Here are some pictures of my solid cherry & walnut MTM build.

You are not supposed to build a speaker out of solid wood because of crossgrain wood movement.

All the wood grain in this speaker goes the same way.

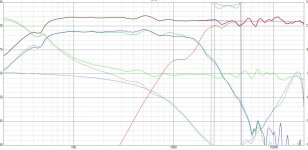

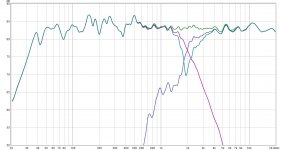

Drivers are a pair of custom Seas 6-1/2″ L18RNX/P based Prestige 4Ω Woofers and a Morel Morel MDT-40 1-1/8" Compact Dome Tweeter.

Crossover is at 1900Hz.

You are not supposed to build a speaker out of solid wood because of crossgrain wood movement.

All the wood grain in this speaker goes the same way.

Drivers are a pair of custom Seas 6-1/2″ L18RNX/P based Prestige 4Ω Woofers and a Morel Morel MDT-40 1-1/8" Compact Dome Tweeter.

Crossover is at 1900Hz.

Attachments

-

1 pile of walnut and cherry.jpg144.3 KB · Views: 771

1 pile of walnut and cherry.jpg144.3 KB · Views: 771 -

10 cherry sides rough crosscut.jpg168.4 KB · Views: 162

10 cherry sides rough crosscut.jpg168.4 KB · Views: 162 -

9 walnut dressed blanks.jpg151.5 KB · Views: 175

9 walnut dressed blanks.jpg151.5 KB · Views: 175 -

8 walnut glued blanks.jpg167.8 KB · Views: 188

8 walnut glued blanks.jpg167.8 KB · Views: 188 -

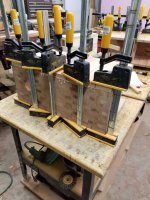

7 starting walnut baffle glueup.jpg190.2 KB · Views: 196

7 starting walnut baffle glueup.jpg190.2 KB · Views: 196 -

6 walnut strips dressed.jpg147.1 KB · Views: 161

6 walnut strips dressed.jpg147.1 KB · Views: 161 -

5 walnut ripped.jpg148.3 KB · Views: 745

5 walnut ripped.jpg148.3 KB · Views: 745 -

4 walnut front baffle rough.jpg164.2 KB · Views: 757

4 walnut front baffle rough.jpg164.2 KB · Views: 757 -

3 tops and bottoms glueup.jpg175.7 KB · Views: 779

3 tops and bottoms glueup.jpg175.7 KB · Views: 779 -

2 high tech layout.jpg114.9 KB · Views: 773

2 high tech layout.jpg114.9 KB · Views: 773

more pics...

Attachments

-

20 backs covered in glue.jpg176.5 KB · Views: 224

20 backs covered in glue.jpg176.5 KB · Views: 224 -

19 baffle glueup.jpg142 KB · Views: 248

19 baffle glueup.jpg142 KB · Views: 248 -

18 baffle strips.jpg150.4 KB · Views: 239

18 baffle strips.jpg150.4 KB · Views: 239 -

17 back glueup.jpg139.2 KB · Views: 184

17 back glueup.jpg139.2 KB · Views: 184 -

16 cherry stips for speaker back.jpg172.5 KB · Views: 163

16 cherry stips for speaker back.jpg172.5 KB · Views: 163 -

15 crosscutting back cherry baffle.jpg175.7 KB · Views: 159

15 crosscutting back cherry baffle.jpg175.7 KB · Views: 159 -

14 large pile of panels.jpg155.1 KB · Views: 153

14 large pile of panels.jpg155.1 KB · Views: 153 -

13 cherry backs blank.jpg144.2 KB · Views: 177

13 cherry backs blank.jpg144.2 KB · Views: 177 -

12 cherry sides double width.jpg166.5 KB · Views: 166

12 cherry sides double width.jpg166.5 KB · Views: 166 -

11 cherry sides glueup 1.jpg184.9 KB · Views: 168

11 cherry sides glueup 1.jpg184.9 KB · Views: 168

more pics 2...

Attachments

-

27 brace glued in.jpg172.9 KB · Views: 174

27 brace glued in.jpg172.9 KB · Views: 174 -

28 gluing sides.jpg151.8 KB · Views: 151

28 gluing sides.jpg151.8 KB · Views: 151 -

29 glueing side.jpg164.2 KB · Views: 158

29 glueing side.jpg164.2 KB · Views: 158 -

30 gluing side back.jpg169.9 KB · Views: 173

30 gluing side back.jpg169.9 KB · Views: 173 -

26 test fit back.jpg147.5 KB · Views: 199

26 test fit back.jpg147.5 KB · Views: 199 -

25 test fit joinery.jpg150 KB · Views: 175

25 test fit joinery.jpg150 KB · Views: 175 -

24 biscuits and dominos.jpg156.8 KB · Views: 163

24 biscuits and dominos.jpg156.8 KB · Views: 163 -

23 laying out box parts for glueup.jpg143.2 KB · Views: 158

23 laying out box parts for glueup.jpg143.2 KB · Views: 158 -

22 front and back surfaced.jpg137.7 KB · Views: 186

22 front and back surfaced.jpg137.7 KB · Views: 186 -

21 baffle glued up.jpg151.6 KB · Views: 220

21 baffle glued up.jpg151.6 KB · Views: 220

more pics 3...

Attachments

-

40 laying out drivers on baffle.jpg139.6 KB · Views: 271

40 laying out drivers on baffle.jpg139.6 KB · Views: 271 -

39 baffes slightly oversized.jpg146 KB · Views: 323

39 baffes slightly oversized.jpg146 KB · Views: 323 -

37 everything flush and sanded.jpg171.6 KB · Views: 266

37 everything flush and sanded.jpg171.6 KB · Views: 266 -

36 lapping front of boxes on giant sanding block so perfectly flat.jpg143.7 KB · Views: 242

36 lapping front of boxes on giant sanding block so perfectly flat.jpg143.7 KB · Views: 242 -

35 boxes glued up.jpg141.6 KB · Views: 241

35 boxes glued up.jpg141.6 KB · Views: 241 -

34 glueing top on.jpg163.9 KB · Views: 193

34 glueing top on.jpg163.9 KB · Views: 193 -

33 biscuits for top and bottom.jpg150.7 KB · Views: 180

33 biscuits for top and bottom.jpg150.7 KB · Views: 180 -

32 back planed flush with sides.jpg86.7 KB · Views: 171

32 back planed flush with sides.jpg86.7 KB · Views: 171 -

31 back slightly larger than sides for cleanup.jpg64.3 KB · Views: 190

31 back slightly larger than sides for cleanup.jpg64.3 KB · Views: 190

More Pics. ..

Attachments

-

50 flats for woofer tt nuts.jpg92.8 KB · Views: 241

50 flats for woofer tt nuts.jpg92.8 KB · Views: 241 -

49 drilling flats for woofer tee nuts.jpg113.5 KB · Views: 248

49 drilling flats for woofer tee nuts.jpg113.5 KB · Views: 248 -

48 screws to hold teenuts.jpg97.5 KB · Views: 294

48 screws to hold teenuts.jpg97.5 KB · Views: 294 -

47 test fit drivers.jpg136.1 KB · Views: 279

47 test fit drivers.jpg136.1 KB · Views: 279 -

46 releif for back of woofer.jpg102.8 KB · Views: 250

46 releif for back of woofer.jpg102.8 KB · Views: 250 -

45 drilling for tweeter.jpg158.1 KB · Views: 198

45 drilling for tweeter.jpg158.1 KB · Views: 198 -

44 rebate for tweeter.jpg118.9 KB · Views: 215

44 rebate for tweeter.jpg118.9 KB · Views: 215 -

43 rebates done.jpg159.8 KB · Views: 212

43 rebates done.jpg159.8 KB · Views: 212 -

42 starting rebates for drivers.jpg158.8 KB · Views: 198

42 starting rebates for drivers.jpg158.8 KB · Views: 198 -

41 good start hole for driver cutout circle jig.jpg118.9 KB · Views: 219

41 good start hole for driver cutout circle jig.jpg118.9 KB · Views: 219

Yeah more pics, brilliant job, great detail and accuracy.

Just one question, what would you charge to build these for fellow members ?

Just one question, what would you charge to build these for fellow members ?

Agreed keep them comming 😛... imagine giving those baby's their first oilReally nice! Don't stop with the photos...

More pics . .. .

Attachments

-

57 box all sanded.jpg134.7 KB · Views: 182

57 box all sanded.jpg134.7 KB · Views: 182 -

58 now for a little roundover.jpg113.9 KB · Views: 194

58 now for a little roundover.jpg113.9 KB · Views: 194 -

59 roundovers done.jpg104.8 KB · Views: 220

59 roundovers done.jpg104.8 KB · Views: 220 -

60 boxes finished.jpg142.4 KB · Views: 374

60 boxes finished.jpg142.4 KB · Views: 374 -

56 flush trimming baffles.jpg94.2 KB · Views: 180

56 flush trimming baffles.jpg94.2 KB · Views: 180 -

55 gluing baffles on.jpg174 KB · Views: 199

55 gluing baffles on.jpg174 KB · Views: 199 -

54 rebated baffle on box.jpg114.4 KB · Views: 207

54 rebated baffle on box.jpg114.4 KB · Views: 207 -

53 rebating baffle to fit on box 2.jpg156.8 KB · Views: 183

53 rebating baffle to fit on box 2.jpg156.8 KB · Views: 183 -

52 rebating baffle to fit on box.jpg182.1 KB · Views: 204

52 rebating baffle to fit on box.jpg182.1 KB · Views: 204 -

51 woofer tee nuts in.jpg120.7 KB · Views: 242

51 woofer tee nuts in.jpg120.7 KB · Views: 242

Amazing! More pics of the wood finishing, please! What did you use there? Danish oil or something similar?

That is stunningly beautiful. I can't even imagine the craftsmanship and skills

required to do something like that.

More pics when you have them please. 🙂

required to do something like that.

More pics when you have them please. 🙂

Amazing! More pics of the wood finishing, please! What did you use there? Danish oil or something similar?

For a finish I use a 1:1:1 mix of satin oil based polyurethane:boiled linseed oil:turpentine. Brush on, leave for 30 min to an hour depending on heat and humidity, wipe off. Speakers got two coats inside, three coats outside. This is a finish for dummies. Super easy to do. Just make sure you dispose of the rags correctly by burning them or hanging them to dry, otherwise they could self combust (I am serious about this!).

Here are some final pics...

Attachments

-

woof 1.jpg84.5 KB · Views: 243

woof 1.jpg84.5 KB · Views: 243 -

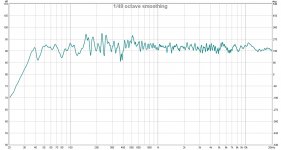

1 68 final seas morel freq response.jpg127.6 KB · Views: 301

1 68 final seas morel freq response.jpg127.6 KB · Views: 301 -

1 67 - final 3.jpg454.1 KB · Views: 335

1 67 - final 3.jpg454.1 KB · Views: 335 -

1 66 - final 1.jpg543.4 KB · Views: 348

1 66 - final 1.jpg543.4 KB · Views: 348 -

1 65 - final 1.jpg525.8 KB · Views: 426

1 65 - final 1.jpg525.8 KB · Views: 426 -

64 - crossovers in.jpg117.1 KB · Views: 422

64 - crossovers in.jpg117.1 KB · Views: 422 -

63 - boxes stuffed.jpg118.1 KB · Views: 423

63 - boxes stuffed.jpg118.1 KB · Views: 423 -

62 - crossovers done.jpg162.7 KB · Views: 436

62 - crossovers done.jpg162.7 KB · Views: 436 -

61 boxes finished 2.jpg167.7 KB · Views: 425

61 boxes finished 2.jpg167.7 KB · Views: 425 -

four measurements dec 7.jpg121.6 KB · Views: 235

four measurements dec 7.jpg121.6 KB · Views: 235

Are those real measurements? If so, how did you make them? What kind of room? What microphone did you use?

Are those real measurements? If so, how did you make them? What kind of room? What microphone did you use?

Hello,

Yes, those are all real measurements. I used a UMIK-1 and REW for the measurements.

They were all taken at about 25" on axis to the tweeter.

For crossover purposes the woofer was also measured at 1/4" and merged with the 25" measurement, baffle step compensation was added with,

FRD Blender and Minimum Phase Extractor

My living room, which is a good size room.

David.

This is what happens when a craftsman builds speakers 😀 Not only will audiophiles admire your speakers, but others' furniture will envy it as well 😀

Hello,

Yes, those are all real measurements. I used a UMIK-1 and REW for the measurements.

They were all taken at about 25" on axis to the tweeter.

For crossover purposes the woofer was also measured at 1/4" and merged with the 25" measurement, baffle step compensation was added with,

FRD Blender and Minimum Phase Extractor

My living room, which is a good size room.

David.

Interesting. I would have expected a much less flat response when taking the measurements in a normal room but perhaps that's the applied smoothing.

Well done!

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Some pics of my Solid Cherry & Walnut MTM build