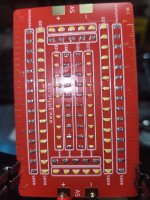

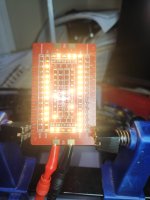

A few years back I inherited an SMD rework station, so I bought cheap little practice kit from amazon, https://www.amazon.com/Gikfun-Components-Practice-Training-Beginner/dp/B01HI6TVTE?ref_=ast_sto_dp, I thought I should at least try to learn how! Ended up with

some bridges on the chips to fix, but boy, those 0402 resistors are small, had to hold my breath! Using a chipquik syringe, no intstructions or anything with the kit, have to start some where though.

some bridges on the chips to fix, but boy, those 0402 resistors are small, had to hold my breath! Using a chipquik syringe, no intstructions or anything with the kit, have to start some where though.

I applaud you for making forward progress with the practice boards. I need to step forward on this too, instead of watching the world zip by me.

SMT was not intended for hand assembly, so whatever method works for you is the right method.

But use thin solder and lots of flux. Also desoldering braid.

But use thin solder and lots of flux. Also desoldering braid.

The braid was already deployed on the chips for solder bridges. Thankfully, not all smt is flea sized.

What does the rework station look like? There are some good ones and some that are more difficult to use.

Also, besides the stuff @rayma already mentioned, a good pair of tweezers can be of great help. Aven is a good brand. I like the #7 curved tip style myself; easier on the wrist. Titanium ones cost more but the benefit is they are nonmagnetic.

Also, besides the stuff @rayma already mentioned, a good pair of tweezers can be of great help. Aven is a good brand. I like the #7 curved tip style myself; easier on the wrist. Titanium ones cost more but the benefit is they are nonmagnetic.

I find the most important tool is a non-magnetic pair of tweezers. Mine is made from titanium. They're not cheap, but their tips don't bend and components don't stick to them. https://www.techni-tool.com/categor...-Tools/Tweezers/Swiss-High-Precision-Tweezers

I'm considering getting a vacuum pen for larger components that the tweezers won't grab.

If you have the option, use solder paste applied through a stencil rather than wire solder. I would also avoid using extra flux unless absolutely necessary.

Tom

I'm considering getting a vacuum pen for larger components that the tweezers won't grab.

If you have the option, use solder paste applied through a stencil rather than wire solder. I would also avoid using extra flux unless absolutely necessary.

Tom

Chipquik syringe, and a nameless 852d+ station. I have decent angled tweezers, but nothing fancy. The hot air station seems to be doing it's job, but I'm not very good on my end yet. This project is an $8 practice kit, no stencil. A real project I would definitely like a stencil. I blew it on the 402 resistors, they are about the size of a flea, and I used too much paste.

Following encouragement from @Markw4 I also bought couple of kits. Got nowhere good without tweezers! So bought tweezers and some finer solder and can now solder 0805 and 0603s. Floor Monster is a hazard. I’ve pinged a couple of components out of the tweezers never to be seen again 😦. I still haven’t got the knack of those little resistor arrays on the edge of the board. My solder is much too big still, I need a much finer solder.

I don’t have a hot air station and I haven’t tried paste yet. I need a lot more practice before I get anywhere near a real circuit, but I’m closer than I was!

I am pretty much much at the limit with my illuminated bench magnifier, not sure I’ll be able to do anything with 0402s as they really are incredibly tiny!

I’ll shall persevere, but I might need to spend some money on better tools.

Jeff.

I don’t have a hot air station and I haven’t tried paste yet. I need a lot more practice before I get anywhere near a real circuit, but I’m closer than I was!

I am pretty much much at the limit with my illuminated bench magnifier, not sure I’ll be able to do anything with 0402s as they really are incredibly tiny!

I’ll shall persevere, but I might need to spend some money on better tools.

Jeff.

Why I dread the most about SMT is the last component that ends up ruining a nearly finished board.

Also, even when you produce something that looks good, you don’t quite know if it is good, unless the board makes it easy to test.

Solder paste and heat gun can feel magical at times.

Also, even when you produce something that looks good, you don’t quite know if it is good, unless the board makes it easy to test.

Solder paste and heat gun can feel magical at times.

I have a Hakko vacuum pen, and also a Chinese fish tank vacuum pick. Don't like either one. They are very sensitive to the angle the vacuum pick is brought into contact with the IC. Any air leakage tends to be a problem with reliable pickup. Also, its easy for parts to fall loose when trying to fine position them. For bigger parts where the suction cups can be used its a little better, but once parts are that big its usually easier for me to pick them up with my fingers. I can hold down one side with a finger and solder a pin or two on the other side to get it tacked down.

All the other Hakko products I have are very good. Only the vacuum pick turned out to be not that useful. A friend came over to try it out too; same conclusions from him.

- Home

- Design & Build

- Equipment & Tools

- SMT Soldering