Hi eveyone,

I'm trying to design & build a pair of 3-way speakers, using the AJ Sealed cabinet calculator program (based on the Golden Ratio). (www.ajdesigner.com)

It asks for the Qts, Qes, Fs, Vas, PMax, diameter and Xmax of the speaker driver, leaving the Qtc for you to choose (I've read 0.707 is a good number).

For my Monacor bass drivers, it comes up with an interesting size, which I'm happy with.

But for the mid driver (which can also be used as a bass driver in a 2-way bookshelf speaker), the cabinet size it comes up with is very small, only marginally bigger than the actual driver unit!

I have all the parameters it wants from the Monacor data sheet, so I can only think that this driver needs an incredibly small cabinet.

But it seems very odd for it to be so small.

I'm going to have the mid cabinet built separately and attached to the top of the bass cabinet, and employ time alignment by having it receeded slightly (c.1 5/8 inch) back from the edge of the bass cabinet.

I used to own a pair of B&W DM-6 speakers (the 'pregnant droid' speakers!), and loved the fact that it had the mid driver recessed back from the bass, and the tweeter recessed back again from the mid driver, to achieve correct time alignment.

I thought I'd try and incorporate the same idea in my speakers. It won't do any harm in trying.

I'm using the measurements from the very back of each driver, as it's the closest I can see to measuring to the centre of the magnet, which I believe is the actual axis I should be basing such calculations on.

I've read that each side panel should be internally braced to avoid resonances.

What exactly does this look like?

Do I just glue diagonal strips of wood on each internal side?

I'm thinking of using oak plywood, as it's readily available from a local DIY store.

I've read birch veneer cabinet grade plywood is preferable, for which I'll look.

I was considering getting a brad nailer to assdist in the construction, but have read of people using wood / deck screws.

I built 2 GhettoBlasters a few years ago using the Golden Ratio, 1/2 inch oak plywood & MDF (one each), old car radio units, 6x9 speakers and car subwoofer amps & drivers.

I used deck screws for the construction, along with carpenter's glue, but found it very time consuming drilling all the pilot then clearance holes, and thought that if professionally built cabinets are constructed using staples / nails, then surely it must be just as good as screws and much faster..?

They sound great, by the way, which is why I'm attempting this speaker build.

The speakers with be 3-way, and will be matched to a Bassworks 2x12 front ported car subwoofer cabinet featuring 2 x 12 inch SSL "1000w" speaker drivers.

I had this running via a QSC amp recently, via a Clean Box Pro -10 to +4 dB converter, from my 2.1 stereo amp, and it sounds incredible!

So, it'll be a 4-way actively crossed over system, using a dbx DriveRack 260 speaker management system, feeding into 3 Yamaha Natural Sound stereo amps plus the QSC sub amp.

The dbx will give me stereo top & stereo mid, then mono-summed bass and mono-summed sub-bass at line level.

The Yamaha amps and Monacor drivers (all the tweeters, squakers & woofers are Monacor, to keep the sound consistent) are matched for power output / input, and all the Yamaha amps are identical (to keep the sound consistent).

My aim is to combine my experience of working with PA sound rigs, studio monitor sound systems, car and home audio Hi-Fi speaker technology and create a hybrid sound system.

I want, not just a 3-way speaker (which is a rarity in domestic Hi-Fi, and why I loved my DM-6s so much), but an ACTIVELY crossed-over time-aligned 3-way speaker, using the advantages of PA technology, then adding it to a deep and powerful sub-bass speaker unit.

The potential is quite breathtaking.

My very own personal Hi-Fi PA theatre studio monitor system.

If nothing else, it'll be a fascinating experiment into all of the fields mentioned.

And judging from my GhettoBlasters, there's every chance the system will sound pretty impressive.

Going for sealed cabinet / infinate baffle seems to give a big margin of error, and hopefully a nice, warm quality bass sound.

The Bassworks sub-bass cabinet has dealt with the ported aspect, so I don't have to consider it for the main speakers.

I know there's a lot going on here, and probably many areas of concern / issue for many of you out there.

Don't worry. I know it's a totally mad idea. But why not? It'll be a laugh! And could sound great!

I just need a bit of advice in the design of the mid cabinets and the general construction of the bass & mid cabs (the tweeters will reside above the mids in the same cabinet, but sealed off so their internal volumes don't affect each other).

I've found my Canadian Tire mitre & table saws aren't very accurate, so cutting consistently is a bit hard.

I've tried using my circular saw using a metal ruler clamped down as a straight edge guide, but this too has its issues with accuracy.

I've had no wood-working / carpentry training, and have taught myself the skills so far. Maybe not very well..!

Any advice is greatly appreciated!

Many thanks in advance - Dave

I'm trying to design & build a pair of 3-way speakers, using the AJ Sealed cabinet calculator program (based on the Golden Ratio). (www.ajdesigner.com)

It asks for the Qts, Qes, Fs, Vas, PMax, diameter and Xmax of the speaker driver, leaving the Qtc for you to choose (I've read 0.707 is a good number).

For my Monacor bass drivers, it comes up with an interesting size, which I'm happy with.

But for the mid driver (which can also be used as a bass driver in a 2-way bookshelf speaker), the cabinet size it comes up with is very small, only marginally bigger than the actual driver unit!

I have all the parameters it wants from the Monacor data sheet, so I can only think that this driver needs an incredibly small cabinet.

But it seems very odd for it to be so small.

I'm going to have the mid cabinet built separately and attached to the top of the bass cabinet, and employ time alignment by having it receeded slightly (c.1 5/8 inch) back from the edge of the bass cabinet.

I used to own a pair of B&W DM-6 speakers (the 'pregnant droid' speakers!), and loved the fact that it had the mid driver recessed back from the bass, and the tweeter recessed back again from the mid driver, to achieve correct time alignment.

I thought I'd try and incorporate the same idea in my speakers. It won't do any harm in trying.

I'm using the measurements from the very back of each driver, as it's the closest I can see to measuring to the centre of the magnet, which I believe is the actual axis I should be basing such calculations on.

I've read that each side panel should be internally braced to avoid resonances.

What exactly does this look like?

Do I just glue diagonal strips of wood on each internal side?

I'm thinking of using oak plywood, as it's readily available from a local DIY store.

I've read birch veneer cabinet grade plywood is preferable, for which I'll look.

I was considering getting a brad nailer to assdist in the construction, but have read of people using wood / deck screws.

I built 2 GhettoBlasters a few years ago using the Golden Ratio, 1/2 inch oak plywood & MDF (one each), old car radio units, 6x9 speakers and car subwoofer amps & drivers.

I used deck screws for the construction, along with carpenter's glue, but found it very time consuming drilling all the pilot then clearance holes, and thought that if professionally built cabinets are constructed using staples / nails, then surely it must be just as good as screws and much faster..?

They sound great, by the way, which is why I'm attempting this speaker build.

The speakers with be 3-way, and will be matched to a Bassworks 2x12 front ported car subwoofer cabinet featuring 2 x 12 inch SSL "1000w" speaker drivers.

I had this running via a QSC amp recently, via a Clean Box Pro -10 to +4 dB converter, from my 2.1 stereo amp, and it sounds incredible!

So, it'll be a 4-way actively crossed over system, using a dbx DriveRack 260 speaker management system, feeding into 3 Yamaha Natural Sound stereo amps plus the QSC sub amp.

The dbx will give me stereo top & stereo mid, then mono-summed bass and mono-summed sub-bass at line level.

The Yamaha amps and Monacor drivers (all the tweeters, squakers & woofers are Monacor, to keep the sound consistent) are matched for power output / input, and all the Yamaha amps are identical (to keep the sound consistent).

My aim is to combine my experience of working with PA sound rigs, studio monitor sound systems, car and home audio Hi-Fi speaker technology and create a hybrid sound system.

I want, not just a 3-way speaker (which is a rarity in domestic Hi-Fi, and why I loved my DM-6s so much), but an ACTIVELY crossed-over time-aligned 3-way speaker, using the advantages of PA technology, then adding it to a deep and powerful sub-bass speaker unit.

The potential is quite breathtaking.

My very own personal Hi-Fi PA theatre studio monitor system.

If nothing else, it'll be a fascinating experiment into all of the fields mentioned.

And judging from my GhettoBlasters, there's every chance the system will sound pretty impressive.

Going for sealed cabinet / infinate baffle seems to give a big margin of error, and hopefully a nice, warm quality bass sound.

The Bassworks sub-bass cabinet has dealt with the ported aspect, so I don't have to consider it for the main speakers.

I know there's a lot going on here, and probably many areas of concern / issue for many of you out there.

Don't worry. I know it's a totally mad idea. But why not? It'll be a laugh! And could sound great!

I just need a bit of advice in the design of the mid cabinets and the general construction of the bass & mid cabs (the tweeters will reside above the mids in the same cabinet, but sealed off so their internal volumes don't affect each other).

I've found my Canadian Tire mitre & table saws aren't very accurate, so cutting consistently is a bit hard.

I've tried using my circular saw using a metal ruler clamped down as a straight edge guide, but this too has its issues with accuracy.

I've had no wood-working / carpentry training, and have taught myself the skills so far. Maybe not very well..!

Any advice is greatly appreciated!

Many thanks in advance - Dave

Sounds interesting.

As for the cabinet material I've attached an article, penned by a prominent designer, which details a composite of two different materials. I'm not suggesting you necessarily follow his choices, but consider alternatives: plywood and MDF, plywood and (gasp) chipboard. Whether the plywood is birch oak or walnut veneered is irrelevant. What counts is the number of layers (more the better) and the lack of voids. Baltic Birch is great, but more expensive. I've got a pair of 75 litre cabinets made with panels of 3/4" 'shop' birch ply (Google Rona for 'shop' birch) with 1/4" OSB glued to it. They are inert.

As for bracing, strips fastened along the vertical dimension are the most effective. Use at least one per side, and depending on dimensions, one or two on the back baffle.

Frankly, there's no reason you can't use a brad nailer (the Ryobi 1, 18v, nailers are great and don't require a compressor) with GLUE. You don't need exotic glue, ordinary PVA (white glue) is more than capable.

As for accurate cuts .... I don't know where you are in Canada but most lumber yards/stores will provide a cutting service for a nominal fee. A competent employee should be able to provide accurate cuts following your dimensions. An alternative would be to contact a millwork shop and ask them to provide you with accurate panels. The millwork shop should also be able to accurately rout the speaker holes.

As for your midrange, making a larger cabinet won't be an issue. More critical is to ensure your dimensions are not constant to reduce standing waves. IOW, not 5 x 5 x5 ... You can stuff it with polyfill, and even leave the back open (as Troels Gravesen admitted liking) if you prefer, as with a proper crossover the mid will never be driven anywhere near its resonance.

As for the cabinet material I've attached an article, penned by a prominent designer, which details a composite of two different materials. I'm not suggesting you necessarily follow his choices, but consider alternatives: plywood and MDF, plywood and (gasp) chipboard. Whether the plywood is birch oak or walnut veneered is irrelevant. What counts is the number of layers (more the better) and the lack of voids. Baltic Birch is great, but more expensive. I've got a pair of 75 litre cabinets made with panels of 3/4" 'shop' birch ply (Google Rona for 'shop' birch) with 1/4" OSB glued to it. They are inert.

As for bracing, strips fastened along the vertical dimension are the most effective. Use at least one per side, and depending on dimensions, one or two on the back baffle.

Frankly, there's no reason you can't use a brad nailer (the Ryobi 1, 18v, nailers are great and don't require a compressor) with GLUE. You don't need exotic glue, ordinary PVA (white glue) is more than capable.

As for accurate cuts .... I don't know where you are in Canada but most lumber yards/stores will provide a cutting service for a nominal fee. A competent employee should be able to provide accurate cuts following your dimensions. An alternative would be to contact a millwork shop and ask them to provide you with accurate panels. The millwork shop should also be able to accurately rout the speaker holes.

As for your midrange, making a larger cabinet won't be an issue. More critical is to ensure your dimensions are not constant to reduce standing waves. IOW, not 5 x 5 x5 ... You can stuff it with polyfill, and even leave the back open (as Troels Gravesen admitted liking) if you prefer, as with a proper crossover the mid will never be driven anywhere near its resonance.

Attachments

It didn't take very long to figure out my crappy tire portable table saw is, wait for it......crappy. 😆I've found my Canadian Tire mitre & table saws aren't very accurate, so cutting consistently is a bit hard.

BTW, nothing beats a CNC router.

jeff

How exactly should internal braces be made / positioned / attached?

What sort of material / thickness / shape should be used?

What sort of material / thickness / shape should be used?

I guess some of that depends on what you have, or can access. I use a dense wood, so hardwood of some kind, or Douglas fir, 3/4" wide and 1 1/2" deep. (Yes, I know we're metric, and I can think in kilometers and litres, as well as Celsius, but I still can't visualize something expressed in millimeters). As stated, run them vertically. The point being to create smaller sections which would resonate at a higher frequency. You could also place a horizontal strap connected to the side braces, tying them together. Depending on the dimensions of your front and rear baffles, and the placement of your driver's, you might find a way to connect your vertical back brace to the front baffle.

If you look online you'll no doubt see some speaker porn where the builder has gone into immaculate detail on inner braces. I don't see the point. As long as you fasten things flush, and glued, it's good. As a reference, the craftsmen who built heirloom pieces hundreds of years ago didn't give a damn what the back of pieces looked like, as long as they obeyed the rule that solid wood moves. (A rule you can ignore with plywood, MDF, OSB, etc.)

If you look online you'll no doubt see some speaker porn where the builder has gone into immaculate detail on inner braces. I don't see the point. As long as you fasten things flush, and glued, it's good. As a reference, the craftsmen who built heirloom pieces hundreds of years ago didn't give a damn what the back of pieces looked like, as long as they obeyed the rule that solid wood moves. (A rule you can ignore with plywood, MDF, OSB, etc.)

OK, thanks for that info.

So any side braces would be placed in the middle of the side in question, vertically, reaching from very bottom to very top..?

I was thinking of using 1/2" ply as it would be easier to work, and I saw some guy on YouTube showing that 3/4" ply / MDF offers minimal, if any, decrease in undesirable resonances when compared to 1/2".

As my 1/2" GhettoBlasters are already heavy, and it was hard enough to cut the 1/2" (especially the MDF), 3/4" doesn't seem attractive to me.

Maybe I'm wrong.

I was thinking of maybe using 3/4" for the front (speaker) baffle sides only, so as to act as reinforcement for the speakers' energy.

The AJ calculator gives me a box of dimensions 6" x 9 5/8" x 3 5/8" for my 5 1/4" Monacor SPH-135KEP bass-mid speaker.

I entered all the specific data fields it asked for, using Qtc of 0.707, yet the box is only marginally larger than the driver itself!

The very rear of the driver is only 3/4" away from the rear baffle.

Why would they give such tight dimensions?

Could it be that, using the figures from Monacor, this speaker actually does need a really small box to function as intended..?

Would having a really small box help in acting as a far stronger dampener, keeping the driver much more tightly 'held' by the internal air pressure, and thus give a tighter sound to higher frequencies, as it would restrict the larger movements that relate to lower frequencies..?

The calculator gives a far larger, spaceous box for the Monacor SPH-250KE bass driver, so there must be something in the figures Monacor are providing for the SPH-135KEP that's making the calculator suggest such a small box for it...

I'm not viewing the Golden Ratio / AJ Box calculator as the diffinative & only way to proceed, but I think could be a good starting basis since it asks for so many driver specific specs, it should be pretty close to the ideal box for that given speaker.

So any side braces would be placed in the middle of the side in question, vertically, reaching from very bottom to very top..?

I was thinking of using 1/2" ply as it would be easier to work, and I saw some guy on YouTube showing that 3/4" ply / MDF offers minimal, if any, decrease in undesirable resonances when compared to 1/2".

As my 1/2" GhettoBlasters are already heavy, and it was hard enough to cut the 1/2" (especially the MDF), 3/4" doesn't seem attractive to me.

Maybe I'm wrong.

I was thinking of maybe using 3/4" for the front (speaker) baffle sides only, so as to act as reinforcement for the speakers' energy.

The AJ calculator gives me a box of dimensions 6" x 9 5/8" x 3 5/8" for my 5 1/4" Monacor SPH-135KEP bass-mid speaker.

I entered all the specific data fields it asked for, using Qtc of 0.707, yet the box is only marginally larger than the driver itself!

The very rear of the driver is only 3/4" away from the rear baffle.

Why would they give such tight dimensions?

Could it be that, using the figures from Monacor, this speaker actually does need a really small box to function as intended..?

Would having a really small box help in acting as a far stronger dampener, keeping the driver much more tightly 'held' by the internal air pressure, and thus give a tighter sound to higher frequencies, as it would restrict the larger movements that relate to lower frequencies..?

The calculator gives a far larger, spaceous box for the Monacor SPH-250KE bass driver, so there must be something in the figures Monacor are providing for the SPH-135KEP that's making the calculator suggest such a small box for it...

I'm not viewing the Golden Ratio / AJ Box calculator as the diffinative & only way to proceed, but I think could be a good starting basis since it asks for so many driver specific specs, it should be pretty close to the ideal box for that given speaker.

So any side braces would be placed in the middle of the side in question, vertically, reaching from very bottom to very top..?

Yes

How large is your bass box?

What is the crossover frequency between your woofer and mid and what's the FS of the mid.

I'm not at all familiar with AJ Box calculator. Do you have access to Excel on a Windows computer - unfortunately there's enough difference 'tween the Mac and Windows version of Excel that you need Windows. If you have that, I can link to a very good cabinet calculator, or you can search for 'Unibox408'.

Yes

How large is your bass box?

What is the crossover frequency between your woofer and mid and what's the FS of the mid.

I'm not at all familiar with AJ Box calculator. Do you have access to Excel on a Windows computer - unfortunately there's enough difference 'tween the Mac and Windows version of Excel that you need Windows. If you have that, I can link to a very good cabinet calculator, or you can search for 'Unibox408'.

Two weak points on inexpensive table saws are usually low power and crappy fences.

A high quality, sharp blade with an appropriate tooth count will help greatly. They're a bit spendy but I use a Forrest Woodworker II and swear by them.

You can trade off convenience for improved accuracy with a homemade fence, clamped fore and aft after careful measurement. Its always a good idea to cut all of the pieces of the same width before moving the fence and that goes double for one clamped in place.

Good luck, be safe and have fun

A high quality, sharp blade with an appropriate tooth count will help greatly. They're a bit spendy but I use a Forrest Woodworker II and swear by them.

You can trade off convenience for improved accuracy with a homemade fence, clamped fore and aft after careful measurement. Its always a good idea to cut all of the pieces of the same width before moving the fence and that goes double for one clamped in place.

Good luck, be safe and have fun

Thanks for the suggestions.

The bass box is 11 1/2" x 19" x 30".

The crossover frequency between the woofer & squaker can ve varied within the active crossover device, but I was thinking of around 250 Hz..?

(Sub to bass: 80Hz; Bass to mid:250Hz; Mid to hi: 4 kHz)

The mid's FS is 45 Hz.

I run Windows and have Excel, but it's via Office 2003, so might not be compatible with a newer Excel file.

Please send me any links to cabinet calculators!

I've contacted a couple of local Millworks shops and they say they can do speaker CNCing, and often do such.

They've asked for drawings & dimensions, which I need to write up.

One says one of their employees regualrly does speakers, and they've recommended a 5/8" plywood for the job.

I could be getting closer..!

The bass box is 11 1/2" x 19" x 30".

The crossover frequency between the woofer & squaker can ve varied within the active crossover device, but I was thinking of around 250 Hz..?

(Sub to bass: 80Hz; Bass to mid:250Hz; Mid to hi: 4 kHz)

The mid's FS is 45 Hz.

I run Windows and have Excel, but it's via Office 2003, so might not be compatible with a newer Excel file.

Please send me any links to cabinet calculators!

I've contacted a couple of local Millworks shops and they say they can do speaker CNCing, and often do such.

They've asked for drawings & dimensions, which I need to write up.

One says one of their employees regualrly does speakers, and they've recommended a 5/8" plywood for the job.

I could be getting closer..!

I'm thinking of using oak plywood, as it's readily available from a local DIY store.

I've read birch veneer cabinet grade plywood is preferable, for which I'll look.

In general the more plies the better the plywood. Quality can vary. Chinese & Russian Baltic Birch in our experience can be a mess. Birch, poplar, whatever…

I've read that each side panel should be internally braced to avoid resonances.

What exactly does this look like?

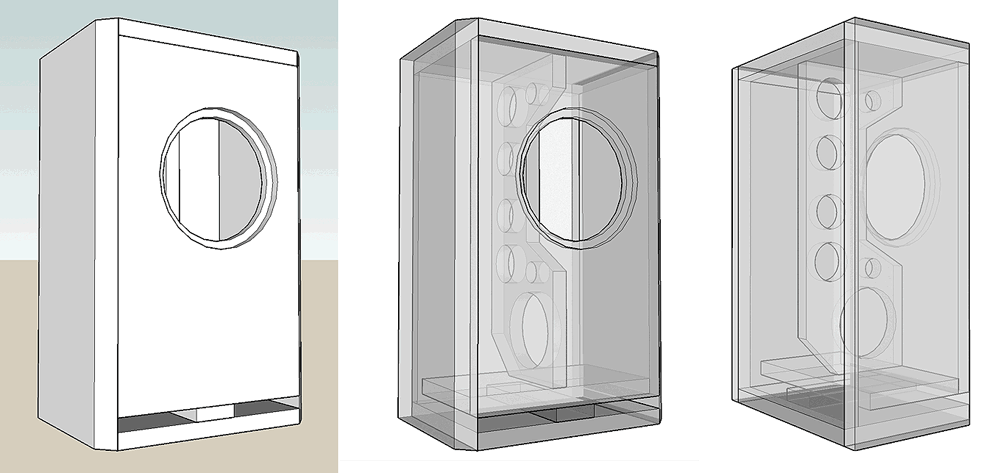

One of my CGRs.

dave

I've attached an article, penned by a prominent designer,

A guy who designs a lot of stuff. For a lot of brands (most or all part of a conglomerate, He has to have a bunch of help.

But his designs are cost constrained.

This works AFAIK, but i use a fairly simple recipe that works.

hardwood of some kind, or Douglas fir,

If you are going to work with solids you need to know what yoiuare doing.bAll these buiklt by Bernie.

Dense is not a requirement, stiff is (and preferably light). The 3rd one in is Western Red Cedar, very stiff, very light, a pair weighed less a single one made on Oak. It does easily ding. Pine is also not that dense.

Douglas Fir (a pine) with Walnut accents.

dave

I was thinking of using 1/2" ply as it would be easier to work

….

AJ calculator gives me a box of dimensions 6” x 9 5/8" x 3 5/8" for my 5 1/4" Monacor SPH-135KEP

I’d not trust that calculator. About 5 litres. Sealed it is a midrange, Might be able to get something out of it vented.

12mm is harder to work with than 15mm which we used many lifts of. But 12mm will work fine for that volume. Above about 15-20 litres we’d probably switch to 18mm.

Small box, brace driver to back shoulkd be sufficient,

To calculate a GR, take the cube root of the volume. That isone dimension. Take that number and divide byn and miultiple by ɸ ≈ 1.618 to get rthe other dimensions,

ie 5 litre = 5,000 cm3 -> cube root =17 cm. 17 x 1.618 = 27.5, 17 ÷ 1.618 = 10.5

So 17 x 27.5 x 10.5 cm

dave

Last edited:

The enclosure volume only affects the frequency and step response around resonance frequency (fc, driver in sealed enclosure).but I was thinking of around 250 Hz..?

I guess you will cross the midrange (far?) above fc, so midrange chamber size is mostly irrelevant, can be bigger than suggested for qtc=0.707. Just make sure to stuff it completely with damping material.

This is more likely to work on an older Excel, than a newer version.

http://audio.claub.net/software/kougaard/ubdwnld.html

http://audio.claub.net/software/kougaard/ubdwnld.html

Wow!

Some great responses here!

Planet 10: those are beautful speakers there! I love the deep wood colour and the trapeziod shapes!

That cross-section drawing showing the internal brace: wow!

It's bracing the top, bottom, front & back all at the same time, as far as I can see..!

Very clever design, and I love the swerve cutout at the front to facilitate the driver unit!

Very gorgeous designs!

I'm not aiming for such beauty here, as it's my first attempt at the main speakers, and something of an experiment.

If it goes well, I could try to incorporate such features in any subsequent speakers, most likely portable sound system / PA speakers.

For this, I'm trying to keep things simple / cost effective.

The Millworks shops have said their prices are related to the number of cuts they have to make, so the more elaborate the design, the more it will cost.

What is this 'GR' you speak of..?

Cube root of which volume..? The potential speaker's? The driver's Vas?

Like what Prarieboy said, we're metric for sure, but I've found for carpentry stuff, feet & inches are an easier number to work with.

Mind you, I'm sure the Millworks shops' computers can work with millimetres.

If the Vas of the bass-mid speaker is 15.5L, then dimension X=(cube root of 15,500=24.933cm=)25cm, Y=40.45cm, Z=15.45cm

The AJ calculator gets the same for X & Z dimensions (give or take), but puts Y at only 9.28cm, so it's basing its calculations on Z (15.45cm), then going up 1.618 & down 1.618, instead of X. Interesting...

Some great responses here!

Planet 10: those are beautful speakers there! I love the deep wood colour and the trapeziod shapes!

That cross-section drawing showing the internal brace: wow!

It's bracing the top, bottom, front & back all at the same time, as far as I can see..!

Very clever design, and I love the swerve cutout at the front to facilitate the driver unit!

Very gorgeous designs!

I'm not aiming for such beauty here, as it's my first attempt at the main speakers, and something of an experiment.

If it goes well, I could try to incorporate such features in any subsequent speakers, most likely portable sound system / PA speakers.

For this, I'm trying to keep things simple / cost effective.

The Millworks shops have said their prices are related to the number of cuts they have to make, so the more elaborate the design, the more it will cost.

What is this 'GR' you speak of..?

Cube root of which volume..? The potential speaker's? The driver's Vas?

Like what Prarieboy said, we're metric for sure, but I've found for carpentry stuff, feet & inches are an easier number to work with.

Mind you, I'm sure the Millworks shops' computers can work with millimetres.

If the Vas of the bass-mid speaker is 15.5L, then dimension X=(cube root of 15,500=24.933cm=)25cm, Y=40.45cm, Z=15.45cm

The AJ calculator gets the same for X & Z dimensions (give or take), but puts Y at only 9.28cm, so it's basing its calculations on Z (15.45cm), then going up 1.618 & down 1.618, instead of X. Interesting...

If I used this cube root system of the Vas with the bass speaker (Vas = 204L), I'd get:

X=59cm, Y=95cm & Z= 36.5cm

So, one dimension would be almost a metre..!

So, either I'm not understanding how to use this calculation properly, or it has similar problems as the AJ calculator, except in the opposite direction!

What fun!

Just as well I'm not designing rocket engines or X-ray machines..!

X=59cm, Y=95cm & Z= 36.5cm

So, one dimension would be almost a metre..!

So, either I'm not understanding how to use this calculation properly, or it has similar problems as the AJ calculator, except in the opposite direction!

What fun!

Just as well I'm not designing rocket engines or X-ray machines..!

bracing the top, bottom, front & back all at the same time

thse and the baffle create an i-beamish structure, Very strong and stiff for the amount material used. It also spreads the reactive energy of the driver to more parts of the box. In the case of the CGR the sides have such short span it is almost as if the baffle is as thick as the box is deep.

dabe

ɸ

CGR = Classic Golden Ratio.

Golden Ratio = ɸ = 1.618…

The volume is the volume of the box. To find this you use a sealed box calculator, input Vas, Fs, Qts and choose a Q. Usually for hifi one chooses 0.5 to just under 1. Q = 0.707 = Butterworth is max flat. Adding the stuffing lowrs the Q (ie effectively increasing the size off the box (a bit).

dave

What is this 'GR' you speak of..?

Cube root of which volume..? The potential speaker's? The driver's Vas?

CGR = Classic Golden Ratio.

Golden Ratio = ɸ = 1.618…

The volume is the volume of the box. To find this you use a sealed box calculator, input Vas, Fs, Qts and choose a Q. Usually for hifi one chooses 0.5 to just under 1. Q = 0.707 = Butterworth is max flat. Adding the stuffing lowrs the Q (ie effectively increasing the size off the box (a bit).

dave

OK, Dave, which box calculator would you suggest?

So far, I've tried the AJ Sealed box calculator and am about to try Prarieboy's link to Unibox 4.08.

I've just opened it, and immediately get an error message saying Macros are disabled.

I'm not sure if that will be a problem, I'll give it a try...

So far, I've tried the AJ Sealed box calculator and am about to try Prarieboy's link to Unibox 4.08.

I've just opened it, and immediately get an error message saying Macros are disabled.

I'm not sure if that will be a problem, I'll give it a try...

- Home

- Design & Build

- Construction Tips

- Speaker build: any suggestions?