A fellow once told me to remove any gasket between the driver and cabinet as an inexpensive sound improvement. Here, I'd like to explore the opposite - deliberately decoupling a driver from the cab using a soft cushion. Almost always, the driver frame is hard-fastened to the baffle. What happens when you change the mechanical character of that attachment?

So I have some really bad cabinets with no internal framing nor braces - just cheap, 1/2" MDF glued together at the edges. They ring badly and have never sounded good to me. Rather than throwing them away, they may lend themselves to this kind of experiment.

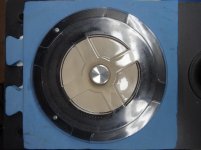

So what to do? Take a first shot at it. I had a couple pieces of "foam" - the kind that clip together to make a soft play floor for a kid. So I cut holes in the baffle to accommodate T-nuts with the idea being I want the foam to isolate the mounting fasteners from the baffle wood, by any degree possible. See photos below.

I'm not particularly good at building anything and I barely made it with clearance between the T-nuts and the baffle wood - it however shows the idea of what I'm trying to attain. A rap test about the driver frame with a screwdriver handle indicates "FAIL", as the clunk of the basket seems to well radiate through the foam and into the enclosure wood panels. It even makes different tones about the radius, corresponding to the 4 struts left from the T-nut clearance hole cutouts.

I suppose if I used something like Sorbothane, I might get a better result. That stuff being worth its weight in Gold, (because it works for audiophile TT isolation) probably a couple 8" square 1/2" thick sheets arent within the realm of a possible investment for experimenting. I do have some less stiff material (from an inexpensive yoga mat) on hand. Any suggestions of an effective material I can try?

I'm pre-supposing that decoupling a cheap cabinet design from the driver trumps giving the driver a solid mechanical ground to push against, in terms of how the whole system will sound. The measurement techniques in the "accel for cabinet panel resonance" thread could be used to validate any effect, by building one with soft decoupling and one with hard coupling to the baffle.

So I have some really bad cabinets with no internal framing nor braces - just cheap, 1/2" MDF glued together at the edges. They ring badly and have never sounded good to me. Rather than throwing them away, they may lend themselves to this kind of experiment.

So what to do? Take a first shot at it. I had a couple pieces of "foam" - the kind that clip together to make a soft play floor for a kid. So I cut holes in the baffle to accommodate T-nuts with the idea being I want the foam to isolate the mounting fasteners from the baffle wood, by any degree possible. See photos below.

I'm not particularly good at building anything and I barely made it with clearance between the T-nuts and the baffle wood - it however shows the idea of what I'm trying to attain. A rap test about the driver frame with a screwdriver handle indicates "FAIL", as the clunk of the basket seems to well radiate through the foam and into the enclosure wood panels. It even makes different tones about the radius, corresponding to the 4 struts left from the T-nut clearance hole cutouts.

I suppose if I used something like Sorbothane, I might get a better result. That stuff being worth its weight in Gold, (because it works for audiophile TT isolation) probably a couple 8" square 1/2" thick sheets arent within the realm of a possible investment for experimenting. I do have some less stiff material (from an inexpensive yoga mat) on hand. Any suggestions of an effective material I can try?

I'm pre-supposing that decoupling a cheap cabinet design from the driver trumps giving the driver a solid mechanical ground to push against, in terms of how the whole system will sound. The measurement techniques in the "accel for cabinet panel resonance" thread could be used to validate any effect, by building one with soft decoupling and one with hard coupling to the baffle.

Attachments

Last edited:

Hi Joe,

Decoupling the driver is a good thing, and sorbothane is a good material for doing this. But instead of bolting the drivers into something soft, think about mounting/fixing the driver by magnet, or to clamp it softly between a brace and the front baffle. Both will work fine and will reduce vibration transfer into the box and baffle. A thing to keep in mind is the weight ratio when you´re doing this. A small driver, let´s say a 5" widerange with Mms of 6 grams and a total weight of 2000 grams - just an example - will work fine softly fixed, a larger bass driver might require additional weight attached to the magnet.

All the best

Mattes

Decoupling the driver is a good thing, and sorbothane is a good material for doing this. But instead of bolting the drivers into something soft, think about mounting/fixing the driver by magnet, or to clamp it softly between a brace and the front baffle. Both will work fine and will reduce vibration transfer into the box and baffle. A thing to keep in mind is the weight ratio when you´re doing this. A small driver, let´s say a 5" widerange with Mms of 6 grams and a total weight of 2000 grams - just an example - will work fine softly fixed, a larger bass driver might require additional weight attached to the magnet.

All the best

Mattes

I to wonder why this simple idea hasn't been used more through the decades.

It's well known that the cabinet coupled to the driver is the biggest contributor to cabinet colouration and resonances.

The second is sound returning from reflection to the cone and interfering with the sound being produced. This is both through air but also through the cabinet.

These two factors would be significantly attenuated with heavy driver damping at the coupling point to the cabinet.

It's well known that the cabinet coupled to the driver is the biggest contributor to cabinet colouration and resonances.

The second is sound returning from reflection to the cone and interfering with the sound being produced. This is both through air but also through the cabinet.

These two factors would be significantly attenuated with heavy driver damping at the coupling point to the cabinet.

With soft mounting all that will happen is speaker will move in opposite direction to cone and lose volume.

So you turn it up to make up for it and get the same vibration you got without the soft mounting.

I would be looking at gluing wooden batons to inside of cabinet.

So you turn it up to make up for it and get the same vibration you got without the soft mounting.

I would be looking at gluing wooden batons to inside of cabinet.

Really? The mass of the cone and the air it pushes is far lower than the basket and magnet.

You might have a point with low frequencies and a really floppy baffle.

But what we are discussing here is basically a carefully constructed mechanical crossover. Like the linkage between the big cone and voice coil in a whizzer FR driver.

IE. you’d get damping of the higher frequencies but cabinet support for the lower that might have amplitude to move the support structure of the driver.

You might have a point with low frequencies and a really floppy baffle.

But what we are discussing here is basically a carefully constructed mechanical crossover. Like the linkage between the big cone and voice coil in a whizzer FR driver.

IE. you’d get damping of the higher frequencies but cabinet support for the lower that might have amplitude to move the support structure of the driver.

While the cone weighs little, the compressing of the air in front of the cone puts a large force in the opposite direction.

I to wonder why this simple idea hasn't been used more through the decades.

Sony did this way back in the day. They had an aluminum inner frame, and coupled all the drivers to it. The cabinet was only used for back wave separation. I think Stereophile had covered this model in some detail.

With soft mounting all that will happen is speaker will move in opposite direction to cone and lose volume.

The idea is not to let the driver float, but rather affix it to a different structure than is used for control over its wavefront. A baffle on a wooden box does both, and there is some merit in exploring separation of energy emitted by the cone and by the frame.

I think some modern speaker manufacturers (Genelec comes to mind) have also used a single screw mounted to the driver magnet, with the brace held to the rear of the enclosure. Using Epoxy and some spare wood, a DIY version of this wouldn't be too complicated.

I'd recommend doing something like the BBC Ls3/5a cabinets, with a soft ( neoprene, foam or cork ) between the front baffle and box. I used a similar construction ( the front baffle is held on by tension springs, and there's a pair of square steel rods behind each front baffle to stiffen an damp it - the cork gasket being wide enough to separate bars/baffle) on my traffic light speakers that use four full range drivers, three used for bass and mids, the forth full range with boosted treble. Sound sublime. I'd also recommend you look for " mid range experiment... " by Remlab in the multi way section.

Gentleman, I appreciate the encouragement.

I too have thought of the stick-to-the-cabinet-back-wall driver mounting arrangement - and while at it, not just an ordinary wood stick, but one with a sorbothane (or other material) damper in it along the way. Sealing the driver basket to the front baffle then becomes another matter, where perhaps a less expensive material could be employed, such as butyl rubber sheet.

Of course, if very close tolerances between the driver basket edge and the baffle cutout edge could be kept, the rubber ring seal could be thin enough to not be flapping about due to pressure inside the cabinet. I'm sure there's an optimum for the width of this ring, allowing the driver to "float" on the post or X frame attached to the magnet.

I'm sure there is a Goldilocks Zone between the "duro" of a sorbothane puck perhaps attached to the driver magnet and the thickness / width dimensions for a rubber seal. Because the mass of the driver is now suspended on a damped spring, it's going to have a resonance - which hopefully could be engineered to be out of the way. There's a good application for an accelerometer measurement.

I'd think the bass speaker in a multiway could still be hard fastened to the cabinet baffle, as it wouldnt excite the cabinet at offending frequencies. That relieves it from this kind of treatment. I put the idea here in "full range" because in all cases, the driver may excite the cabinet at offending frequencies, thus the speaker perhaps could benefit from such an idea - particularly one with a cheaply constructed cabinet.

I'm guessing something like an Onken is almost a "box within a box", where the reflex port is cleverly distributed around the periphery of the baffle. A more complex cabinet to build, with super stiff sidewalls as a result of that effort.

I too have thought of the stick-to-the-cabinet-back-wall driver mounting arrangement - and while at it, not just an ordinary wood stick, but one with a sorbothane (or other material) damper in it along the way. Sealing the driver basket to the front baffle then becomes another matter, where perhaps a less expensive material could be employed, such as butyl rubber sheet.

Of course, if very close tolerances between the driver basket edge and the baffle cutout edge could be kept, the rubber ring seal could be thin enough to not be flapping about due to pressure inside the cabinet. I'm sure there's an optimum for the width of this ring, allowing the driver to "float" on the post or X frame attached to the magnet.

I'm sure there is a Goldilocks Zone between the "duro" of a sorbothane puck perhaps attached to the driver magnet and the thickness / width dimensions for a rubber seal. Because the mass of the driver is now suspended on a damped spring, it's going to have a resonance - which hopefully could be engineered to be out of the way. There's a good application for an accelerometer measurement.

I'd think the bass speaker in a multiway could still be hard fastened to the cabinet baffle, as it wouldnt excite the cabinet at offending frequencies. That relieves it from this kind of treatment. I put the idea here in "full range" because in all cases, the driver may excite the cabinet at offending frequencies, thus the speaker perhaps could benefit from such an idea - particularly one with a cheaply constructed cabinet.

I'm guessing something like an Onken is almost a "box within a box", where the reflex port is cleverly distributed around the periphery of the baffle. A more complex cabinet to build, with super stiff sidewalls as a result of that effort.

Last edited:

I to wonder why this simple idea hasn't been used more through the decades.

Because it does not work if you have a well built and designed enclosure.

dave

I too have thought of the stick-to-the-cabinet-back-wall driver mounting arrangement

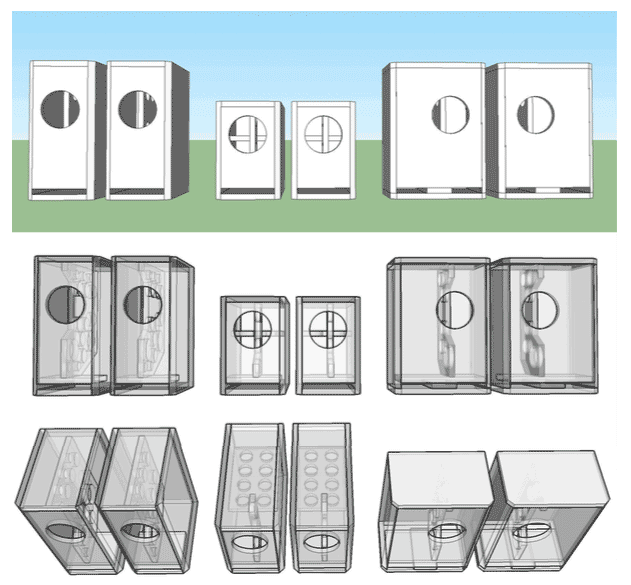

The idea of which we have taken our boxes to a more refined execution. Driver is rigidly coupled to at least 3 more box panels so as to distribute the reactive force across more panels loading less energy into the panels.

Here the 1st visualaization i found:

Anything squishy degrades the affect.

dave

If only the driver moves in reaction to the cone moving air, then it will move further than if the cone is trying to move the entire box. This degrades the reproduction of very small signals as they get buried in the much greater driver movement.

dave

dave

The idea of which we have taken our boxes to a more refined execution. Driver is rigidly coupled to at least 3 more box panels so as to distribute the reactive force across more panels loading less energy into the panels.

Anything squishy degrades the affect.

dave

Any problems with seasonal expansion and contraction of the cabinet putting too much pressure on the magnet-driver-basket-baffle, and also conversely too little pressure to render the driver bracing ineffective?

Last edited:

Because it does not work if you have a well built and designed enclosure.

dave

That sounds dangerously close to “just because”.

Is there some literature and research I should be reading?

You could say the driver cone itself is a system of this kind.

This also reminds me of the problem of suspending the exciter in a BMR speaker.

Should it just be allowed to “hang” and flop in the breeze, or should it be put on a frame structure?

I can’t imagine why it wouldn’t be a good idea to hold the driver firmly with a non resonant structure by the basket or magnet. And then let the driver rest lightly on an air pressure tight felt gasket or similar damping material?.

Any problems with seasonal expansion and contraction of the cabinet putting too much pressure on the magnet-driver-basket-baffle, and also conversely too little pressure to render the driver bracing ineffective?

Not with the plywood we use.

dave

I can’t imagine why it wouldn’t be a good idea to hold the driver firmly with a non resonant structure by the basket or magnet. And then let the driver rest lightly on an air pressure tight felt gasket or similar damping material?.

That is a solution. Eclipse does that quite well. But i put that into a too much effort required for too little, if any, gain.

If you are talking an OB it becomes simplier. But without at least 3 other walls to brace again as there is only a baffle.

dave

Why does the driver need to be held firmly, wouldn't any reactionary movement merely reduce output?I can’t imagine why it wouldn’t be a good idea to hold the driver firmly with a non resonant structure by the basket or magnet. And then let the driver rest lightly on an air pressure tight felt gasket or similar damping material?.

- Home

- Loudspeakers

- Full Range

- Softly coupling a driver to the cabinet