This is the JBL capacitor I replaced by Clarity .

It is the 60 / 70s.

Its capacitance is correct today !!!!

Question :

It is paper in oil capacitor or paper in wax capacitor ?

I would like to know your opinions, thank you !.

It is the 60 / 70s.

Its capacitance is correct today !!!!

Question :

It is paper in oil capacitor or paper in wax capacitor ?

I would like to know your opinions, thank you !.

Attachments

Last edited:

Let's be honest boys and girls. No-one has ever found the smoking gun that says it is worth spending huge sums on capacitors!

I've heard theories of aluminium foils oxidising to a rectifying layer, suggesting that gold, silver and even tin foils are better. I've heard of capacitor squeal introducing noise. Vibration and damping effects. Enclosing capacitors in damping rubber or rigid cans.

The fact is that above and below the critical crossover region, where stress maximises, the capacitors are either all-pass or band-stop. It's like they are not there!

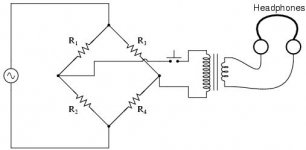

Until somebody does some sensible measurements with an old-fashioned bridge-null technique that actually compares what two different capacitors do, I'm just not going to spend money on something that reduces distortion below 0.1%. There are worse culprits in loudspeakers, and for that matter, the rest of the amplifier chain.

I've heard theories of aluminium foils oxidising to a rectifying layer, suggesting that gold, silver and even tin foils are better. I've heard of capacitor squeal introducing noise. Vibration and damping effects. Enclosing capacitors in damping rubber or rigid cans.

The fact is that above and below the critical crossover region, where stress maximises, the capacitors are either all-pass or band-stop. It's like they are not there!

Until somebody does some sensible measurements with an old-fashioned bridge-null technique that actually compares what two different capacitors do, I'm just not going to spend money on something that reduces distortion below 0.1%. There are worse culprits in loudspeakers, and for that matter, the rest of the amplifier chain.

Attachments

Keeping with the Russian cap theme, I used K73-16 PETP caps....very neutral but they bring out the detail...and they are cheap! I replaced Mundorf SIO with these caps...haven't had any desire to switch back...ymmv of course.

Polyethylene Terephthalate caps are guess what? Mylar!!

https://en.wikipedia.org/wiki/Polyethylene_terephthalate

Mylars (and I mean true DuPont Mylar, not average MKT polyester mylar) are what I use in a spot on the mids in my reference pair. Granted, my Mylars are Film/Foil, double-wound for non-inductive properties, oil-impregnated, and 1000VDC types, but still- They 'let more through' even with the slightly higher ESR, than the Clarity SA and Jantzen Silvers I was switching between.

I don't hear Solens as 'harsh', but more of a 'gritty' quality. This goes for 250V/400V/630V, and even the Silversound models. I will admit though that the Silversounds are less gritty than the basic line. Solens in shunt circuits are great though, and are my preference there.

Being that your (OP) NPE locations are likely smaller, some of the poly offerings may not even fit your application and require being mounted off-board. I prefer the Audyn Q4 to all of Bennic, Dayton, and Solen makes when it comes to series placement, and they are generally less expensive as well. BUT- when size matters, Erse PulseX, and Jantzen Satandard Z-Caps are pretty much the compact leaders.

Later,

Wolf

"No-one has ever found the smoking gun that says it is worth spending huge sums on capacitors! "

People that can't hear will save a ton of money in audio.

http://i56.photobucket.com/albums/g196/dkleitsch/Capbasics.jpg

http://i56.photobucket.com/albums/g196/dkleitsch/Capbasics2.jpg

People that can't hear will save a ton of money in audio.

http://i56.photobucket.com/albums/g196/dkleitsch/Capbasics.jpg

http://i56.photobucket.com/albums/g196/dkleitsch/Capbasics2.jpg

"No-one has ever found the smoking gun that says it is worth spending huge sums on capacitors! "

People that can't hear will save a ton of money in audio.

http://i56.photobucket.com/albums/g196/dkleitsch/Capbasics.jpg

http://i56.photobucket.com/albums/g196/dkleitsch/Capbasics2.jpg

What am I looking at, besides the very annoying popup at the lower left corner of my screen?

Polyethylene Terephthalate caps are guess what? Mylar!!

https://en.wikipedia.org/wiki/Polyethylene_terephthalate

Mylars (and I mean true DuPont Mylar, not average MKT polyester mylar) are what I use in a spot on the mids in my reference pair. Granted, my Mylars are Film/Foil, double-wound for non-inductive properties, oil-impregnated, and 1000VDC types, but still- They 'let more through' even with the slightly higher ESR, than the Clarity SA and Jantzen Silvers I was switching between.

I don't hear Solens as 'harsh', but more of a 'gritty' quality. This goes for 250V/400V/630V, and even the Silversound models. I will admit though that the Silversounds are less gritty than the basic line. Solens in shunt circuits are great though, and are my preference there.

Being that your (OP) NPE locations are likely smaller, some of the poly offerings may not even fit your application and require being mounted off-board. I prefer the Audyn Q4 to all of Bennic, Dayton, and Solen makes when it comes to series placement, and they are generally less expensive as well. BUT- when size matters, Erse PulseX, and Jantzen Satandard Z-Caps are pretty much the compact leaders.

Later,

Wolf

Thanks Wolf for seconding my cap brand recommendations in post #11.

The JBL caps were a metalized film with hand-soldered teflon wire leads, mounted in a sand-filled paper tube and sealed with wax.

They sounded pretty good, and I wouldn't replace them unless the ESR was poor.

Thanks for your answer.

But it is not clear if the film is wound in oil, wax, or both .....

Watch this capacitor, traces of oil are there.

Attachments

What am I looking at, besides the very annoying popup at the lower left corner of my screen?

Those are hysteresis plots on a oscilloscope. There is a circuit layout about how to make a jig in the recent AudioXpress, and then measure this with it.

Thanks Wolf for seconding my cap brand recommendations in post #11.

I inadvertently seconded the cap-brand recommendation, but I was much more specific about which ones.

Wolf

Interesting science here. Polyester (an oxygenated dielectric) worse than pure hydrocarbon dielectrics. As proved on the oscilloscope.

Yup, no argument there either. Electrolytics (Tantalum, aluminium with a wet electrolyte) are worse. As also proved on the oscilloscope. Particularly worse when not polarised, better in the back to back NP arrangement.

Surprisingly good result for old-fashioned foil in oiled/waxed paper types, aka PIO. People used to make their own capacitors this way.

Back in the day when I worked with 45MHz transatlantic submarine cables, the dielectric of choice for low loss was polyethylene, with aluminium outer conductor and a copper core IIRC. Copper core because these cables carried a DC current for phantom powering of the amplifiers spaced every three miles.

Polystyrene is an aromatic hydrocarbon, FWIW, but none the worse for it on these low resolution measurements.

So all that is left to decide is whether exotic polypropylene aka boutique capacitors are audibly better than the 250V cheapies. And THAT is entirely a matter for YOU!

When I calculate the ESR of the above mentioned caps the data looks:

3000 Hz; npe=0,476; mkp=0,052

In the region of our interest for a 3,3 uF cap, the difference isn't night and day.

Yup, no argument there either. Electrolytics (Tantalum, aluminium with a wet electrolyte) are worse. As also proved on the oscilloscope. Particularly worse when not polarised, better in the back to back NP arrangement.

Surprisingly good result for old-fashioned foil in oiled/waxed paper types, aka PIO. People used to make their own capacitors this way.

Back in the day when I worked with 45MHz transatlantic submarine cables, the dielectric of choice for low loss was polyethylene, with aluminium outer conductor and a copper core IIRC. Copper core because these cables carried a DC current for phantom powering of the amplifiers spaced every three miles.

Polystyrene is an aromatic hydrocarbon, FWIW, but none the worse for it on these low resolution measurements.

So all that is left to decide is whether exotic polypropylene aka boutique capacitors are audibly better than the 250V cheapies. And THAT is entirely a matter for YOU!

Attachments

Interesting science here. Polyester (an oxygenated dielectric) worse than pure hydrocarbon dielectrics. As proved on the oscilloscope.

Yup, no argument there either. Electrolytics (Tantalum, aluminium with a wet electrolyte) are worse. As also proved on the oscilloscope. Particularly worse when not polarised, better in the back to back NP arrangement.

Surprisingly good result for old-fashioned foil in oiled/waxed paper types, aka PIO. People used to make their own capacitors this way.

Back in the day when I worked with 45MHz transatlantic submarine cables, the dielectric of choice for low loss was polyethylene, with aluminium outer conductor and a copper core IIRC. Copper core because these cables carried a DC current for phantom powering of the amplifiers spaced every three miles.

Polystyrene is an aromatic hydrocarbon, FWIW, but none the worse for it on these low resolution measurements.

So all that is left to decide is whether exotic polypropylene aka boutique capacitors are audibly better than the 250V cheapies. And THAT is entirely a matter for YOU!

I remember seeing those hysteresis plots some time ago with the write up about them. Does anybody have a link to the accompanying write up? I want to know if the differences in those plots were audible with blind testing in an actual speaker application. If, OTOH, they are merely a lab exercise in the measurement of minutia, then I'm not interested.

"But it is not clear if the film is wound in oil, wax, or both .....

Watch this capacitor, traces of oil are there. "

That's hot-melt glue, not oil, and what part of "metalized film with hand-soldered teflon wire leads, mounted in a sand-filled paper tube and sealed with wax." don't you understand?

Watch this capacitor, traces of oil are there. "

That's hot-melt glue, not oil, and what part of "metalized film with hand-soldered teflon wire leads, mounted in a sand-filled paper tube and sealed with wax." don't you understand?

"But it is not clear if the film is wound in oil, wax, or both .....

Watch this capacitor, traces of oil are there. "

That's hot-melt glue, not oil, and what part of "metalized film with hand-soldered teflon wire leads, mounted in a sand-filled paper tube and sealed with wax." don't you understand?

I do not mean the epoxy glue (which always was clear, it seems that did not get along with aluminum cases such xovers vintage JBL) but the oil that comes from inside the capacitor. Do you understand me now ? I bet the value in microfarads is not correct. (This capacitor is not mine, the photo is from another forum)

I think here's some information that might be interested, I did not read it yet, but I wanted to share ..

Picking Capacitors - Walter G. Jung and Richard Marsh

Attachments

Since English is not your first language, I think it is the problem.

There is NO oil in the JBL caps.

There is NO epoxy in the JBL caps.

Please find someone that has a better grasp of English and have them explain it to you.

Do you know what a paper tube is?

Do you know what sand is?

Do you Know what wax is?

Do you know what metalized film is?

There is NO oil in the JBL caps.

There is NO epoxy in the JBL caps.

Please find someone that has a better grasp of English and have them explain it to you.

Do you know what a paper tube is?

Do you know what sand is?

Do you Know what wax is?

Do you know what metalized film is?

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Speaker crossover caps upgrade?