why would you want a higher loss? or is that the panel's reverse output below the drivers output?

Like:

The driver puts out 100 db, at -25db from panel, meaning 75db output heard?

or the panels output 75db of negative wave?

or 25db of opposite signal?

Like:

The driver puts out 100 db, at -25db from panel, meaning 75db output heard?

or the panels output 75db of negative wave?

or 25db of opposite signal?

I'll clarify

Noah means when the driver's output is 100db then the panels' output is 75db. The panel output is 25db lower thus -25db relative to the driver.

Noah means when the driver's output is 100db then the panels' output is 75db. The panel output is 25db lower thus -25db relative to the driver.

I've been concerned by some of the things people have said that I'm not planning enough bracing. But that's a size I would have never considered to do w/o bracing, so now maybe I'm not so far off.noah katz said:A few months ago I did FEA (finite element analysis) of a 16 cu ft sealed box made from 3/4" plywood, for a pair of Avalanche 18 drivers. ... I was hoping to satisfy myself that an unbraced box would be fine.

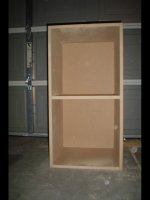

I'll just cut to the chase. 🙂 I'm building a box that is a tall slender column: about 15" square by about 36" high, which will contain two 12" drivers, but it will be separated into two separate chambers. So essentially, I'm looking at two 2.1 cu ft boxes with a 12" driver each. But the divider panel in the middle of the column will be arranged at an angle, so the largest panel in each section will be about 25" x 15". All other panels will be smaller than that. So how much bracing would people suggest? Based on the previous recommendation of 6-12" between braces, the 25" panel would need two braces. To me, that seems like overkill for this small of a box.

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Subwoofers

- Sub project-construction technique questions