaking here not about stifness is absolute terms, but rather about stiffness-to-weight ratio. I mean one should try to build the arm as stiff as possible for the given weight (rather light). The stiffer the arm, the higher its natural resonant frequency is. And higher frequencies can be damped much more easily.

Feel free to contact me if you are interested, when you are back to Israel.

In our hobby, your own experience is an ultimate criterion, IMHO.

So, I'm speaking based on my trials and errors. I made once an arm wand from several layers of an aircraft grade 1.5 mm plywood glued together with the yellow carpenter glue; the inner cavities were stuffed with balsa. Great disappointment - this was the worst sounding arm I made, I could not tolerate the sound for one record side...

We are speaking here not about stifness is absolute terms, but rather about stiffness-to-weight ratio. I mean one should try to build the arm as stiff as possible for the given weight (rather light). The stiffer the arm, the higher its natural resonant frequency is. And higher frequencies can be damped much more easily.

Feel free to contact me if you are interested, when you are back to Israel.

- Status

- Not open for further replies.