Hi Everyone,

I've been occupying myself lately with some aspects in speakers upgrades/rejuvenates. Cables and connectors are on the table for quite some time.

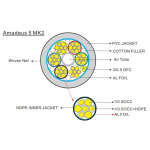

It is maybe well known, I came across RAMM AUDIO AMADEUS 5 MK2 Speaker Cable

Floored, just floored...

But that cable is not the object of the topic.

Today, l came across the description of some banana plugs. As the common material is some brass, or copper, there has been always a shadow over the springy effect of the tip (at least to me). Neither brass nor Cu would retain their shape once squished (Elastic vs Plastic Deformation), thus the contact will degrade even after the first use. This doesn't happen, or at least noticeably.

The description of the material of the tip of the banana plugs (under question) was stated as "ferromanganese", Bingo->steel just steel.

I pulled out the sets of banana plugs I have, various brands, sources, models. ALL of them react to my test magnet....

Floored again. The realization that connectors introduce ferromagnetism within the signal path hit me badly. (beeng on the path of "pure" sound I have replaced all steel nuts, and else on the binding posts with brass ones)

Is the ferromagnetism a real issue, plus, the much resistance added, or I'm getting paranoid?

Now what?

Are spades the only option (Cu), Shrapnel Type , or/and straight wire to terminal connections.

Thx

I've been occupying myself lately with some aspects in speakers upgrades/rejuvenates. Cables and connectors are on the table for quite some time.

It is maybe well known, I came across RAMM AUDIO AMADEUS 5 MK2 Speaker Cable

Floored, just floored...

But that cable is not the object of the topic.

Today, l came across the description of some banana plugs. As the common material is some brass, or copper, there has been always a shadow over the springy effect of the tip (at least to me). Neither brass nor Cu would retain their shape once squished (Elastic vs Plastic Deformation), thus the contact will degrade even after the first use. This doesn't happen, or at least noticeably.

The description of the material of the tip of the banana plugs (under question) was stated as "ferromanganese", Bingo->steel just steel.

I pulled out the sets of banana plugs I have, various brands, sources, models. ALL of them react to my test magnet....

Floored again. The realization that connectors introduce ferromagnetism within the signal path hit me badly. (beeng on the path of "pure" sound I have replaced all steel nuts, and else on the binding posts with brass ones)

Is the ferromagnetism a real issue, plus, the much resistance added, or I'm getting paranoid?

Now what?

Are spades the only option (Cu), Shrapnel Type , or/and straight wire to terminal connections.

Thx

Attachments

Last edited:

or I'm getting paranoid?

Perhaps.

If you consider that the component leads in amplifiers these days are likely to have a steel core, then at what point do you stop worrying about non-linear magnetic behaviour?

Sure, applying some physics, passing electrons through a ferrous material can create a magnetic field, introducing some hysteresis as the field collapses and gives back to the signal at a later time stamp. Question is, how much is needed for an audible manifestation and what is that manifestation. I know Danny Ritchie is big on this and mentions "smearing" the signal but until one can actually determine a measurement that quantifies the effect and magnitude, it is all theorycrafting. Not to say that it is wrong but it is unverified and science loves verification.

re:'Danny Ritchie is big on this and mentions "smearing" - sounds like marketing bs to me, as does 'connectors introduce ferromagnetism within the signal path'.

Re:'the much resistance added' - how much?, ever measured the resistance of a 1" steel bolt?

Re:'the much resistance added' - how much?, ever measured the resistance of a 1" steel bolt?

I use straight wire. Twist. Solder the twist with fair amount of silver bearing solder. Done.straight wire to terminal connections.

I'm no metallurgist so take this for what it's worth. I've never heard of a perfect material and the 3rd law of thermodynamics would point to none. silver or copper are best for conducting but oxidize fairly easily. Gold is used most often for corrosion prevention and it is a decent conductor but not the best and fairly malleable. Structurally, steel is good stuff but it is ferrous. Brass seems to get some amount of love but will still corrode, just less so as copper.What would be the perfect material for a speaker connector?

As some have pointed out, best connection is a straight run of wire soldered at the amp signal board output pads and the crossover input but the convenience factor is crap.

In their power amplifier books, both Bob Cordell and Douglas Self demonstrate increased distortion at speaker outputs when iron is introduced in the speaker wiring either through relays or brass coated steel speaker terminals.

How audible this is I have no idea, but you clearly would avoid this in a commercial product.

Most of my home brew electronics use TH components that have steel leads. Would it sound even better if they didn’t? Again no clue, but it isn’t something I will lose sleep over.

I managed to get over my initial horror at finding this out 😀.

How audible this is I have no idea, but you clearly would avoid this in a commercial product.

Most of my home brew electronics use TH components that have steel leads. Would it sound even better if they didn’t? Again no clue, but it isn’t something I will lose sleep over.

I managed to get over my initial horror at finding this out 😀.

Then, what is the purpose of "space" cables and else if the signal leaves the amp /originates distorted and enters the speakers after another distortion?

Would the two distortions cancel each other and the signal gets "clean"? lol

Would the two distortions cancel each other and the signal gets "clean"? lol

Wire size is about voltage drop over distance, so whichever is lower is considered 'cleanest' by industrial standards. Type, connection depends on the needs of the app with single strand cold welds the best type, connection.

In an ideal environment ordinary wire is fine. If, however, you live in a high EM area, such as any city, then I prefer coaxial speaker cables. Comparing a pal's spaced wires with a homebrew coax setup (4 RG-8U, all cores in parallel, all shields in parallel) showed the coax had "less" highs, but returning to the wires showed their extra highs were trash. Strapping in the coax again sounded, for lack of a better word, cleaner, with a blacker background. Conversely, there was much less effect when trying the cables at an exurban location.

The working hypothesis is radio frequency interference returning to the power amp negative feedback input and intermodulating with the audio.

The working hypothesis is radio frequency interference returning to the power amp negative feedback input and intermodulating with the audio.

My advise - get a friend and 2 good switches and do some tests. Normal wire, very good wire. The friend switches.

You can put anything between the switches, use 10m of wire to amplify the effect!

When you clearly hear the effect - continue the search.

When not - get Speakons as they have the lowest contact resistivity and are reliable for years.

You can put anything between the switches, use 10m of wire to amplify the effect!

When you clearly hear the effect - continue the search.

When not - get Speakons as they have the lowest contact resistivity and are reliable for years.

Yeah, I live across the highway from one of the South's busiest small jet ports and on the (relatively low) flight paths of both Atlanta Intl. with all manner of large/jumbo airliners and Dobbins AFB with multiple C5G delivering supplies around the globe (near?) daily, so run grounding wires from everything electronic to my cold water pipe and rock salt coated telephone/internet in ground grounding system rather than relying on the house's rather meager (in comparison) UL grounding system.In an ideal environment ordinary wire is fine. If, however, you live in a high EM area, such as any city, then I prefer coaxial speaker cables.

The working hypothesis is radio frequency interference returning to the power amp negative feedback input and intermodulating with the audio.

I don't have any comment or opinion about various connectors.As the common material is some brass, or copper, there has been always a shadow over the springy effect of the tip (at least to me). Neither brass nor Cu would retain their shape once squished (Elastic vs Plastic Deformation), thus the contact will degrade even after the first use. This doesn't happen, or at least noticeably.

But I do want to point out that there are some grades of copper based alloys (brass and bronze) which have a high yield strength, and which can be used for springs and other parts which must deflect and return to the original shape. So it should be possible to make a banana plug from a copper alloy.

Yes, there are, rather exotic alloys, with much higher resistance evidently.But I do want to point out that there are some grades of copper based alloys (brass and bronze) which have a high yield strength, and which can be used for springs and other parts which must deflect and return to the original shape. So it should be possible to make a banana plug from a copper alloy.

For the record, I received today a batch of inexpensive plugs, heavy and non-magnetic. (to my utmost wonder)....

- Home

- Loudspeakers

- Multi-Way

- Some thought on speaker connectors...