Good day all,

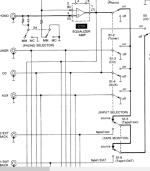

I need some advice please. I have a Technics su-v550 and the record switch flexible flat cable that goes to the switch on the pcb is broken. I want to replace the switch and cable with a rotary switch. Will a 4 gang/ 6 contact per gang rotary switch do the job ?

Advice appreciated.

Regards

Jan

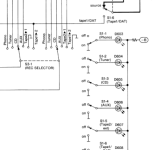

Guy's, here is a better layout of the original switch, which rotary switch will work, is a 4 gang up to the task ?

Thanks

I need some advice please. I have a Technics su-v550 and the record switch flexible flat cable that goes to the switch on the pcb is broken. I want to replace the switch and cable with a rotary switch. Will a 4 gang/ 6 contact per gang rotary switch do the job ?

Advice appreciated.

Regards

Jan

Guy's, here is a better layout of the original switch, which rotary switch will work, is a 4 gang up to the task ?

Thanks

Attachments

Last edited:

Guy's, this is the first time that I work with rotary switches, will this one work ?

C4D0406N-A from mouser.

Regards

Jan

C4D0406N-A from mouser.

Regards

Jan

madis64,

This is the link to the datasheet.

https://www.mouser.co.za/ProductDetail/Electroswitch/C4D0406N-A?qs=J%2BLxE1TJwwVZoZYHyHhgNQ==

This is the link to the datasheet.

https://www.mouser.co.za/ProductDetail/Electroswitch/C4D0406N-A?qs=J%2BLxE1TJwwVZoZYHyHhgNQ==

I meant your device, your cable and your switch 🙂This is the link to the datasheet.

Khm, I see just 4 screenshots of schematics, no photos of actual gear.The last photo is the best.

Oh, the switch is a manual rotary selector working the actual switch via a flexible cable. the end of the cable latches on to the manual switch. I am going to replace this cable and install a rotary switch with wires running to the original switch position.

Ok, now I understand - the switch has a rotary actuator on the front panel and the steel belt connecting the actuator and sliding switch is broken?

If so then how is it broken? I.e. can it not be repaired?

Also such switches are common in some older amplifiers - perhaps purchasing one in defect state as a spare part donor would solve the problem without pulling the signal cables from the rear to the front panel (and back)?

If so then how is it broken? I.e. can it not be repaired?

Also such switches are common in some older amplifiers - perhaps purchasing one in defect state as a spare part donor would solve the problem without pulling the signal cables from the rear to the front panel (and back)?

In South Africa, possible but not probable, I have shortened the steel belt and drilled 0.8mm holes with a Dremel to fix it to cath on the cogh ,but it seems that the belt is worn. Somebody else has tried to fix it before and has caused problems, that why I am reverting to a separate hard wired rotary switch.😉

Sorry but without a photo it is difficult to grasp how such a set would "wear out" on the belt side.I have shortened the steel belt and drilled 0.8mm holes with a Dremel to fix it to cath on the cogh ,but it seems that the belt is worn.

But ok, if you say it cannot be repaired then it cannot be repaired - I would then use a relay based input selector from eBay to keep the signal communications near the rear panel.

For other forum members, most probably the problem is with switches like these (located near back panel, operated by actuators on the front panel):

If you use that switch then the selector knob positions will not match the labels on front panel?This is the link to the datasheet.

Madis64, Why do you say that switch will not correspond with the markings on the face plate or do I miss something.🤔

There is another switch but I don't see the difference. Must be D-shaft, 6 positions, 4 banks and 30deg switching, they look the same.

https://www.mouser.co.za/ProductDetail/Electroswitch/C4D0406S-A?qs=lwrXE7cXt4TwpQEUJIHtwg==

OK, I see the difference, one is shorting and the other non shorting contacts, but the datasheet shows 30 deg index.

There is another switch but I don't see the difference. Must be D-shaft, 6 positions, 4 banks and 30deg switching, they look the same.

https://www.mouser.co.za/ProductDetail/Electroswitch/C4D0406S-A?qs=lwrXE7cXt4TwpQEUJIHtwg==

OK, I see the difference, one is shorting and the other non shorting contacts, but the datasheet shows 30 deg index.

Last edited:

I am not "saying" that, I am just being doubtful (better safe than sorry) 🙂Why do you say that switch will not correspond with the markings on the face plate

The rotary switch should also have some sort of limiter to prevent it from being rotated into positions exceeding the labelled area on panel.

You would not post photos of the failed belt/strip assembly?

And is the record selector functionality actually needed? If not then I would just fix the switch in some position with a drop of silicone or some glue.

Last edited:

I have drilled 6 holes in the belt for the cog to catch on but I still need a ball bearing for a small pressure plate to put pressure on the belt not to slip. The whole unit might be too short now, if it is working. So I'm just looking for an alternative so long. 😉

Attachments

- Home

- Amplifiers

- Solid State

- Technics SU-V550