Joe, I am as interested as you in better sound. And I think your impedance ideas are important. Anything to give an amplifier a softer ride. Because phase angles are indicative of stored energy, which is always an enemy.

Audio design is generally very slack. Professionals do it differently.

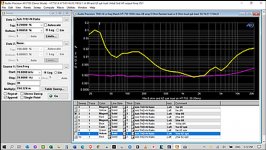

This is the proper way to eliminate noise on Earth Rails aka Common mode distortion:

Too expensive for most Audio use. But an Earth is just a reference point, it is not a fixed voltage. All this harmonic distortion measurement is very hard to make sense of. Symmetrical clipping produces odd harmonics, and IIRC the sort of Asymmetrical distortion from single rail power supplies produces even harmonics.

We used to do a different sort of distortion measurement at HF. Called White Noise Testing. Idea is you fire narrow band white noise at a system, and measure the white noise intermodulated in adjacent channels. Think of it like a strong radio station leaking into weaker ones in adjacent channels.

Sine waves aren't the only game in town either. You can use impulses (clicks) and smooth Gaussian pulses too. All transform maths in the end.

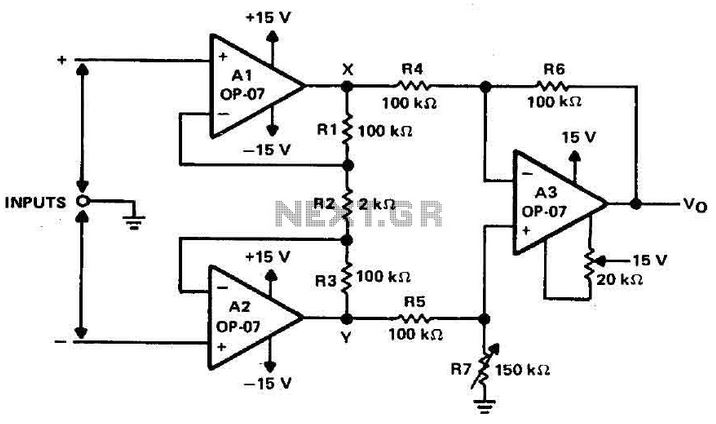

Here's a bit of fun. Height of the 1960's Valve age. All valve sound, eh? NO. It had a transistor at the Phono input. Worked beautifully! I had one.

Who knows? 😀

Audio design is generally very slack. Professionals do it differently.

This is the proper way to eliminate noise on Earth Rails aka Common mode distortion:

Too expensive for most Audio use. But an Earth is just a reference point, it is not a fixed voltage. All this harmonic distortion measurement is very hard to make sense of. Symmetrical clipping produces odd harmonics, and IIRC the sort of Asymmetrical distortion from single rail power supplies produces even harmonics.

We used to do a different sort of distortion measurement at HF. Called White Noise Testing. Idea is you fire narrow band white noise at a system, and measure the white noise intermodulated in adjacent channels. Think of it like a strong radio station leaking into weaker ones in adjacent channels.

Sine waves aren't the only game in town either. You can use impulses (clicks) and smooth Gaussian pulses too. All transform maths in the end.

Here's a bit of fun. Height of the 1960's Valve age. All valve sound, eh? NO. It had a transistor at the Phono input. Worked beautifully! I had one.

Who knows? 😀

we often hear people tell us no one can hear distortion as low as spec'ed and as low as measured. But thats always with resistive loads. What about real speakers as a load? Your speakers? Shown is a commercially available 2-way book shelf speaker at 5W signal. All amps seem to show higher distortion when measured with real speakers for a load.

Maybe people do hear amp distortion?

The shape of the "distortion" or extraneous signal/noise or what ever you like to call it, follows the Z of the speaker. So, every amp will "sound different" with different loads.

-C31697

Maybe people do hear amp distortion?

The shape of the "distortion" or extraneous signal/noise or what ever you like to call it, follows the Z of the speaker. So, every amp will "sound different" with different loads.

-C31697

Curious first posts for a new member. You attached a thumbnail BTW so we can't see your graph.

...we can't see your graph.

Not very good, but maybe a little better...

Attachments

I really can't read the scale, but higher distortion towards lower freq with real speaker is not surprising, knowing that speaker impedance in that region is much less than 8 ohms.

What the xover filter does upwards is anybody's guess.

Jan

What the xover filter does upwards is anybody's guess.

Jan

Nonlinear load vs. finite output impedance (divider effect), the explanation is trivial.

At acoustical side it is even more trivial.

At acoustical side it is even more trivial.

You post just like someone who is already a member here.we often hear people tell us no one can hear distortion as low as spec'ed and as low as measured. But thats always with resistive loads. What about real speakers as a load? Your speakers? Shown is a commercially available 2-way book shelf speaker at 5W signal. All amps seem to show higher distortion when measured with real speakers for a load.

Maybe people do hear amp distortion?

Before commenting on the distortion what is the output impedance of the amp? The Series impedance of the amp will transform the speakers nonlinear load into voltage distortion. Otherwise the distortion is only in the current waveform. I'm not sure what this tells us about the acoustic distortion differences, both linear and nonlinear.

Former resident of Cool, California?

Someone who is a fan of magenta at least....

Howie

Nonlinear load vs. finite output impedance (divider effect), the explanation is trivial.

At acoustical side it is even more trivial.

Before commenting on the distortion what is the output impedance of the amp? The Series impedance of the amp will transform the speakers nonlinear load into voltage distortion. Otherwise the distortion is only in the current waveform.

Exactly right.

Stein

Totally off the audio subject, I am rebuilding a WWII machine tool. A Brown and Sharpe #2B surface grinder. Surprisingly the main spindle bearings are not worn out. The ways did require a few hours of scraping to become flat according to “High Spot Blue” and my precision ground straight edge.

Removing the prior owner’s latex paint took a few days. The amount of just dirt removed should take a few pounds off its’ weight of 1400 pounds! Just a bit of repainting to do.

All the mechanics seem to be restored and working.

Next week it is the motor. Size of the motor is consistent with a modern 100 HP unit, but it is only 1.5 HP! Nameplate says it can run on 3 phase 220 or 440 VAC 50 or 60 Hz. I have 208/60 available. Fortunately as my power is shared with residences that want to see 220 single phase, my 208 is really around 216, so I do not expect problems.

Biggest issue has been coming home a bit dirty with 80 years of grease and dirt!

Big secret... the best way to clean things like this is spray oven cleaner.

When up and running it should be able to hold tolerances of .0001”.

New Chinese not really good copies run $3,000.00 and I bought two way used ones for $150.00 plus a week of work. I did have to buy a new grinding wheel for $30.00, paint ran about the same. Biggest expense will be a few new clothes! 😉

This unit is used to sharpen tools for my turret punch.

Best part is the incredibly dirty work is finished. Downside is after so much work I am beginning to notice arthritis in my hands.

Removing the prior owner’s latex paint took a few days. The amount of just dirt removed should take a few pounds off its’ weight of 1400 pounds! Just a bit of repainting to do.

All the mechanics seem to be restored and working.

Next week it is the motor. Size of the motor is consistent with a modern 100 HP unit, but it is only 1.5 HP! Nameplate says it can run on 3 phase 220 or 440 VAC 50 or 60 Hz. I have 208/60 available. Fortunately as my power is shared with residences that want to see 220 single phase, my 208 is really around 216, so I do not expect problems.

Biggest issue has been coming home a bit dirty with 80 years of grease and dirt!

Big secret... the best way to clean things like this is spray oven cleaner.

When up and running it should be able to hold tolerances of .0001”.

New Chinese not really good copies run $3,000.00 and I bought two way used ones for $150.00 plus a week of work. I did have to buy a new grinding wheel for $30.00, paint ran about the same. Biggest expense will be a few new clothes! 😉

This unit is used to sharpen tools for my turret punch.

Best part is the incredibly dirty work is finished. Downside is after so much work I am beginning to notice arthritis in my hands.

Last edited:

Wow, that's a great story, Ed. Congratulations!

My pops always felt the best way to clean ANYTHING was WD-40 + brass bristle brush.

My pops always felt the best way to clean ANYTHING was WD-40 + brass bristle brush.

Coolant (soluble oil/water) and paraffin (dielectric) 50/50 mix was aBig secret... the best way to clean things like this is spray oven cleaner.

surprisingly good way of cleaning machine tools when I was an apprentice toolmaker in the 70's🙂

Mark,

For this project I am on my third brass bristle brush. BTW your dad was right. That is a good way for most tools. This case is a bit older, dirtier and more congealed than I would use with WD40 or coolant oil. Also the oven cleaner removes latex paint, but doesn’t affect the lead based battleship gray paint.

After the flood from hurricane Ivan, I was buying a case of WD40 when a guy watching me, asked if it was at a good price! My facial expression gave him a hint I thought he might be stupid. (Do you have any idea what your clothes and general appearance look like cleaning up from a flood? Hint the flood waters clean all the mud out of the sewers.)

For this project I am on my third brass bristle brush. BTW your dad was right. That is a good way for most tools. This case is a bit older, dirtier and more congealed than I would use with WD40 or coolant oil. Also the oven cleaner removes latex paint, but doesn’t affect the lead based battleship gray paint.

After the flood from hurricane Ivan, I was buying a case of WD40 when a guy watching me, asked if it was at a good price! My facial expression gave him a hint I thought he might be stupid. (Do you have any idea what your clothes and general appearance look like cleaning up from a flood? Hint the flood waters clean all the mud out of the sewers.)

Last edited:

There is no substitute for massive cast iron on a machine tool. Although concrete comes close. And at the age of the machine it should be really stable.

Ultimate knife sharpener.

Maybe the bigger motor frame helps reduce motor vibration. 208 vs 220 should not make a difference. And make sure you have the proper low voltage protection or you could fry the motor.

Ultimate knife sharpener.

Maybe the bigger motor frame helps reduce motor vibration. 208 vs 220 should not make a difference. And make sure you have the proper low voltage protection or you could fry the motor.

Totally off the audio subject, I am rebuilding a WWII machine tool. A Brown and Sharpe #2B surface grinder. Surprisingly the main spindle bearings are not worn out. The ways did require a few hours of scraping to become flat according to “High Spot Blue” and my precision ground straight edge.

Removing the prior owner’s latex paint took a few days. The amount of just dirt removed should take a few pounds off its’ weight of 1400 pounds! Just a bit of repainting to do.

All the mechanics seem to be restored and working.

Next week it is the motor. Size of the motor is consistent with a modern 100 HP unit, but it is only 1.5 HP! Nameplate says it can run on 3 phase 220 or 440 VAC 50 or 60 Hz. I have 208/60 available. Fortunately as my power is shared with residences that want to see 220 single phase, my 208 is really around 216, so I do not expect problems.

Biggest issue has been coming home a bit dirty with 80 years of grease and dirt!

Big secret... the best way to clean things like this is spray oven cleaner.

When up and running it should be able to hold tolerances of .0001”.

New Chinese not really good copies run $3,000.00 and I bought two way used ones for $150.00 plus a week of work. I did have to buy a new grinding wheel for $30.00, paint ran about the same. Biggest expense will be a few new clothes! 😉

This unit is used to sharpen tools for my turret punch.

Best part is the incredibly dirty work is finished. Downside is after so much work I am beginning to notice arthritis in my hands.

Sounds like a nice job, post some pics when you are finished.

I don't recall using a B & S, probably did but certainly many Jones &

Shipmans (more common down here) which were also really good grinders.

TCD

- Home

- Member Areas

- The Lounge

- The Black Hole......