Oops, here it comes:

Power(watts) Core area (square cm)

SU48a 26,5 2,19

SU48b 44,5 3,47

SU60a 75,4 3,50

SU60b 116 5,30

SU75a 188 5,63

SU75b 297 9,01

SU90a 370 7,99

SU90b 610 13,40

Source: Vacuumschmelze

Power(watts) Core area (square cm)

SU48a 26,5 2,19

SU48b 44,5 3,47

SU60a 75,4 3,50

SU60b 116 5,30

SU75a 188 5,63

SU75b 297 9,01

SU90a 370 7,99

SU90b 610 13,40

Source: Vacuumschmelze

P,

have you looked at Watts/VA per core area sqcm?

in the order you have listed them VA/sqcm

12.1

12.9

21.5

21.9

33.4

33.0

46.3

45.5

That is certainly not VA pro rata with core area.

Can you explain this anomaly?

have you looked at Watts/VA per core area sqcm?

in the order you have listed them VA/sqcm

12.1

12.9

21.5

21.9

33.4

33.0

46.3

45.5

That is certainly not VA pro rata with core area.

Can you explain this anomaly?

Andrew,

Apart from core area also core mass / magnetic path length have (minor) influence.

For the smaller SU48 core you see that the b version not quite manages the higher power relative to the a version; here core mass is more important.

As the cores get bigger you see that core mass gets a bit more important; the SU90b yields more power than the SU90a proportional to core area.

However for the bigger cores the core area / power relationship stays within 2%; I call this very linear for practical purposes.

Apart from core area also core mass / magnetic path length have (minor) influence.

For the smaller SU48 core you see that the b version not quite manages the higher power relative to the a version; here core mass is more important.

As the cores get bigger you see that core mass gets a bit more important; the SU90b yields more power than the SU90a proportional to core area.

However for the bigger cores the core area / power relationship stays within 2%; I call this very linear for practical purposes.

P,

read your data again.

Plot it on a graph.

Plot W against various areas.

Plot W against (various areas)^2

Compare to your data.

Compare to the data I posted.

read your data again.

Plot it on a graph.

Plot W against various areas.

Plot W against (various areas)^2

Compare to your data.

Compare to the data I posted.

Andrew,

OK, let's try it another way:

SU48b should yield 3,47/2,19 x 26,5 = 42 W; P = 44,5 W, so 6% "more" than SU48a.

SU60b should yield 5,3/3,5 x 75,4 = 114 W; P = 116 W, so a bittle less than 2% "more"than SU60a.

SU75b should yield 9,01/5,63 x 188 = 301 W; P = 297 W, so a bit over 1% "less"than SU75a.

SU90b should yield 13,4/7,99 x 370 = 620 W; P = 610 W, so less than 2% "less"than SU90a.

Conclusion: the smaller cores benefit from the shorter magnetic path length, i.e. with the same path length doubling of core area yields a bit more than double the power. For the big cores (about 300W and bigger) the longer magnetic path length goes at the cost of power. A core of over 2000 W comes 4% "short" comparing different core areas.

Please note that these values are for this particular grade of silicon steel and core geometry (c-cores).

Don't you agree that for practical purposes the relationship can be regarded being linear??

OK, let's try it another way:

SU48b should yield 3,47/2,19 x 26,5 = 42 W; P = 44,5 W, so 6% "more" than SU48a.

SU60b should yield 5,3/3,5 x 75,4 = 114 W; P = 116 W, so a bittle less than 2% "more"than SU60a.

SU75b should yield 9,01/5,63 x 188 = 301 W; P = 297 W, so a bit over 1% "less"than SU75a.

SU90b should yield 13,4/7,99 x 370 = 620 W; P = 610 W, so less than 2% "less"than SU90a.

Conclusion: the smaller cores benefit from the shorter magnetic path length, i.e. with the same path length doubling of core area yields a bit more than double the power. For the big cores (about 300W and bigger) the longer magnetic path length goes at the cost of power. A core of over 2000 W comes 4% "short" comparing different core areas.

Please note that these values are for this particular grade of silicon steel and core geometry (c-cores).

Don't you agree that for practical purposes the relationship can be regarded being linear??

Andrew,

Not necessary; for me the relationship is linear enough regarding the material I work with.

My former posts are clear enough for all people except you it seems :-(

I give up; have some winding to do.

Cheers

Not necessary; for me the relationship is linear enough regarding the material I work with.

My former posts are clear enough for all people except you it seems :-(

I give up; have some winding to do.

Cheers

looking at the datasheets on toroid dot com, i make the following observations.

va/s per pound of transformer (includes copper, as they didn't specify core size)

increased from 50 to 60 va/lb, from 150 watts to 1000.

At the same time, full load temperature rise dropped from 70C to 50C.

the surface area of the transformers only increased from 47 square inches to 130 (surface area calculated as a cylinder, not as a toroid)

thus the watts per square inch of surface area increased from 3.5 w/in^2 to 7.5 w/in^2

rated Va's per watt of core loss didn't have a trend, but varied between 160 and 290.

had the smaller transformers been derated to keep the same temperature rise, watts per pound would have climbed much faster.

the actual core loss was insignificant, at about 1 watt per kilogram of iron.

the 1 kva transformer had 5.3 watts core loss, and weighs a total of 17 pounds.

va/s per pound of transformer (includes copper, as they didn't specify core size)

increased from 50 to 60 va/lb, from 150 watts to 1000.

At the same time, full load temperature rise dropped from 70C to 50C.

the surface area of the transformers only increased from 47 square inches to 130 (surface area calculated as a cylinder, not as a toroid)

thus the watts per square inch of surface area increased from 3.5 w/in^2 to 7.5 w/in^2

rated Va's per watt of core loss didn't have a trend, but varied between 160 and 290.

had the smaller transformers been derated to keep the same temperature rise, watts per pound would have climbed much faster.

the actual core loss was insignificant, at about 1 watt per kilogram of iron.

the 1 kva transformer had 5.3 watts core loss, and weighs a total of 17 pounds.

Jo,

could you refer me to the data.

I am trying to understand what you have observed and I can't reach any conclusions because too much is missing.

However I leave a couple of thoughts.

If you double the size of a transformer it's volume goes up by a factor of 8. By similarity the weight should also go up by a factor of 8.

The smallest transformer showing xVA @ yLBS

The largest transformer showing cVA @ dLBS.

Take the cube root of the weight. Square that root.

Now calculate VA/cuberoot(weight) and calculate VA/ [cuberoot(weight)] ^2

Do either of these show a linear relationship?

could you refer me to the data.

I am trying to understand what you have observed and I can't reach any conclusions because too much is missing.

However I leave a couple of thoughts.

If you double the size of a transformer it's volume goes up by a factor of 8. By similarity the weight should also go up by a factor of 8.

The smallest transformer showing xVA @ yLBS

The largest transformer showing cVA @ dLBS.

Take the cube root of the weight. Square that root.

Now calculate VA/cuberoot(weight) and calculate VA/ [cuberoot(weight)] ^2

Do either of these show a linear relationship?

Pietr,

I take the time to read your posts. I spend time thinking about what the message is. I reach a considered conclusion.

Would you please plot a graph of the 8 datapoints.

I take the time to read your posts. I spend time thinking about what the message is. I reach a considered conclusion.

Would you please plot a graph of the 8 datapoints.

AndrewT, I have not been following closely, just wanted to interject, double the core material, double the power, ignoring wire, surface area, blah blah. You got that far by now right?

You may find through a lot of research that there is Tons of fudge in the world of transformer design unless you want to go all the way back to Maxwell's equations and spend all day calculating a transformer that doesn't actually do what was calculated because a bunch of factors' tolerance stacks up to be well over 10% off.

You may find through a lot of research that there is Tons of fudge in the world of transformer design unless you want to go all the way back to Maxwell's equations and spend all day calculating a transformer that doesn't actually do what was calculated because a bunch of factors' tolerance stacks up to be well over 10% off.

Last edited:

Tony,

These RDH formulas apply for prehistoric quality cores; you cannot use them for nowadays quality grain oriented cores.

I use grain oriented silicon steel c-cores, strip thickness 0.3 mm, for power supply transformers.

SU48b, SU60b, SU75b and SU90b are c-cores I use, single or stacked (the stacked core is still a "single" core with two coils, one on each leg of the c-core).

These b versions are higher than the a versions, which have the same core profile (magnetic path length).

See here the secondary power rating for these cores, and you will see that the difference in core area for the a and b versions is almost 100% proportional to the difference in power:

so what has changed to irons since then? any links/documentation i can look at?

here is a program that will assist you in finding out primary turns of power transformers:

Silvio Klaic's electronic section

i have used it with much success, it gives you a good idea how to make your own traffos..

Silvio Klaic's electronic section

i have used it with much success, it gives you a good idea how to make your own traffos..

so what has changed to irons since then? any links/documentation i can look at?

The J & P transformer book: a ... - Google Books

there's a short history in there, about 15 pages long.

pete millete's on-line books: they are free to download,

Technical books online

another very helpful site:

http://www.turneraudio.com.au/powertranschokes.htm

my work:

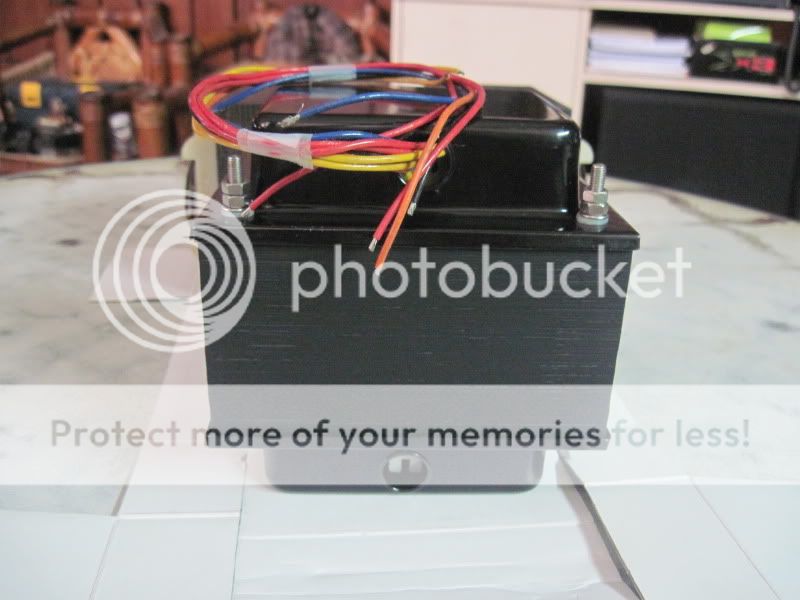

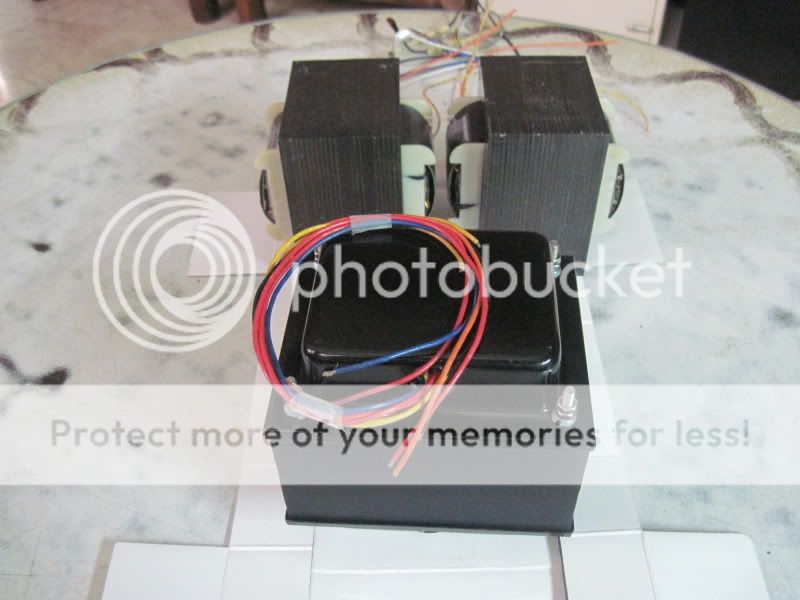

this is a plate traffo for my upcoming tube amp, it has 1 3/4 in x 3 inch core on a DEECO bobbin, endbells from FETRONICS:

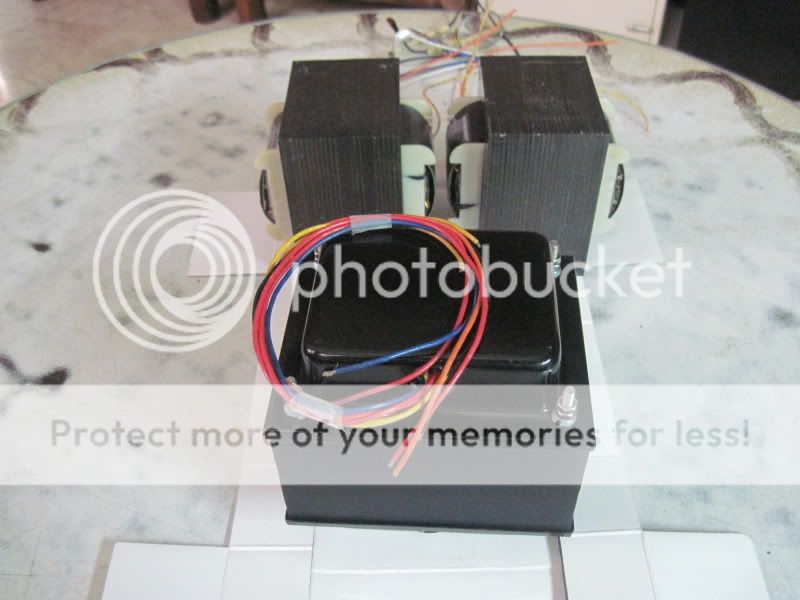

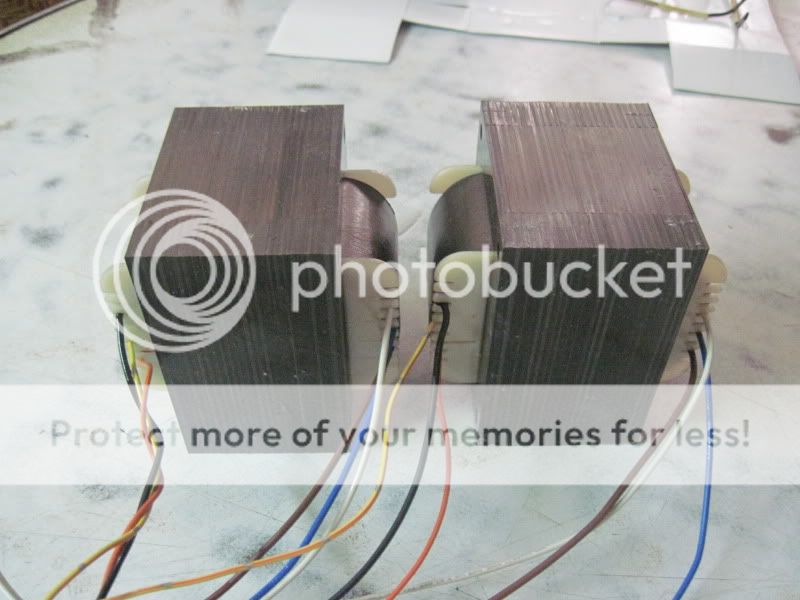

the 2 smaller traffos are OPT's , 3k plate to plate to 4/8 ohm secondaries:

Technical books online

another very helpful site:

http://www.turneraudio.com.au/powertranschokes.htm

my work:

this is a plate traffo for my upcoming tube amp, it has 1 3/4 in x 3 inch core on a DEECO bobbin, endbells from FETRONICS:

the 2 smaller traffos are OPT's , 3k plate to plate to 4/8 ohm secondaries:

Last edited:

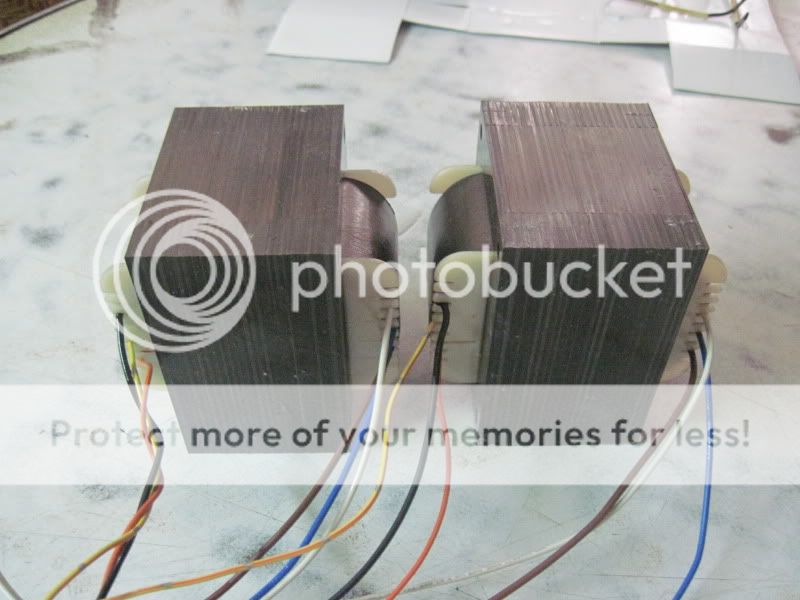

POWER TRANSFORMER VA and core size/area

Tony,

it took me a while to track down a virtual copy of the Radiotron handbook.

Chapter5 on transformers, section5 Power Transformers states.

rearranging the formula gives

VA = 31 A^2 where A is the core area in square inches.

Tony,

it took me a while to track down a virtual copy of the Radiotron handbook.

Chapter5 on transformers, section5 Power Transformers states.

rearranging the formula gives

VA = 31 A^2 where A is the core area in square inches.

Attachments

AndrewT,

Your reference is wrong. Don't believe everything you read. Searching for something that is wrong is a waste of time. Look up some of the core vendor applications literature. You will find the power handling capability of a core is directly proportional to Ac, not Ac^2.

Rick

Your reference is wrong. Don't believe everything you read. Searching for something that is wrong is a waste of time. Look up some of the core vendor applications literature. You will find the power handling capability of a core is directly proportional to Ac, not Ac^2.

Rick

i'd rather believe in the Radiotron Designer's Handbooks than take your words....🙂

anyways, that formula is a guide so that you have more or less a clear idea of what the power handling capability of a given core could be....

real world designs will vary all over the place.....

anyways, that formula is a guide so that you have more or less a clear idea of what the power handling capability of a given core could be....

real world designs will vary all over the place.....

- Status

- Not open for further replies.

- Home

- Amplifiers

- Power Supplies

- Stacking Cores