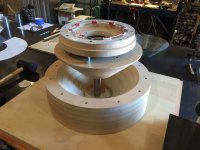

So I'm ready for the powder coater and I wanted to do a 2016 re-visit of the coatings discussion. I have experimented with the sprayon insulating varnish 609 green Insulating Varnish but the stuff is just a little to toxic for my home prototyping shop, I also don't want green stators and the guys at spray-on said that I should not top coat the 609. I'm not set up for any real HVLP spray work, so my thought was to have an epoxy powder coat done follow by a clear powder coat. I would love for anyone who had their "working great" stators powder coated to weigh in since most of the discussions have been around diy coatings. Based on industrial applications the epoxy seems to be a good choice, and I'm wondering if the brittleness of the epoxy has been the problem that others have had with failure... will any flex crack it or is there some wiggle room. I'm estimating these stators will be taking around 3k volts. Thanks for any advice... and yes these are conical which requires a very elaborate stretching press.

Attachments

Hi,

coat a non-filled nylon powder coating (white stuff) as thick as possible ... to be precise the first layer will be the nylon-primer of course.

Nylon (PA-6 and PA-66) features a nice set of the parameters dielectric constant, volume resistance, creep resistance, minimum radius for constant thickness and mechanical robustness.

You can then add a first thin wet sprayed layer with the color of Your choice.

Add 2-3 layers of clear top coating (high-gloss prefferrably) from a PU or a acrylic laquer .... ask Your coater which one bonds better with the colored layer and gives a pinhole-free surface.

I personally prefer solvent-based PU boat or staircase laquer due to their very smooth and very tough surface.

Don't forget to test the stator on flashovers

jauu

Calvin

coat a non-filled nylon powder coating (white stuff) as thick as possible ... to be precise the first layer will be the nylon-primer of course.

Nylon (PA-6 and PA-66) features a nice set of the parameters dielectric constant, volume resistance, creep resistance, minimum radius for constant thickness and mechanical robustness.

You can then add a first thin wet sprayed layer with the color of Your choice.

Add 2-3 layers of clear top coating (high-gloss prefferrably) from a PU or a acrylic laquer .... ask Your coater which one bonds better with the colored layer and gives a pinhole-free surface.

I personally prefer solvent-based PU boat or staircase laquer due to their very smooth and very tough surface.

Don't forget to test the stator on flashovers

jauu

Calvin

Thanks Calvin.

Is the PU a better dialectic than the Acrylic? I have a case of Permalac and few cans of Deft Gloss clear that are both Acrylic lacquers I use on a regular basis, but if the Poly is better I will add some to my collection. Will rattle-can coats will be OK, or should it really be sprayed thru a gun?

Is the PU a better dialectic than the Acrylic? I have a case of Permalac and few cans of Deft Gloss clear that are both Acrylic lacquers I use on a regular basis, but if the Poly is better I will add some to my collection. Will rattle-can coats will be OK, or should it really be sprayed thru a gun?

Hi,

the electrical important parameters of PU and Acrylics are very similar.

Axrylics have the advantage of coming in water-based, or water soluable-solutions which is less environmental stressing and less ´stinky´.

With regard to a perfect levelling clean surface solvent based laquers were the better choice, though the water-based laquers seem to have closed the gap.

My preference for solvent based PU is simply that I seem incapable of getting a perfect finish with Acrylic laquers, wether I paint, roll, gun-spray or can-spray ... I always get disaster.

But You and others may be perfectly confident with Acrylics.

For the end result its important, that the surface is perfectly flat and clean without pinholes and pickles.

A spray-gun process seems more suitable to reach that goal, but can-spray may be perfectly suitable for You.

I guess that besides the laquer consistency and the tools it all depends on Your talent as painter.

Besides, Your powdercoater will probabely be able to do wet-coating also.

I´d have him paint the stators in fullness.

jauu

Calvin

the electrical important parameters of PU and Acrylics are very similar.

Axrylics have the advantage of coming in water-based, or water soluable-solutions which is less environmental stressing and less ´stinky´.

With regard to a perfect levelling clean surface solvent based laquers were the better choice, though the water-based laquers seem to have closed the gap.

My preference for solvent based PU is simply that I seem incapable of getting a perfect finish with Acrylic laquers, wether I paint, roll, gun-spray or can-spray ... I always get disaster.

But You and others may be perfectly confident with Acrylics.

For the end result its important, that the surface is perfectly flat and clean without pinholes and pickles.

A spray-gun process seems more suitable to reach that goal, but can-spray may be perfectly suitable for You.

I guess that besides the laquer consistency and the tools it all depends on Your talent as painter.

Besides, Your powdercoater will probabely be able to do wet-coating also.

I´d have him paint the stators in fullness.

jauu

Calvin

Yes conical... just slightly easier than impossible at this radius. The real trick has been in designing a stretching jig that doubles as a press, then balancing the vertical displacement of the stretch versus the radial, but I believe I'm in the home "stretch". I will be posting the whole build soon, hope to have a working prototype Jan 2017, and I'm sure this forum will be a valuable resource for all the bugs that arise.

Attachments

Was thoroughly unimpressed with my power coater. I guess the job was O.K. from a cosmetic standpoint, and I sure most guys who have their rims coated aren’t using digital calipers and looking at the finish with jeweler’s glasses, but for what I need the job was crap. The coating ranged from 5 to 8 mills thick at the edges with some spots toward the middle being so light that I could see flecks of the base metal coming though the various bubbles and surface cracks which were far more numerous under magnification that I would have thought they would be. So I am undertaking a day of Helmsmen polyurethane gloss coating. Three just wet coats about 10 minutes in between (it's a little cold today) then a quarter turn on the hanging rod and another 3 coats until I have a total of 12 coats total. Then I’m going to see how thick I managed to get it. On the upside the Helmsman spray nozzle on the rattle cans is quite good. I have done a lot of spay painting in my time and this is some of the best flow and coverage I have been able to get with a rattle can. I’m sure most of this has to do with what is spraying out, but it’s nice to be able to go thru a whole can without any sputtering or flow inconsistencies… so far anyway.

Attachments

Never tried that Andersonix... but if I got any kind of arc, wouldn't the vapors ignite? I think I might rather waste the $10 on an extra can than chance a fireball. Don't get me wrong, I love the idea, and It is difficult to get a laminar stream connection with a disused spray, but it does sound a crazy dangerous. Would it work with a water-base spray?

Last edited:

Ja, water-based would probably be safer. Or don't rub the spray can against the stators to make arc.

Hi,

before painting You might consider to give the stator a heat treatment.

If You bake it up to the melting point of the power You might achieve a better surface finish.

I don't know what the stance of the metal is (holes diameter and distance) but the coating surely looks too thin and the surface looks matte instead of glossy.

And why is it black?

jauu

Calvin

before painting You might consider to give the stator a heat treatment.

If You bake it up to the melting point of the power You might achieve a better surface finish.

I don't know what the stance of the metal is (holes diameter and distance) but the coating surely looks too thin and the surface looks matte instead of glossy.

And why is it black?

jauu

Calvin

Well, it's suppose to be a heavy coat of primer with a thin coat of black. I thought the matt would have a better tooth for the clear coat, and black because thats the final color I want. These shots were before the clear I did today, they are glossy now. They didn't listen to a thing I told them anyway. They thought it was ok to powder coat the connectors then scrape "most" of the coating off instead of just masking them like they said they would. I found out on Friday that a co-worker's father owns a coating company that does race cars and airplanes to supper high end specifications. They will be helping me out on the next batch. 12 coats of rattle can polyurethane and I didn't add nearly as much thickness as I had wanted, they look ok but I should have been a little more aggressive on the coats.

With the insulation having a greater chance of failure, I think I'm going to dumb down my power supply with a variable bias for this prototype. I like MR's design with the Emco G40 modules. I think it might be a good way to go even if I had a perfect coating... but that is probably for another thread

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Planars & Exotics

- Stator Coatings