I am currently looking for a power supply for a Sonic Impact amp. I was thinking of a 13.8 supply unit but I dont know how much current it should deliver. I have the choice of 2 A and 4 A units. Is the 2 A unit sufficient? More precisely, it delivers 2 A steadily and can go up to 4 A in peaks (the 4 A unit goes up to 6 A in peaks).

Thanks for your advice.

Mick

Thanks for your advice.

Mick

Hallo Mick ,

2A reichen normalerweise aus, aber 4A können auf keinen Fall schaden .

Mein T-Amp hängt an einem Voltkraft 16A ! mit 0,5 Farad Auto Cap .

Ist super mit dem T-Amp , aber ein klein wenig Overkill .

Grüße von Bruchsal (die Spargelstadt) nach Köln !

Jürgen

2A reichen normalerweise aus, aber 4A können auf keinen Fall schaden .

Mein T-Amp hängt an einem Voltkraft 16A ! mit 0,5 Farad Auto Cap .

Ist super mit dem T-Amp , aber ein klein wenig Overkill .

Grüße von Bruchsal (die Spargelstadt) nach Köln !

Jürgen

I tried the T-amp with an analog lab power supply and I made the observation that it plays with a lot more drive and rhythmization when a heavy current limit is used.

Oliver

Oliver

Power supply question

Mick_F

The SI is rated to 15 watts per ch. into 4 ohms. This is about 2.7 amps total but remember that this is at 10% distortion so heavily into clipping. A more realistic value would be 11 watts @ 1% dist. This is still into clipping but only slightly. Playing music takes much less power than test signals and I have run one of these units quite successfully with a 1.25 A supply and a large reservoir cap (22,000uf) to take care of the peaks. I would think you would be quite happy with the smaller supply as long as you also use a large auxiliary cap.

Try both and let us know your impressions.

Roger

Mick_F

The SI is rated to 15 watts per ch. into 4 ohms. This is about 2.7 amps total but remember that this is at 10% distortion so heavily into clipping. A more realistic value would be 11 watts @ 1% dist. This is still into clipping but only slightly. Playing music takes much less power than test signals and I have run one of these units quite successfully with a 1.25 A supply and a large reservoir cap (22,000uf) to take care of the peaks. I would think you would be quite happy with the smaller supply as long as you also use a large auxiliary cap.

Try both and let us know your impressions.

Roger

Unfortunately my power supply doesn`t go below 100mA, so I can`t say exactly where it sounds best.

Thanks for your advice.

Using an adjustable lab power supply is a good idea. I can borrow one so I will try that too.

I will also exchange the caps. Is there any illustrated description availabe on the web showing the location of the caps to be exchanged?

Sorry for these questions, which most probably have been discussed extensively already....

Mick

Using an adjustable lab power supply is a good idea. I can borrow one so I will try that too.

I will also exchange the caps. Is there any illustrated description availabe on the web showing the location of the caps to be exchanged?

Sorry for these questions, which most probably have been discussed extensively already....

Mick

Is there any illustrated description availabe on the web showing the location of the caps to be exchanged?

Here

(And associated links)

Re: Power supply question

I agree, and use of these 2A 12V Parts Express 120-536 supplies to power the SI for my computer speakers.

http://www.partsexpress.com/pe/showdetl.cfm?&DID=7&Partnumber=120-536

They are linear regulated units, with a fairly heavy transformer, At $15. it is a good deal. This, with a big cap(s), will beat the crap out of any wallwart and also the regulation will make sure you don't fry the SI amp with overvoltage.

Bob

sx881663 said:Mick_F

Playing music takes much less power than test signals and I have run one of these units quite successfully with a 1.25 A supply and a large reservoir cap (22,000uf) to take care of the peaks. I would think you would be quite happy with the smaller supply as long as you also use a large auxiliary cap.

Roger

I agree, and use of these 2A 12V Parts Express 120-536 supplies to power the SI for my computer speakers.

http://www.partsexpress.com/pe/showdetl.cfm?&DID=7&Partnumber=120-536

They are linear regulated units, with a fairly heavy transformer, At $15. it is a good deal. This, with a big cap(s), will beat the crap out of any wallwart and also the regulation will make sure you don't fry the SI amp with overvoltage.

Bob

I just listened to Stravinsky`s Sacre and I find that even heavy bassdrum attacks sound better with 100mA limit.

I just tried a trimmer in series instead of the active current limit. Almost same result, but not very practicable, because you have to correct the trimmer at any volume change. I adjusted the trimmer up to 70 Ohm, dependent on the volume.

Sonic signature

I am not sure what it is you are doing but it defiantly is adding some sonic signature into the amp that you apparently like. Sounds like dynamic compression would be the main component. If you really prefer this sound it begs the question, what other fault is it covering up? This is all too subjective to comment further on.

Roger

el`Ol said:I just listened to Stravinsky`s Sacre and I find that even heavy bassdrum attacks sound better with 100mA limit.

I am not sure what it is you are doing but it defiantly is adding some sonic signature into the amp that you apparently like. Sounds like dynamic compression would be the main component. If you really prefer this sound it begs the question, what other fault is it covering up? This is all too subjective to comment further on.

Roger

Re: Sonic signature

Maybe it covers the fault that the sonic behaviour of the tripath chip is too different for different levels.

sx881663 said:

Sounds like dynamic compression would be the main component. If you really prefer this sound it begs the question, what other fault is it covering up?

Roger

Maybe it covers the fault that the sonic behaviour of the tripath chip is too different for different levels.

Some have the SI boards without the solder-made heat slug. If you find your chip is getting too hot, that might explain degradation with higher currents.

I ended up adding the solder to mine, after which the backside of the PCB certainly does get warmer. I hesitate to recommend adding the solder because (due to the volume of solder) there is an inherant risk to it, especially if one didn't limit how long or hot the 2024 chip gets during the procedure. Also it's worth noting that due to the 'sinking grid extending past the chip itself, solder can easily pool on the top (inverted) side of the PCB before all the holes are completely saturated.

I ended up adding the solder to mine, after which the backside of the PCB certainly does get warmer. I hesitate to recommend adding the solder because (due to the volume of solder) there is an inherant risk to it, especially if one didn't limit how long or hot the 2024 chip gets during the procedure. Also it's worth noting that due to the 'sinking grid extending past the chip itself, solder can easily pool on the top (inverted) side of the PCB before all the holes are completely saturated.

! said:Some have the SI boards without the solder-made heat slug. If you find your chip is getting too hot, that might explain degradation with higher currents.

I ended up adding the solder to mine, after which the backside of the PCB certainly does get warmer. I hesitate to recommend adding the solder because (due to the volume of solder) there is an inherant risk to it, especially if one didn't limit how long or hot the 2024 chip gets during the procedure. Also it's worth noting that due to the 'sinking grid extending past the chip itself, solder can easily pool on the top (inverted) side of the PCB before all the holes are completely saturated.

I agree this is risky. I have done one successfully but in sections at different times with a temp controlled iron (Metcal soldering station). Don't think I would do another as it seems like more risk than its worth. There has been talk of sliding a thin strip of copper foil under it. Guess this would help as long as it was anchored well away from any active circuits that it could short out. Another possible solution that comes to mind would be to squirt some heat sink compound through the holes on the back side. With enough, it would have to help some. I am not sure all of the available compounds are totally nonconductive though.

Roger

The problem I saw with alternate heat-sinking solutions was that the SI's 2024 was just barely not touching the gridwork- perhaps it was in a few tiny elevated regions, and perhaps there is minor variation in this from one product specimen to the next.

Anyway, I'm not so sure that sliding anything under there would go very well, that if it were thick, it may not make a great contact, but if thin, it might even buckle a bit while being slid in.

Thermal epoxy might work, but since it's fairly viscous and the chip pretty close to the PCB, it could be quite tedious filling in the holes in passes as the epoxy sets, taking multiple passes to complete, plus it may not make very good contact and already being an inferior heat conductor- there's no turning back if it doesn't get the job done well enough, nor anyway to be certain the epoxy is wicking all the way towards the chip like solder should.

I did also solder it in multiple passes, allowing the chip to cool some inbetween each. I contemplated then taking a larger iron and quickly heating the whole mass for a uniform shape then decided the minimal esthetic gain wasn't worth the risk.

Anyway, I'm not so sure that sliding anything under there would go very well, that if it were thick, it may not make a great contact, but if thin, it might even buckle a bit while being slid in.

Thermal epoxy might work, but since it's fairly viscous and the chip pretty close to the PCB, it could be quite tedious filling in the holes in passes as the epoxy sets, taking multiple passes to complete, plus it may not make very good contact and already being an inferior heat conductor- there's no turning back if it doesn't get the job done well enough, nor anyway to be certain the epoxy is wicking all the way towards the chip like solder should.

I did also solder it in multiple passes, allowing the chip to cool some inbetween each. I contemplated then taking a larger iron and quickly heating the whole mass for a uniform shape then decided the minimal esthetic gain wasn't worth the risk.

I tried the T-amp with an analog lab power supply and I made the observation that it plays with a lot more drive and rhythmization when a heavy current limit is used.

Hello Oliver,

You said this and then later went on to mention specific current limits. I would very much like to understand what is going on here. Are you saying that it sounds better if you limit the amount of current that the power supply can deliver? Do you use a current limiter to do this?

Thanks,

Dave

I use the current limit knob on my power supply. When you concentrate you realize that there is also a slight improvement on 8Ohm speakers with the poti at twelve o`clock.

I found out that the sensitivity declaration of the 8-Ohmers I used for testing wasn`t correct. Maybe for high sensitivity 8Ohm speakers the current limit is essential as well.

I found out that the sensitivity declaration of the 8-Ohmers I used for testing wasn`t correct. Maybe for high sensitivity 8Ohm speakers the current limit is essential as well.

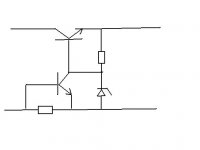

el`Ol said:I use the current limit knob on my power supply.

Okay, good. Technically, what does the current limit knob do? Is it a potentiometer in the power line? does it control the DC voltage as well as the current?

Dave

- Status

- Not open for further replies.

- Home

- Amplifiers

- Class D

- Sonic Impact PSU current