As a semi-offshoot of this thread, I did some quick testing on using stuffed "TL" tubes for drivers meant to be high-passed above a midbass.

Test mule was FF85WK, a rather likely suspect for such an application. I first decided to test it's free-air T/S parameters in LIMP. Here is the result for one driver only:

Loudspeaker parameters:

Fs = 115.89 Hz

Re = 7.50 ohms[dc]

Le = 154.52 uH

L2 = 144.24 uH

R2 = 4.41 ohms

Qt = 0.60

Qes = 0.68

Qms = 5.10

Mms = 1.98 grams

Rms = 0.292124 kg/s

Cms = 0.000946 m/N

Vas = 1.04 liters

Sd= 27.99 cm^2

Bl = 4.063108 Tm

ETA = 0.24 %

Lp(2.83V/1m) = 86.16 dB

Added Mass Method:

Added mass = 10.00 grams

Diameter= 5.97 cm

Holy crap! How close this is to factory data! 😱 Qms is a tad higher but most of the rest is quite close. Feels satisfying to get these kinds of results once in a while. 🙂

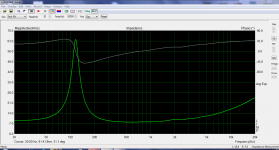

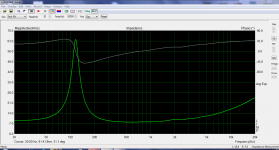

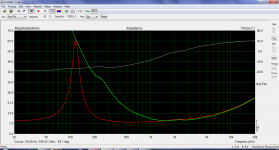

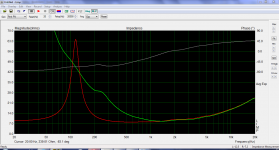

For a tube, I had some unused Precision Port mid-secions laying around. 3" internal diameter, 12" long. Fits right over the plastic bezel on FF85WK, with a bit of blu-tak to seal things up good. Here's the empty tube:

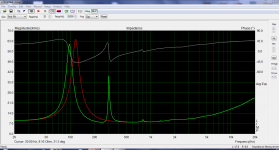

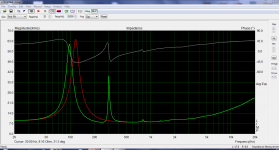

Tunes about where it should. Let's try a bit of polyfill in there, loosely packed in most of the length:

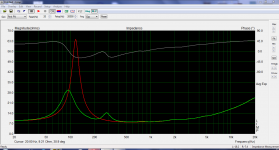

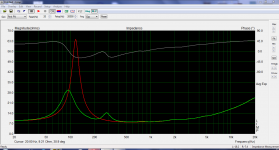

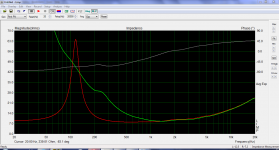

Now let's pack it real good in there: 🙂

Good improvement! On my first try, I had flatter Z and some fuzz on the trace. I figured the polyfill tried to expand and mechanically hindered cone motion. I packed the same amount (24g) of polyfill into a wool sock and could now control the depth to avoid the issue.

Perhaps a 3" tube is a bit small to load on the back of FF85WK in a real application, it would not even leave room for a good chamfer. It's what I had handy and still learned something from it. Hope it can be of use to others, so I'm sharing this here. 12" is also a bit long for my application at least, so a tapper would help as suggested by P10, or perhaps even a bit of mass-loading on a shorter straight tube?

Test mule was FF85WK, a rather likely suspect for such an application. I first decided to test it's free-air T/S parameters in LIMP. Here is the result for one driver only:

Loudspeaker parameters:

Fs = 115.89 Hz

Re = 7.50 ohms[dc]

Le = 154.52 uH

L2 = 144.24 uH

R2 = 4.41 ohms

Qt = 0.60

Qes = 0.68

Qms = 5.10

Mms = 1.98 grams

Rms = 0.292124 kg/s

Cms = 0.000946 m/N

Vas = 1.04 liters

Sd= 27.99 cm^2

Bl = 4.063108 Tm

ETA = 0.24 %

Lp(2.83V/1m) = 86.16 dB

Added Mass Method:

Added mass = 10.00 grams

Diameter= 5.97 cm

Holy crap! How close this is to factory data! 😱 Qms is a tad higher but most of the rest is quite close. Feels satisfying to get these kinds of results once in a while. 🙂

For a tube, I had some unused Precision Port mid-secions laying around. 3" internal diameter, 12" long. Fits right over the plastic bezel on FF85WK, with a bit of blu-tak to seal things up good. Here's the empty tube:

Tunes about where it should. Let's try a bit of polyfill in there, loosely packed in most of the length:

Now let's pack it real good in there: 🙂

Good improvement! On my first try, I had flatter Z and some fuzz on the trace. I figured the polyfill tried to expand and mechanically hindered cone motion. I packed the same amount (24g) of polyfill into a wool sock and could now control the depth to avoid the issue.

Perhaps a 3" tube is a bit small to load on the back of FF85WK in a real application, it would not even leave room for a good chamfer. It's what I had handy and still learned something from it. Hope it can be of use to others, so I'm sharing this here. 12" is also a bit long for my application at least, so a tapper would help as suggested by P10, or perhaps even a bit of mass-loading on a shorter straight tube?

Last edited:

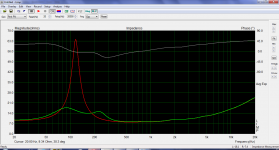

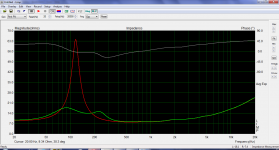

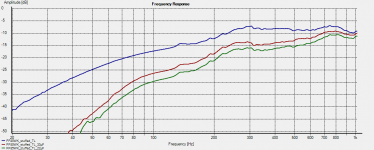

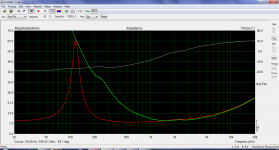

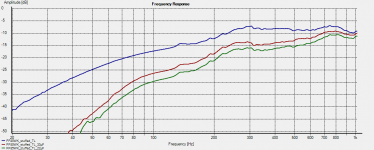

Impedance with stuffed TL, 24g of polyfill and...

22µF series capacitor:

33µF series capacitor:

Resulting near-cone response (back of the cone):

Blue: no Xover

Red: 33µF capacitor

Green: 22µF capacitor

There still appears to be a tad of interaction with the impedance peak above 200Hz, but nothing seemingly too serious.

22µF series capacitor:

33µF series capacitor:

Resulting near-cone response (back of the cone):

Blue: no Xover

Red: 33µF capacitor

Green: 22µF capacitor

There still appears to be a tad of interaction with the impedance peak above 200Hz, but nothing seemingly too serious.

Regarding the first post's plots for "naked tube" --> "light stuffing" --> "heavy stuffing", we can see that, in addition to damping of the impedance, the tuning minima shifts down respectively from ~250Hz to ~200Hz to ~175Hz. Would this be the supposed, effective "slowing down" of the the speed of sound in a resistive material?

Correct, though it's my understanding that it doesn't slow down, it just takes more time to traverse the pipe since the stuffing makes it acoustically longer. Overall, it looks like the pipe is still much too short percentage wise and depending on the performance goals, anywhere from not small enough to nearly an order of magnitude too small a net Vb.

GM

GM

I'd like to test on some 4" I.D. tubing to compare, possibly sealed/aperiodic as well. Something with a taper as mentioned before too, as I can't have much more than 8" of cabinet depth. It'll be about integration in the end.

Last edited:

Good IG81. Here is the impedance we gotwith Tysen (FF85k in short 10:1 line)

dave

I caught that one in the Tysen thread. Looks like I got ~ballpark tuning and Z magnitude with my stuffed straight line.

I'd like to test on some 4" I.D. tubing to compare

In theory, 6" would be better if it's available at reasonable prices like down here.

GM

In theory, 6" would be better if it's available at reasonable prices like down here.

GM

Mmm, not certain I see how, at least Hornresp is showing me smaller magnitude Z peaks in 3" versus 4" ang 6", for equal length and comparable stuffing density, unless I messed up that last part. 🙂

For TL max acoustic efficiency after damping [max gain BW] requires at least a 4x Vas net Vb, ergo will have the highest impedance peaks whereas a < half Vas net Vb results in max acoustic damping [narrowest gain BW], ergo lowest impedance peaks; so if your goal is max acoustic damping to minimize stuffing, drop down to a 1.5" pipe with cone adapter like the B0$3 wave cannon uses.

GM

GM

I suppose if you wanted to get fancy, Dave's idea of a simple short reverse taper TL partition could be expanded into a simple one fold TL. Just add a horizontal partition, and crop the slanted board so it's an internal divider with the opening at the small end. I'm not sure if it'd be worth the effort, but it would drive the TL tuning frequency down by ~ half.

If you wanted to get really fancy, how about take that 6" pipe, and roll a laminated paper funnel/cone, mount it concentrically, and use the small end for the exit. That would make a nice conical reverse taper pipe twice the depth of the cabinet.

I suppose if you wanted to get fancy, Dave's idea of a simple short reverse taper TL partition could be expanded into a simple one fold TL. Just add a horizontal partition, and crop the slanted board so it's an internal divider with the opening at the small end. I'm not sure if it'd be worth the effort, but it would drive the TL tuning frequency down by ~ half.

The midTL is not something i came up with myself, the implementations that inspired me were rectangular boxes with a partition to make them into a tapered line (with terminus at the front)

dave

Yeah, I did think about making a horizontal bend in a ~square CSA enclosure with a front terminus.

Ultimately, I think I may only build a simple box for my midbass, to allow swapping horns/WG's on top with closer ctc spacing, including the possibility for a non length-limited damped straight tube for a fullrange driver. 🙂 I like to keep things flexible when just wanting to toy with various concepts.

GB, the internal cone things sounds pretty cool to keep things shorter externally if needed.

Ultimately, I think I may only build a simple box for my midbass, to allow swapping horns/WG's on top with closer ctc spacing, including the possibility for a non length-limited damped straight tube for a fullrange driver. 🙂 I like to keep things flexible when just wanting to toy with various concepts.

GB, the internal cone things sounds pretty cool to keep things shorter externally if needed.

wd a closed line work even better for flattening the impedance?

Trying this in Hornresp, for the same diameter pipe and optimized stuffing density, even a 2x longer closed-end pipe does not seem like it'd work as well. It's not orders of magnitude apart, but the stuffed open line will be shorter and work better anyway. I suppose a low Qms driver with low-magnitude free-air impedance peaks might get away in a not-too-long stuffed closed pipe. I only see this useful if the pipe has to terminate inside the woofer enclosure for some reason.

Yeah, a closed pipe is a 1/2 WL resonator, so must be 2x long acoustically, though due to this increased length can damp a driver 'flat as a billiard table' with much less stuffing density, though ~ the same net bulk, i.e. compression horn damping, but with not only no gain, but lost efficiency referenced to an IB.

Whether it's worth it just depends on what your performance goals are.

GM

Whether it's worth it just depends on what your performance goals are.

GM

I'm wanting to use the TB W3-1878 in a 1st order design but the issue with it is the rather large impedance spike - so this looks to be the way to go

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Full Range

- Stuffed midrange TL for high-passed FR drivers