When drilling and tapping in copper use Oil of Wintergreen as the lubricant.

As a Jeweller working in silver, gold and occasionally copper this is standard practice.

bob

As a Jeweller working in silver, gold and occasionally copper this is standard practice.

bob

YouTubeCopper is always difficult. It tends to be very gummy. It's a bit like brass, only much worse. Drills tend to grab, and tapping is no fun.

Never had an issue (manually) tapping copper though.

Last edited:

I don’t plan on tapping copper again anytime soon. I use “Tap Magic” on all my drill and tap operations now. Will try wintergreen oil though - smells too good to put on a drill bit.

Just struck me that this is the amp for the House of Greyjoy. Ironborn. Big Iron amp.

I just cranked it up to 100w on my TL speakers. Still sounded clean - party levels loud!

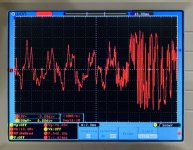

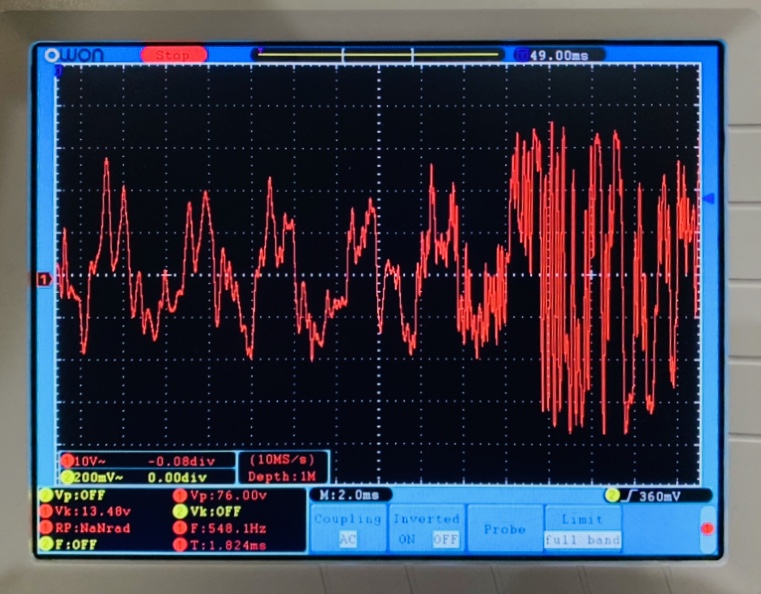

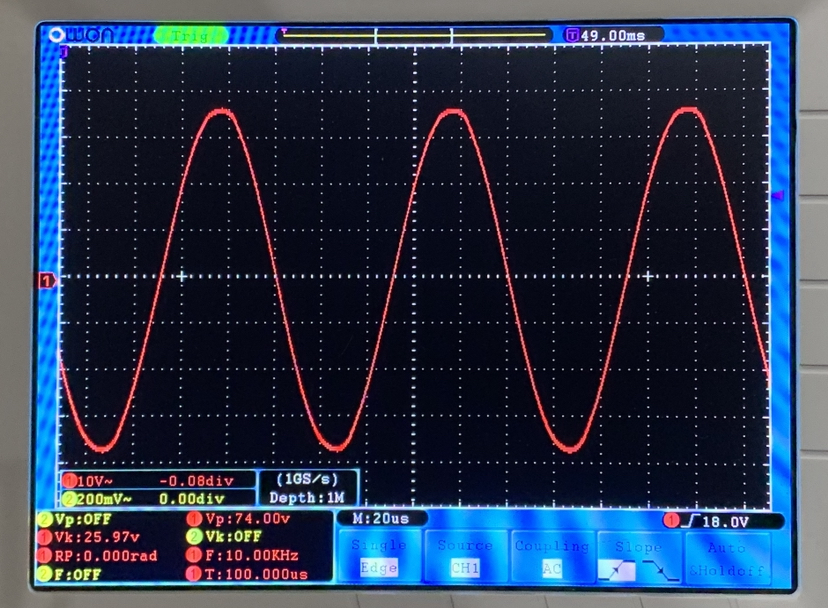

Some electronic dance music here at 76Vpp, no clipping to be seen yet.

I just cranked it up to 100w on my TL speakers. Still sounded clean - party levels loud!

Some electronic dance music here at 76Vpp, no clipping to be seen yet.

Attachments

Last edited:

This build and thread is satisfying on many levels.

I appreciate the metal work insights as much as the unique heat sink options.

Griddles and wintergreen?!

(I would go for cheap aluminum options rather than cast iron, in order to be able to drive the devices harder. Also, are 50 Volt caps good enough for 45 Volt rails?)

I appreciate the metal work insights as much as the unique heat sink options.

Griddles and wintergreen?!

(I would go for cheap aluminum options rather than cast iron, in order to be able to drive the devices harder. Also, are 50 Volt caps good enough for 45 Volt rails?)

So using it for cooking might not be the healthiest idea, but looks good for a heatsink!

As a side note, some microprocessors (Intel is terrible about this) have heat spreaders that are pretty far from being flat. One of my friends couldn't figure out why his overclocked CPU was overheating even with a water cooler, until I checked it against a surface plate and demonstrated that the high spot was high by nearly a millimetre. Lapping the top of the heat-spreader improved things by almost 35 C. I've seen similar things with transistors as well.

A simple technique for flattening is to put a sheet of fine abrasive paper on a flat glass plate and rub the part in question around on this nominally flat surface, holding the abrasive firmly in place on the glass.

If you find some glass object which makes good undistorted reflections its likely to be pretty flat and useful for this, so long as its not too thin and bendy under load.

This would likely create a slightly convex surface on the part, which is definitely preferable to the concave surface that often comes from the factory and sometimes even preferred to a perfectly flat surface (e.g. for heatsink contact)A simple technique for flattening is to put a sheet of fine abrasive paper on a flat glass plate and rub the part in question around on this nominally flat surface, holding the abrasive firmly in place on the glass.

Yes, a lapping plate. My experience with the backs of TO-247 or TO-264 MOSFETs or transistors from a reputable source is that they are quite flat. My cast iron is definitely not flat and perhaps use of a small hardened steel machinists block with a sheet of sandpaper wrapped over it would work to make small flat where the transistor mounts. However, it seems that use of thermal compound and 1mm thick alumina insulator pads has worked well for me on the Griddle Amp. The MOSFET bodies never measure more than 37C even playing loudly. For lower power (under 200w) Class AB, I think cast iron plates like this are a fine heatsink. I think the silicone sheets do not work as well and may be problematic if there is a sharp burr in the cast iron that can puncture the silicone and cause a short.

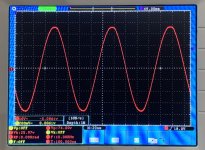

With a 300VA 32v trafo, I was able to get 74vpp into a benign 10ohm resistive load for 68w continuous. The voltage rails sagged to 38v under full power before clipping. Looks like you need a 40v traffo to hit the solid 100w+ continuous load.

Attachments

You mean spring clips to hold the MOSFETs to the heatsink? You still need to attach the clip to the sink with a rivet? Drilling is still required.

For one of the MOSFETs, a screw is still required since the Vbe multiplier temp sensor is mounted on top.

It seemed that tapping was an issue, figured the spring would take that away.

Also hadn’t seen any mention of properly torquing, and that would again take that requirement off the table.

I have had the Griddle Amp on continuously for a week now. Listening to it all day everyday. What a great amp and it still looks cool. Runs a at 32C in average. Pretty cool.

Another month in and the griddle amp is running strong and still the main amp in my system. Cast iron griddles make excellent Class AB amp heatsinks. Just a reminder that folks should give it a try. Certainly less expensive than $80 heatsink profiles or $250 chassis from typical amp chassis suppliers.

Hi X,

The solution is certainly appealing however I see 2 problems:

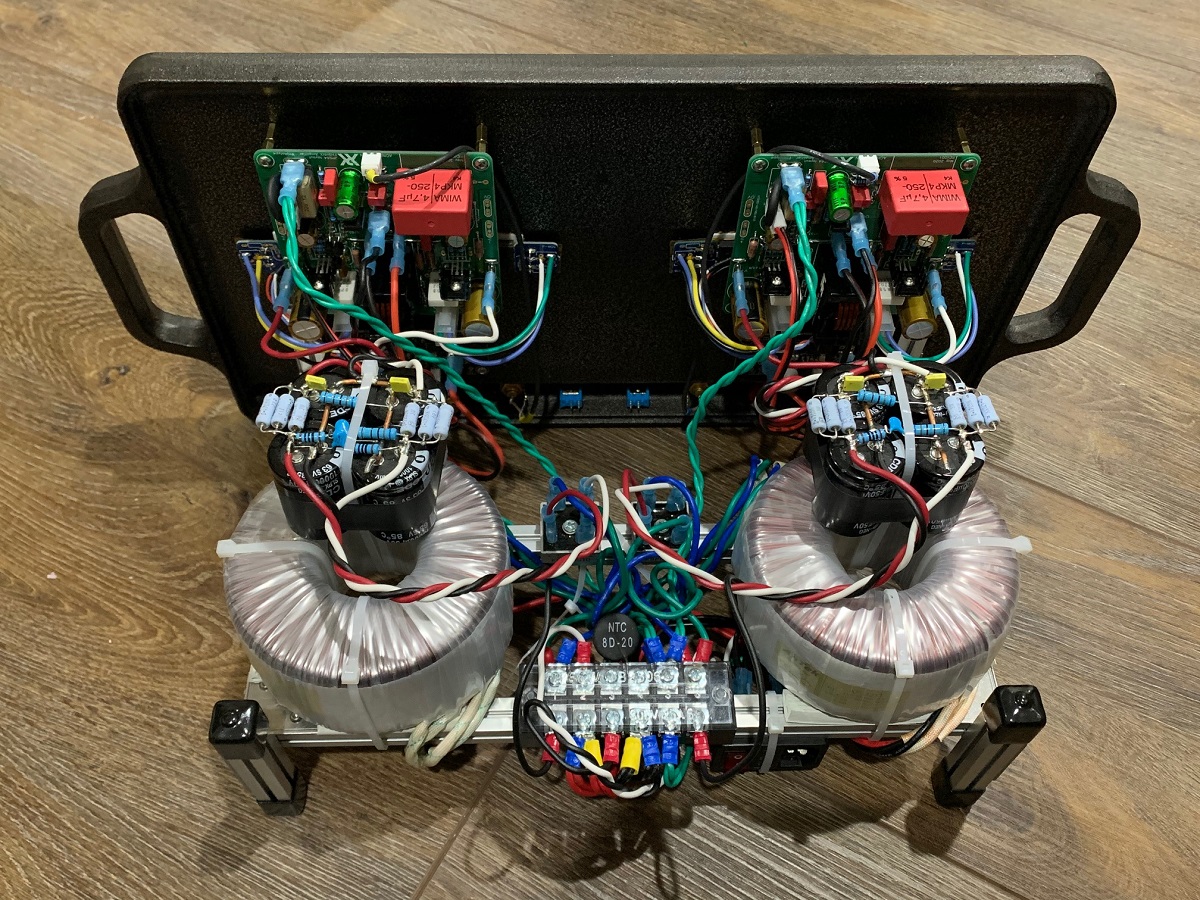

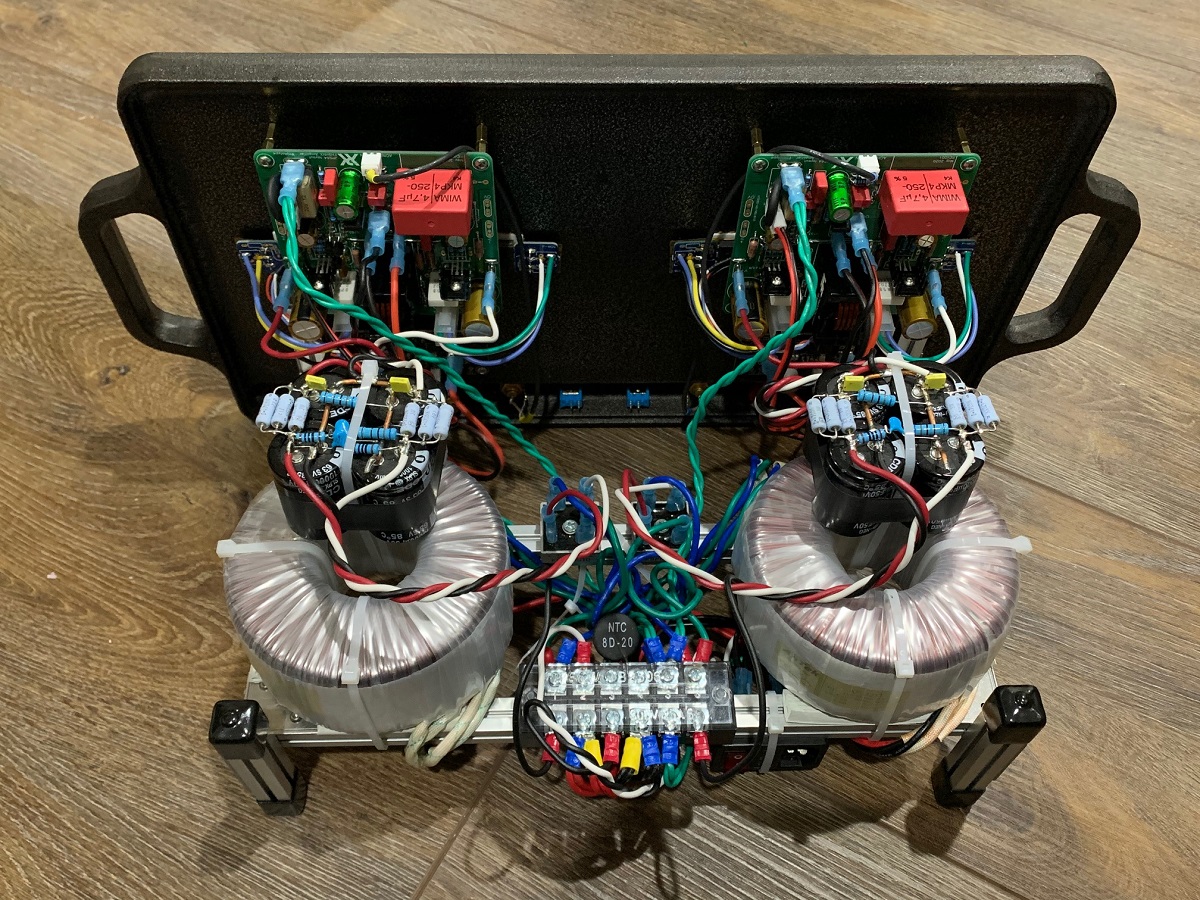

- DC leads are exposed (top of electrolytics) with a ~70-80V differential, not deadly for a grownup but extremely unpleasant (I tried!), experiences with kids might vary...

- negative WAF (for those living in couple).

Cheers,

Jacques

The solution is certainly appealing however I see 2 problems:

- DC leads are exposed (top of electrolytics) with a ~70-80V differential, not deadly for a grownup but extremely unpleasant (I tried!), experiences with kids might vary...

- negative WAF (for those living in couple).

Cheers,

Jacques

A simple cover can be made from the MakerBeam and 3mm thick wood or polycarbonate or acrylic panels.

For example:

Polycarbonate (Lexan) sheet TRANSPARENT (1p) - MakerBeam

For safety a bent U shaped perforated sheet metal stock.

Can’t help you with WAF. Mine is in my lab.

For example:

Polycarbonate (Lexan) sheet TRANSPARENT (1p) - MakerBeam

For safety a bent U shaped perforated sheet metal stock.

Can’t help you with WAF. Mine is in my lab.

Hi X,

The solution is certainly appealing however I see 2 problems:

- DC leads are exposed (top of electrolytics) with a ~70-80V differential, not deadly for a grownup but extremely unpleasant (I tried!), experiences with kids might vary...

- negative WAF (for those living in couple).

Cheers,

Jacques

I just gave this amp to my good friend as a present and his wife loves it!

At least WAF was not an issue there. They don’t have any little kids so no problem.

- Home

- Amplifiers

- Solid State

- The Cast Iron Griddle Amp - a Budget Conscious Heatsink Solution