In this series of posts I will give an introduction to SpeakerBench. The presentation is based on a 2-part article Claus Futtrup and I wrote this year for audioXpress magazine. Rather than a general discussion, we focus on a specific application: leakage loss as identified with our proposed advanced transducer model. The advanced model is compared to classical Thiele/Small modeling, with reference to detailed in-box measurements.

Last edited by a moderator:

Speakerbench -- part 2

History of the Thiele/Small Approach

When Neville Thiele and Richard Small presented their work on loudspeaker modeling in the 1960s and 1970s, it was a revolution in the industry. Instead of guessing a suitable box volume and iterating towards a particular target, simulations could predict the behavior (within reasonable bounds) provided that one knew the Thiele/Small (T/S) parameters beforehand. Although this work is still considered foundational, loudspeaker technology and development has progressed significantly since then.

Early 90s design software included LinearX with their LMS measurement system, and LEAP box and crossover simulations. Today, advanced measurement equipment from Klippel GmbH is standard in laboratories around the world. The older LEAP system is Windows-XP-era software and is fading away with no replacement in sight. Interestingly, as transducer manufacturers have become better at measuring their products, and the quality of datasheets have improved, system designers are increasingly relying on this data and not measuring the drivers prior to designing a system. The usual manufacturer dataset includes simplified T/S parameters, a simplified measure of the inductance, and a few other key parameters like Xmax.

In spite of decades of progress, the fundamental approach to loudspeaker parameter estimation and box simulation hasn't changed. It remains based on 1970s T/S parameters and simple mechanical parameters. In reality, however, the driver exhibits viscoelastic effects in the suspension, and non-inductive elements in the motor, that are beyond the physical scope of the T/S model. The difference between the latter model and a more comprehensive model of the driver can potentially be a few dB when designing a vented system. Because loudspeakers are now developed with computer modeling, rather than hand calculations, more comprehensive new models of the transducer can be practically considered. Specifically, we can include viscoelastic damping in the suspension, as well as a voice coil model including semi-inductive effects. Speakerbench is based on a new advanced model for transducer behavior that we believe is robust enough to serve as a new standard going forward.

History of the Thiele/Small Approach

When Neville Thiele and Richard Small presented their work on loudspeaker modeling in the 1960s and 1970s, it was a revolution in the industry. Instead of guessing a suitable box volume and iterating towards a particular target, simulations could predict the behavior (within reasonable bounds) provided that one knew the Thiele/Small (T/S) parameters beforehand. Although this work is still considered foundational, loudspeaker technology and development has progressed significantly since then.

Early 90s design software included LinearX with their LMS measurement system, and LEAP box and crossover simulations. Today, advanced measurement equipment from Klippel GmbH is standard in laboratories around the world. The older LEAP system is Windows-XP-era software and is fading away with no replacement in sight. Interestingly, as transducer manufacturers have become better at measuring their products, and the quality of datasheets have improved, system designers are increasingly relying on this data and not measuring the drivers prior to designing a system. The usual manufacturer dataset includes simplified T/S parameters, a simplified measure of the inductance, and a few other key parameters like Xmax.

In spite of decades of progress, the fundamental approach to loudspeaker parameter estimation and box simulation hasn't changed. It remains based on 1970s T/S parameters and simple mechanical parameters. In reality, however, the driver exhibits viscoelastic effects in the suspension, and non-inductive elements in the motor, that are beyond the physical scope of the T/S model. The difference between the latter model and a more comprehensive model of the driver can potentially be a few dB when designing a vented system. Because loudspeakers are now developed with computer modeling, rather than hand calculations, more comprehensive new models of the transducer can be practically considered. Specifically, we can include viscoelastic damping in the suspension, as well as a voice coil model including semi-inductive effects. Speakerbench is based on a new advanced model for transducer behavior that we believe is robust enough to serve as a new standard going forward.

Last edited by a moderator:

Speakerbench -- part 3

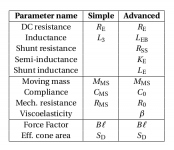

Simple versus Advanced Model Parameters

In the attached table, we compare the simple parameters (from which the T/S parameters were derived) with the advanced parameter set. The effective cone area, SD, and force factor, Bl, are common to both models. Whereas the simple model describes the electrical impedance with 2 parameters, the advanced model uses 5. And whereas the simple model describes the motional impedance with 3 parameters, the advanced model uses 4. In the simple model one assumes a pure inductance as L3 indicating that the value corresponds to the +3 dB point of the impedance magnitude (this choice represents a sort of industry consensus). Note that L3 is sometimes named LE, but it is important to keep in mind that typically this is only a crude approximation for the true motor impedance. On the mechanical side, a viscoelastic parameter, β, is included in the advanced model. The viscoelasticity implies that the compliance and mechanical resistance are fundamentally changed and must be recomputed; these are C0, R0. The moving mass MMS retains its usual physical definition.

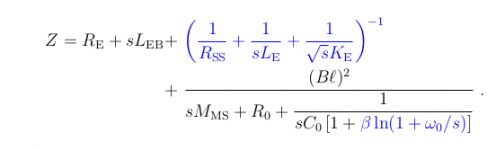

In the attached equation, we show in black print the simple parameters (to recover the simple model, replace LEB with L3 and R0, C0 with the legacy RMS, CMS) and in blue print the additional advanced parameters. We set ω0 to 1.5 times the resonance frequency of the driver. This term provides a cutoff for the viscoelasticity.

Simple versus Advanced Model Parameters

In the attached table, we compare the simple parameters (from which the T/S parameters were derived) with the advanced parameter set. The effective cone area, SD, and force factor, Bl, are common to both models. Whereas the simple model describes the electrical impedance with 2 parameters, the advanced model uses 5. And whereas the simple model describes the motional impedance with 3 parameters, the advanced model uses 4. In the simple model one assumes a pure inductance as L3 indicating that the value corresponds to the +3 dB point of the impedance magnitude (this choice represents a sort of industry consensus). Note that L3 is sometimes named LE, but it is important to keep in mind that typically this is only a crude approximation for the true motor impedance. On the mechanical side, a viscoelastic parameter, β, is included in the advanced model. The viscoelasticity implies that the compliance and mechanical resistance are fundamentally changed and must be recomputed; these are C0, R0. The moving mass MMS retains its usual physical definition.

In the attached equation, we show in black print the simple parameters (to recover the simple model, replace LEB with L3 and R0, C0 with the legacy RMS, CMS) and in blue print the additional advanced parameters. We set ω0 to 1.5 times the resonance frequency of the driver. This term provides a cutoff for the viscoelasticity.

Attachments

Last edited by a moderator:

Speakerbench -- part 4

Simple vs Advanced Model for Lossless Enclosures

In order to illustrate the magnitude of the correction to be expected when using the advanced model, we present a box simulation example using the SEAS H1488-08 (L16RNX) midwoofer. Using Speakerbench, we model the SEAS driver in a vented box with volume Vb=26l and port tuning Fp=39.5Hz. All box losses (leakage, port, absorption) are taken to be negligible. Note that the 26l box (shown in part 1) was constructed for testing purposes only, with a removable baffle that accepts numerous drivers. As such it should not be considered to be an optimal box for the L16RNX.

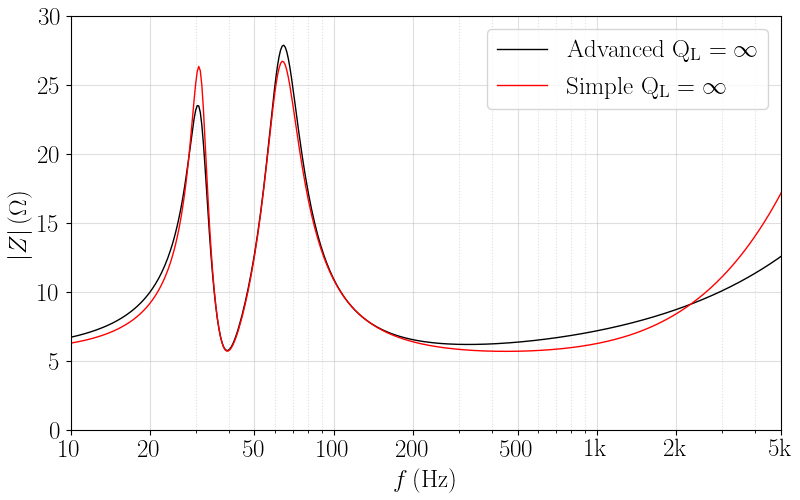

In the attached figure we plot the total modeled system impedance in a lossless enclosure for the simple (red curve) and advanced (black curve) transducer models. The simple model exhibits the familiar result that both impedance peaks are nearly the same height. In contrast, the advanced model exhibits offset peaks, with the high-frequency (HF) peak increased in amplitude, and the low-frequency (LF) peak reduced in amplitude. This important asymmetry is a manifestation of the frequency-dependent viscoelastic damping.

Simple vs Advanced Model for Lossless Enclosures

In order to illustrate the magnitude of the correction to be expected when using the advanced model, we present a box simulation example using the SEAS H1488-08 (L16RNX) midwoofer. Using Speakerbench, we model the SEAS driver in a vented box with volume Vb=26l and port tuning Fp=39.5Hz. All box losses (leakage, port, absorption) are taken to be negligible. Note that the 26l box (shown in part 1) was constructed for testing purposes only, with a removable baffle that accepts numerous drivers. As such it should not be considered to be an optimal box for the L16RNX.

In the attached figure we plot the total modeled system impedance in a lossless enclosure for the simple (red curve) and advanced (black curve) transducer models. The simple model exhibits the familiar result that both impedance peaks are nearly the same height. In contrast, the advanced model exhibits offset peaks, with the high-frequency (HF) peak increased in amplitude, and the low-frequency (LF) peak reduced in amplitude. This important asymmetry is a manifestation of the frequency-dependent viscoelastic damping.

Last edited by a moderator:

Speakerbench -- part 5

Models vs Reality for Lossless Enclosures

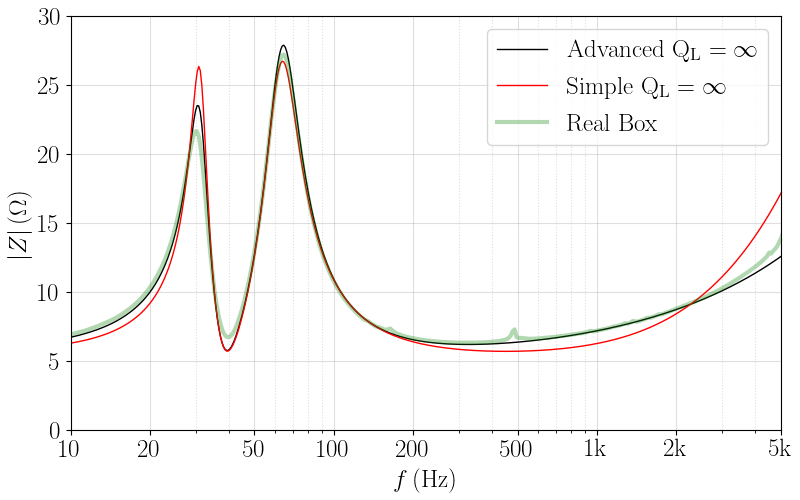

Without measuring the driver in a real enclosure, it is difficult to gauge the absolute accuracy of the simulations. In the attached figure, we measured the impedance of a midwoofer mounted in a real 26l enclosure, tuned to Fp=39.5Hz. The measured impedance is shown as the thick green curve. Of course the real enclosure is not perfectly lossless so we expect the impedance maxima to be reduced in height somewhat in comparison to the lossless simulations.

Note the measured HF peak (green) is above the simple model peak (red). We emphasize that there is no way to correct this result by adding losses to the simple model, as doing so will only reduce the peak height. On the other hand, the advanced model LF and HF peaks (black) are above the measured peaks (green), suggesting that better agreement may be achieved by adding box losses to the simulation.

Models vs Reality for Lossless Enclosures

Without measuring the driver in a real enclosure, it is difficult to gauge the absolute accuracy of the simulations. In the attached figure, we measured the impedance of a midwoofer mounted in a real 26l enclosure, tuned to Fp=39.5Hz. The measured impedance is shown as the thick green curve. Of course the real enclosure is not perfectly lossless so we expect the impedance maxima to be reduced in height somewhat in comparison to the lossless simulations.

Note the measured HF peak (green) is above the simple model peak (red). We emphasize that there is no way to correct this result by adding losses to the simple model, as doing so will only reduce the peak height. On the other hand, the advanced model LF and HF peaks (black) are above the measured peaks (green), suggesting that better agreement may be achieved by adding box losses to the simulation.

Last edited by a moderator:

Speakerbench -- part 6

Influence of Leakage Loss

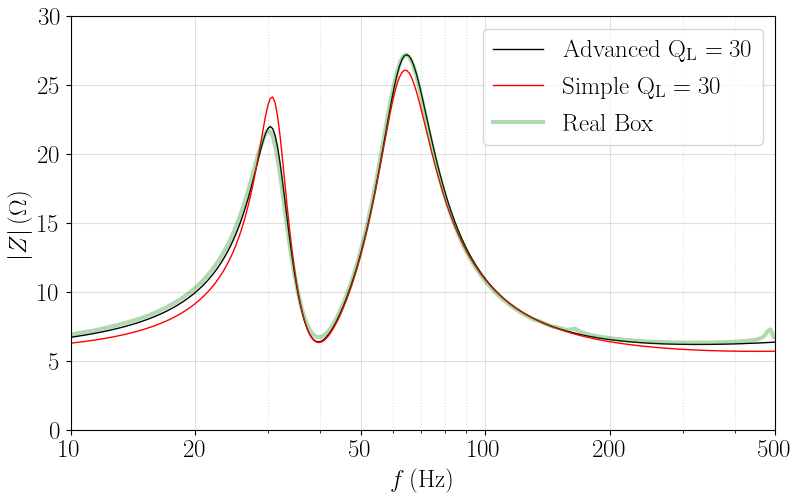

Although there are numerous potential loss channels (leakage, port, absorption), for simplicity we consider simulations with leakage loss only. This is the approach typically used by Small since it simplifies the analytic analysis. Setting QL = 30 in the simulations give the excellent advanced model result shown in the attached figure. This suggests a total enclosure loss no greater than QB ~ 30.

The critical observation is that, with QL = 30, the simple model still exhibits the LF/HF overshoot/undershoot of the lossless case. For this reason, it is difficult to estimate the true magnitude of the enclosure losses with the simple T/S model.

Influence of Leakage Loss

Although there are numerous potential loss channels (leakage, port, absorption), for simplicity we consider simulations with leakage loss only. This is the approach typically used by Small since it simplifies the analytic analysis. Setting QL = 30 in the simulations give the excellent advanced model result shown in the attached figure. This suggests a total enclosure loss no greater than QB ~ 30.

The critical observation is that, with QL = 30, the simple model still exhibits the LF/HF overshoot/undershoot of the lossless case. For this reason, it is difficult to estimate the true magnitude of the enclosure losses with the simple T/S model.

Last edited by a moderator:

Speakerbench -- part 7

Connection to Small's Rule

In assessing losses in practical enclosures, Richard Small (and previous authors) noticed that measured losses appeared to exceed theoretical expectations. Small inferred that even though the true leakage loss is insignificant, system losses somehow manifest as QL ~ 5-10 (Ref 1; references are given in Part 15). For this reason, an engineering rule of thumb emerged such that designers set QL = 7 for modeling purposes. This value was intended to broadly cover several types of losses (not only leakage but also absorption in the box). The analysis presented in the previous parts, however, leads us to suggest that the anomalous loss (correctly) observed by Small is a result not of the enclosure but of the driver -- specifically, driver viscoelasticity that is not included in the simple model. We further claim that corrections like Small's rule are not necessary (and not recommended) when using the advanced model.

Regarding accurate estimate of true losses, the simple model does not capture the asymmetry in the impedance peaks (as shown in Part 6). For this reason there is no obvious methodology to arrive at an accurate estimate of true enclosure losses using the simple model. With the advanced model, however, an accurate estimate of the true losses can be made.

Finally, it is well-known that measuring free-field frequency response at low frequencies is practically impossible (requiring a very large anechoic chamber). Conversely, measuring the impedance of a loudspeaker to very high precision is possible with low-cost equipment. By matching the measured to simulated impedance (as in Part 6), one can have confidence that the modeled low-frequency SPL is accurate and correctly includes all losses. Further, potential errors (for example, a real enclosure leak) are not easily identified in a frequency response measurement but will be readily apparent in an impedance measurement.

Connection to Small's Rule

In assessing losses in practical enclosures, Richard Small (and previous authors) noticed that measured losses appeared to exceed theoretical expectations. Small inferred that even though the true leakage loss is insignificant, system losses somehow manifest as QL ~ 5-10 (Ref 1; references are given in Part 15). For this reason, an engineering rule of thumb emerged such that designers set QL = 7 for modeling purposes. This value was intended to broadly cover several types of losses (not only leakage but also absorption in the box). The analysis presented in the previous parts, however, leads us to suggest that the anomalous loss (correctly) observed by Small is a result not of the enclosure but of the driver -- specifically, driver viscoelasticity that is not included in the simple model. We further claim that corrections like Small's rule are not necessary (and not recommended) when using the advanced model.

Regarding accurate estimate of true losses, the simple model does not capture the asymmetry in the impedance peaks (as shown in Part 6). For this reason there is no obvious methodology to arrive at an accurate estimate of true enclosure losses using the simple model. With the advanced model, however, an accurate estimate of the true losses can be made.

Finally, it is well-known that measuring free-field frequency response at low frequencies is practically impossible (requiring a very large anechoic chamber). Conversely, measuring the impedance of a loudspeaker to very high precision is possible with low-cost equipment. By matching the measured to simulated impedance (as in Part 6), one can have confidence that the modeled low-frequency SPL is accurate and correctly includes all losses. Further, potential errors (for example, a real enclosure leak) are not easily identified in a frequency response measurement but will be readily apparent in an impedance measurement.

Last edited by a moderator:

Speakerbench -- part 8

Community/Industry Acceptance of Advanced Parameters

Although transducer manufacturers are likely to have a Klippel analyzer in their laboratory, they rarely publish viscoelastic data. Measurement files from the Klippel analyzer are not readily available for download, and moreover, we do not know of any available software which can process this data and use it for box simulation. Claus initially thought that it would take a few years for some in the industry to adopt advanced parameters once the advantages were understood. Alas, 10 years after his presentation at a 2011 AES Convention in London (Ref 2), and although the work has caught the attention of both industry professionals and DIYers, few people do box simulation using the advanced model. Indeed, significant reformulations and software changes are required to move away from the simple T/S parameters.

Claus and I have advocated for some years for the acceptance of the advanced parameter description. To this end, we have published the relevant theoretical details, and have overcome certain obstacles; most notably, how to measure the viscoelasticity without expensive equipment (Ref 3), how to work with the advanced model in the time domain (Ref 5), and how to derive equivalent simple model parameters from the advanced parameters.

Community/Industry Acceptance of Advanced Parameters

Although transducer manufacturers are likely to have a Klippel analyzer in their laboratory, they rarely publish viscoelastic data. Measurement files from the Klippel analyzer are not readily available for download, and moreover, we do not know of any available software which can process this data and use it for box simulation. Claus initially thought that it would take a few years for some in the industry to adopt advanced parameters once the advantages were understood. Alas, 10 years after his presentation at a 2011 AES Convention in London (Ref 2), and although the work has caught the attention of both industry professionals and DIYers, few people do box simulation using the advanced model. Indeed, significant reformulations and software changes are required to move away from the simple T/S parameters.

Claus and I have advocated for some years for the acceptance of the advanced parameter description. To this end, we have published the relevant theoretical details, and have overcome certain obstacles; most notably, how to measure the viscoelasticity without expensive equipment (Ref 3), how to work with the advanced model in the time domain (Ref 5), and how to derive equivalent simple model parameters from the advanced parameters.

Last edited by a moderator:

Speakerbench -- part 9

Speakerbench: A Free Community Web-App

The first step in the proposed modeling workflow is to compute the advanced model parameter set, and for this purpose we created the Dual-Added-Mass method. The details of this method are described in a recent AES article (Ref 3). The approach is verified to be capable of determining Bl within 1.0% and MMS within 2%. In particular, the viscoelastic parameter, β, as well as the advanced electrical parameters, are extracted from the measured data. The procedure offers a formal sanity-check for the measurement quality, unlike the classical added-mass method for which seasoned engineers would normally rely on experience and intuition to assess the quality of the extracted model parameters. Although the dual-added-mass procedure has been well-documented, it is non-trivial to design an algorithm to robustly carry out the parameter fitting and make an objective error estimate. Thus, to facilitate use and adoption of the advanced model, we have created a web-application named Speakerbench, available online at speakerbench.com. The user must only perform three impedance measurements with suitable equipment, and Speakerbench does the rest. The transducer data from the app is provided in JSON format (equivalent to a python dictionary) and can be downloaded and shared across the globe.

Unlike DLC Dumax, LinearX and Klippel data, the results from Speakerbench are valid only in the small-signal domain, but the data is of high quality and suitable for box design. After the advanced parameters are computed, the user can further carry out box simulations within Speakerbench, or export to dedicated design software, such as VituixCAD.

Speakerbench: A Free Community Web-App

The first step in the proposed modeling workflow is to compute the advanced model parameter set, and for this purpose we created the Dual-Added-Mass method. The details of this method are described in a recent AES article (Ref 3). The approach is verified to be capable of determining Bl within 1.0% and MMS within 2%. In particular, the viscoelastic parameter, β, as well as the advanced electrical parameters, are extracted from the measured data. The procedure offers a formal sanity-check for the measurement quality, unlike the classical added-mass method for which seasoned engineers would normally rely on experience and intuition to assess the quality of the extracted model parameters. Although the dual-added-mass procedure has been well-documented, it is non-trivial to design an algorithm to robustly carry out the parameter fitting and make an objective error estimate. Thus, to facilitate use and adoption of the advanced model, we have created a web-application named Speakerbench, available online at speakerbench.com. The user must only perform three impedance measurements with suitable equipment, and Speakerbench does the rest. The transducer data from the app is provided in JSON format (equivalent to a python dictionary) and can be downloaded and shared across the globe.

Unlike DLC Dumax, LinearX and Klippel data, the results from Speakerbench are valid only in the small-signal domain, but the data is of high quality and suitable for box design. After the advanced parameters are computed, the user can further carry out box simulations within Speakerbench, or export to dedicated design software, such as VituixCAD.

Last edited by a moderator:

Speakerbench -- part 10

Steps In Creating An Advanced Transducer Model and Datasheet

The two requirements for good results with Speakerbench are (1) a sufficiently accurate setup for impedance measurements, and (2) a quality scale for measuring the added masses. Measuring impedance should either be executed with a stepped-sine where each measurement is allowed to stabilize, or alternatively in a slow sweep (say minimum 10 seconds and preferably with a sweep profile that gives you more time at the lower frequencies). Measuring with 0.1 gram precision is mandatory for normal transducers with MMS in the 10g-25g range.

Let's walk through the process.

Collect 4 masses (using, for instance, a combination of Blu Tack and nuts) to be added to the diaphragm of the transducer. We recommend that total mass, which we denote by m2, be close to the moving mass of the driver. This is just a guideline and not essential. The progression of the driver measurements is shown in the image below:

STEPS

Steps In Creating An Advanced Transducer Model and Datasheet

The two requirements for good results with Speakerbench are (1) a sufficiently accurate setup for impedance measurements, and (2) a quality scale for measuring the added masses. Measuring impedance should either be executed with a stepped-sine where each measurement is allowed to stabilize, or alternatively in a slow sweep (say minimum 10 seconds and preferably with a sweep profile that gives you more time at the lower frequencies). Measuring with 0.1 gram precision is mandatory for normal transducers with MMS in the 10g-25g range.

Let's walk through the process.

Collect 4 masses (using, for instance, a combination of Blu Tack and nuts) to be added to the diaphragm of the transducer. We recommend that total mass, which we denote by m2, be close to the moving mass of the driver. This is just a guideline and not essential. The progression of the driver measurements is shown in the image below:

STEPS

- Attach the 4 masses, distributing them evenly near the voice coil (or just outside the area where the dust cap is attached) to ensure the load is balanced evenly to avoid rocking modes. This mass distribution is shown in the left panel in the image above.

- Measure the impedance of the transducer in free air, with all 4 pieces attached to the cone (left panel). This is the m2 impedance measurement.

- Gently remove two diagonal pieces such that about half the added mass remains on the cone (center panel). Remeasure the impedance with the remaining mass (m1) on the cone. For reference, weigh the removed mass (m2-m1) on a precision scale. When you remove the masses, avoid moving the cone (it should remain in its rest position).

- Gently remove the remaining two masses (right panel) and remeasure impedance. This is the unweighted measurement. Weigh the removed mass (m1) on a precision scale. Sum the two weights to calculate the total mass, m2.

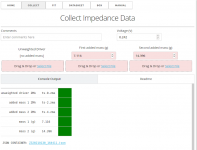

- Upload the three impedance measurements and the associated masses (m2 and m1) into the COLLECT app (see collect.png), then download the resulting JSON Z-file.

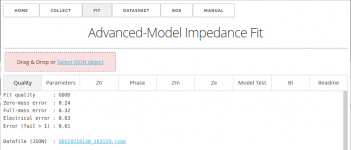

- Upload the Z-file from Step 5 into the FIT app (see fit.png). Speakerbench will then compute the advanced model parameters, as well as a quality of the fit metric that can be assessed in the resulting plot windows. The advanced parameters are provided in a downloadable JSON ADV-file.

- Upload the ADV-file into the DATASHEET app (see creator.png). Here you simply add a description of the driver you've measured and a few important parameters, like SD and maybe XMAX, and the datasheet is then complete, provided in a downloadable JSON SBD-file.

Attachments

Last edited by a moderator:

Speakerbench -- part 11

Fit Quality Assessment

By performing three impedance measurements instead of two (as in the classic added-mass method), the pure motional impedance can be extracted with a minimum of model assumptions. From this pure motional impedance, the viscoelastic parameter, β, is then determined. The remaining blocked-electrical impedance can be derived by a relatively simple set of algebraic operations. As part of the analysis, the algorithm attempts to extract a stable value of Bl over a region of about one octave around the resonant frequency. This approach gives a useful indication of the robustness of the overall fit.

After the fitting procedure is complete (step 6) the fit quality is automatically assessed. In the Quality tab of the FIT app, a fit rating is provided (see fit.png in part 10). This means you don't have to be an expert in analyzing the output from the fitter. Possible ratings are

Beyond these simple ratings, the user can also study the graphs in the succeeding tabs, where the app provides plots of the motional impedance (ZM), the blocked-electrical impedance (ZE), a model test which essentially compares your three measurements with the simulations based on the established model parameters, and Bl over the fit range. To get an excellent rating probably requires some practice and experimentation with the added mass approach. The good rating is nevertheless sufficient for reasonably accurate box simulations. The Speakerbench article in the Loudspeaker Industry Sourcebook 2020 explains more about this (Ref 4).

Fit Quality Assessment

By performing three impedance measurements instead of two (as in the classic added-mass method), the pure motional impedance can be extracted with a minimum of model assumptions. From this pure motional impedance, the viscoelastic parameter, β, is then determined. The remaining blocked-electrical impedance can be derived by a relatively simple set of algebraic operations. As part of the analysis, the algorithm attempts to extract a stable value of Bl over a region of about one octave around the resonant frequency. This approach gives a useful indication of the robustness of the overall fit.

After the fitting procedure is complete (step 6) the fit quality is automatically assessed. In the Quality tab of the FIT app, a fit rating is provided (see fit.png in part 10). This means you don't have to be an expert in analyzing the output from the fitter. Possible ratings are

(1) EXCELLENT, (2) GOOD, (3) FAIR, and (4) FAIL.

Beyond these simple ratings, the user can also study the graphs in the succeeding tabs, where the app provides plots of the motional impedance (ZM), the blocked-electrical impedance (ZE), a model test which essentially compares your three measurements with the simulations based on the established model parameters, and Bl over the fit range. To get an excellent rating probably requires some practice and experimentation with the added mass approach. The good rating is nevertheless sufficient for reasonably accurate box simulations. The Speakerbench article in the Loudspeaker Industry Sourcebook 2020 explains more about this (Ref 4).

Last edited by a moderator:

Speakerbench -- part 12

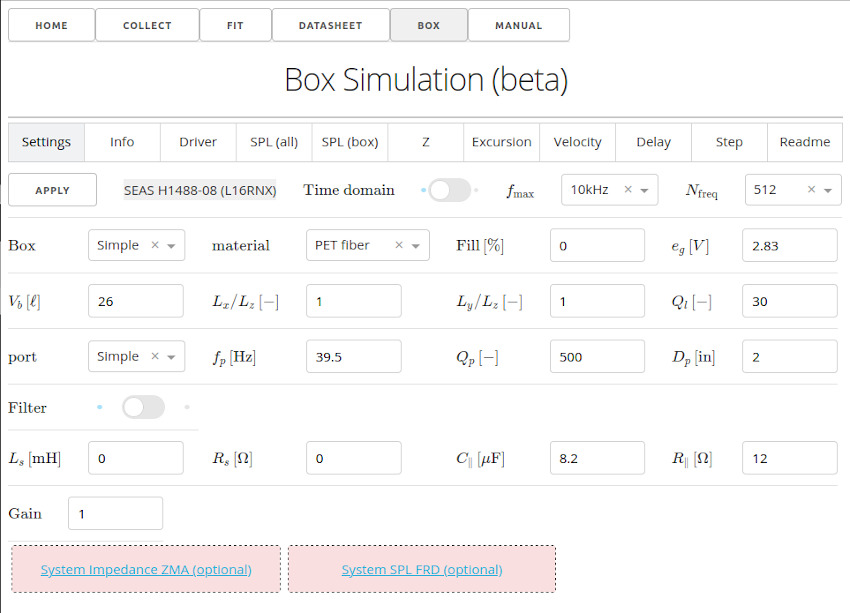

Box simulations with Speakerbench

Speakerbench wasn't initially intended to do box simulations, but there were numerous motivations to offer this functionality. Once an SBD file is created or uploaded, the transducer parameters are automatically forwarded into the BOX app (see box.png), and an initial proposal for a box is provided. Just push the BOX button at the top. You can then explore the Settings to find an optimal configuration. In the box simulator you may specify the usual box parameters, including damping material, input voltage, box volume, port model, tuning frequency and even a simple passive filter. The usual array of plots are produced, including the step response which is calculated with a special-purpose algorithm that is compatible with the non-polynomial form of the advanced response function. At the bottom of the GUI you can upload SPL or impedance measurements and compare with the simulation.

Some aspects of the box model -- particularly enclosure geometry and fill effects -- will be improved over time.

Box simulations with Speakerbench

Speakerbench wasn't initially intended to do box simulations, but there were numerous motivations to offer this functionality. Once an SBD file is created or uploaded, the transducer parameters are automatically forwarded into the BOX app (see box.png), and an initial proposal for a box is provided. Just push the BOX button at the top. You can then explore the Settings to find an optimal configuration. In the box simulator you may specify the usual box parameters, including damping material, input voltage, box volume, port model, tuning frequency and even a simple passive filter. The usual array of plots are produced, including the step response which is calculated with a special-purpose algorithm that is compatible with the non-polynomial form of the advanced response function. At the bottom of the GUI you can upload SPL or impedance measurements and compare with the simulation.

Some aspects of the box model -- particularly enclosure geometry and fill effects -- will be improved over time.

Last edited by a moderator:

Speakerbench -- part 13

JSON Format and Portability

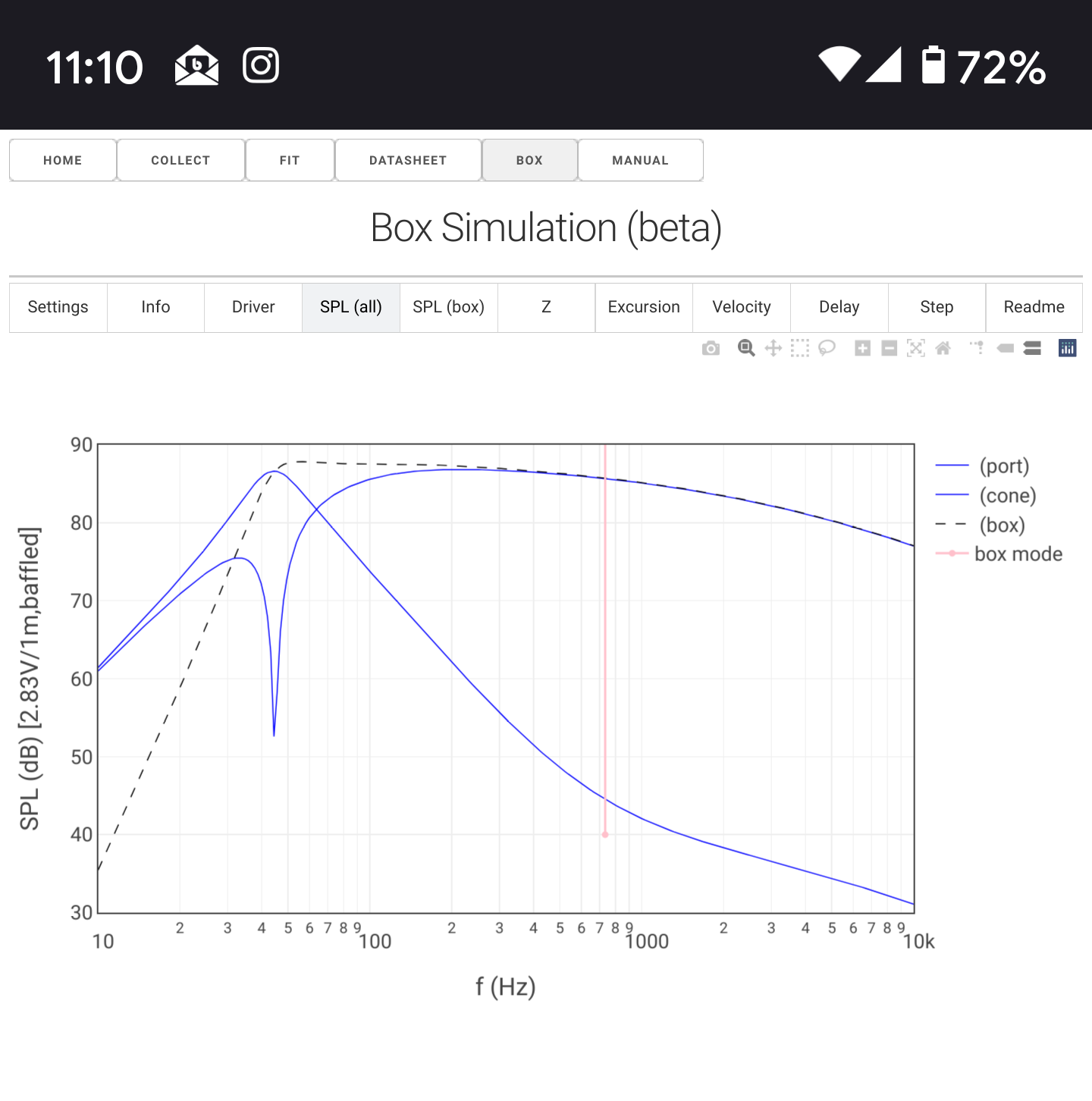

Speakerbench makes use of JSON as a standard container for calculation and datasheet output. This way you can share datasheets and simulations easily with fellow speaker designers. An online database of datasheets (SBD files) could easily be deployed, if desired. If someone sends you a Z-file or ADV-file or SBD-file, you can download it to your smartphone and then drop it into Speakerbench running on a browser. Or you can run it directly on your smartphone or tablet (see attached image).

JSON Format and Portability

Speakerbench makes use of JSON as a standard container for calculation and datasheet output. This way you can share datasheets and simulations easily with fellow speaker designers. An online database of datasheets (SBD files) could easily be deployed, if desired. If someone sends you a Z-file or ADV-file or SBD-file, you can download it to your smartphone and then drop it into Speakerbench running on a browser. Or you can run it directly on your smartphone or tablet (see attached image).

Last edited by a moderator:

Speakerbench -- part 14

Why Speakerbench?

What makes Speakerbench unique is that high-quality transducer data can ensured even for the do-it-yourself speaker builder. The improvement in accuracy with the advanced model can be readily achieved, and should prove useful particularly when quantifying the various box losses. The user should be able to easily and accurately determine a suitable box volume. Speaker designers (DIYers or professionals) rarely build more than one box to determine the optimal volume for a loudspeaker system. With that one prototype box, you just have to make things work. This explains why it is so important to determine the best box volume and port tuning from the very beginning.

Moreover, Speakerbench is a web-app and works on any computer, tablet or smartphone with a browser without any software installation required. The online version will always be up-to-date with the latest that we have made available. Speakerbench collects the research and the proposed methods into an easily accessible software suite. We do the software development, as well as the underlying research and modeling, to help the industry move forward and improve their methods. It is our hope that Speakerbench will facilitate the jump from legacy Thiele/Small parameters to more advanced modeling, and that people will feel like giving it a chance. A manual is available on the website, and in addition we have created a series of short tutorial videos available on YouTube.

Why Speakerbench?

What makes Speakerbench unique is that high-quality transducer data can ensured even for the do-it-yourself speaker builder. The improvement in accuracy with the advanced model can be readily achieved, and should prove useful particularly when quantifying the various box losses. The user should be able to easily and accurately determine a suitable box volume. Speaker designers (DIYers or professionals) rarely build more than one box to determine the optimal volume for a loudspeaker system. With that one prototype box, you just have to make things work. This explains why it is so important to determine the best box volume and port tuning from the very beginning.

Moreover, Speakerbench is a web-app and works on any computer, tablet or smartphone with a browser without any software installation required. The online version will always be up-to-date with the latest that we have made available. Speakerbench collects the research and the proposed methods into an easily accessible software suite. We do the software development, as well as the underlying research and modeling, to help the industry move forward and improve their methods. It is our hope that Speakerbench will facilitate the jump from legacy Thiele/Small parameters to more advanced modeling, and that people will feel like giving it a chance. A manual is available on the website, and in addition we have created a series of short tutorial videos available on YouTube.

Last edited by a moderator:

Speakerbench -- part 15

References

(1) R. Small, Vented-Box Loudspeaker Systems -- Part 1: Small-Signal Analysis, J. Audio Eng. Soc. 21 (1973) 363

(2) C. Futtrup, Losses in Loudspeaker Enclosures, AES Convention Paper 8324, London, UK (2011)

(3) J. Candy and C. Futtrup, An Added-Mass Measurement Technique for Transducer Parameter Estimation, J. Audio Eng. Soc. 65 (2017) 1005

(4) C. Futtrup and J. Candy, Speakerbench, Loudspeaker Industry Sourcebook, Feature Article (2020) 124-131.

(5) J. Candy and C. Futtrup, A Contour Integral Method for Time-Domain Response Calculations, J. Audio Eng. Soc. 66 (2018) 360

References

(1) R. Small, Vented-Box Loudspeaker Systems -- Part 1: Small-Signal Analysis, J. Audio Eng. Soc. 21 (1973) 363

(2) C. Futtrup, Losses in Loudspeaker Enclosures, AES Convention Paper 8324, London, UK (2011)

(3) J. Candy and C. Futtrup, An Added-Mass Measurement Technique for Transducer Parameter Estimation, J. Audio Eng. Soc. 65 (2017) 1005

(4) C. Futtrup and J. Candy, Speakerbench, Loudspeaker Industry Sourcebook, Feature Article (2020) 124-131.

(5) J. Candy and C. Futtrup, A Contour Integral Method for Time-Domain Response Calculations, J. Audio Eng. Soc. 66 (2018) 360

Last edited by a moderator:

Online Articles

This material has just been published online by audioxpress.com. We (Jeff and Claus) would be happy to hear your feedback about Speakerbench.

Part 1

Parameter Estimation and Box Simulation with Speakerbench (Part 1) - Model Parameter Comparisons | audioXpress

Part 2

Parameter Estimation and Box Simulation with Speakerbench (Part 2) - Introducing Speakerbench | audioXpress

This material has just been published online by audioxpress.com. We (Jeff and Claus) would be happy to hear your feedback about Speakerbench.

Part 1

Parameter Estimation and Box Simulation with Speakerbench (Part 1) - Model Parameter Comparisons | audioXpress

Part 2

Parameter Estimation and Box Simulation with Speakerbench (Part 2) - Introducing Speakerbench | audioXpress

I have just learned about Speakerbench! I have a few newbie questions to get my data collection to a higher standard, since I already have the DATS tool.

The issue is that I am getting in Model Fit is "Fit quality: SORRY :-("

so I need to do better but here is what I do.

1. Can the woofer be placed horizontally on a solid surface, on three blocks (magnet sits on block to leave vent hole open), for measurements?

2. Is DATS good enough to take measurements? Let's say I am designing a subwoofer box... And when is DATS not good enough?

Thanks!

The issue is that I am getting in Model Fit is "Fit quality: SORRY :-("

so I need to do better but here is what I do.

1. Can the woofer be placed horizontally on a solid surface, on three blocks (magnet sits on block to leave vent hole open), for measurements?

2. Is DATS good enough to take measurements? Let's say I am designing a subwoofer box... And when is DATS not good enough?

Thanks!

- Home

- Loudspeakers

- Multi-Way

- Speakerbench