Hi, it's a while since I've posted on this forum but I would really appreciate some opinions from other experienced engineers on this one please if possible...

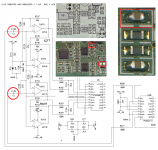

Attached are high quality photos and schematics of the circuit in question.

The outputs from the PGA2311 DCAVC are AC coupled to the inputs of the next stage via 2 x 1uF SMT ceramic caps. The legend on the schematic is incorrect, they are non-polarised caps.

One has been removed and measured. I believe they are not NP0/C0G types, or indeed any other different type such as film, due to their physical characteristics. As far as I can tell they are X7R or similar. The amplifier was designed approx. 10 years ago and the capacitors have not been changed since it was manufactured.

My immediate thoughts are I believe in line with conventional wisdom, that this type of capacitor should not be used in these locations. Does anyone have any different thoughts on this?

Many thanks, Jim 🙂

Attached are high quality photos and schematics of the circuit in question.

The outputs from the PGA2311 DCAVC are AC coupled to the inputs of the next stage via 2 x 1uF SMT ceramic caps. The legend on the schematic is incorrect, they are non-polarised caps.

One has been removed and measured. I believe they are not NP0/C0G types, or indeed any other different type such as film, due to their physical characteristics. As far as I can tell they are X7R or similar. The amplifier was designed approx. 10 years ago and the capacitors have not been changed since it was manufactured.

My immediate thoughts are I believe in line with conventional wisdom, that this type of capacitor should not be used in these locations. Does anyone have any different thoughts on this?

Many thanks, Jim 🙂

An externally hosted image should be here but it was not working when we last tested it.

Attachments

Looks like the capacitor is an excellent choice and the ESR is very good. One cannot expect to fit wire ended components on an SMD board and after all, the conductivity of SMD components usually exceed wire ended, as long as Lead Free solder is used to solder them or replace them, (it stops leaching of the tin coated conductors at each end of the component).

Hi Jon,

Thanks for the reply. I was not intending to replace with a through-hole component, rather upgrade to a SMT film type.

I can find very many references from reputable and classic sources, articles and books arguing against using ceramic caps in a signal path as shown, I realise they have improved over the years but I don't think this is a type which has been improved - the equipment is fairly old and it looks like a bog standard ceramic as would normally be used for supply bypassing, etc. and I have not seen such caps used in the signal path before, I don't think?

Thanks

Thanks for the reply. I was not intending to replace with a through-hole component, rather upgrade to a SMT film type.

I can find very many references from reputable and classic sources, articles and books arguing against using ceramic caps in a signal path as shown, I realise they have improved over the years but I don't think this is a type which has been improved - the equipment is fairly old and it looks like a bog standard ceramic as would normally be used for supply bypassing, etc. and I have not seen such caps used in the signal path before, I don't think?

Thanks

You'd be surprised at how often caps like this appear in AV equipment.

Panasonic ECPU1C105MA5 is a good replacement, but beware the low voltage ratings of film capacitors in relatively small sizes. This limits the maximum input voltage (I think these are limited to 10VAC, check datasheet). These ones are 1210, which should just about fit into the existing 1210 pad. The presence of bias complicates matters as it reduces the overall voltage handling ability.

If you are aware of the parameters determining the possibility of using them, you can substitute the caps for film types. In this specific case you may have some issues because of the circuit itself.

Panasonic ECPU1C105MA5 is a good replacement, but beware the low voltage ratings of film capacitors in relatively small sizes. This limits the maximum input voltage (I think these are limited to 10VAC, check datasheet). These ones are 1210, which should just about fit into the existing 1210 pad. The presence of bias complicates matters as it reduces the overall voltage handling ability.

If you are aware of the parameters determining the possibility of using them, you can substitute the caps for film types. In this specific case you may have some issues because of the circuit itself.

These are nice caps and mostly 50V working.

Polyphenylene Sulphide Film Capacitors | RS Components

You may have to dig about a bit as the values are a bit limited.

Polyphenylene Sulphide Film Capacitors | RS Components

You may have to dig about a bit as the values are a bit limited.

1uF feeding a load of 47k will have an LF cutoff around 3.3Hz. This may be low enough that there is little signal across the cap, so little scope for generating distortion due to dielectric nonlinearity.

Hi Jim,

Yes, use a film type surface mount. You're going to be further ahead if you pre-tin the capacitor and one pad. Once the new capacitor is positioned properly, solder the other side.

I use eutectic 63/37 solder - leaded. You need the lower temperature and superior wetting too. A touch of liquid flux can do wonders. In this way you can avoid damaged new parts.

I have a pair of Cyrus Mono-X amplifiers I plan to go through. I do expect a big improvement in performance after the changes. I have already purchased the replacement parts (long time ago). I will be following my own advice to you.

Think about replacing those TL072 chips with something like the 2134 or similar. Keep the J-Fet input type op amps in your search for better devices. You can do a lot better than the TL07x series chips.

-Chris

Yes, use a film type surface mount. You're going to be further ahead if you pre-tin the capacitor and one pad. Once the new capacitor is positioned properly, solder the other side.

I use eutectic 63/37 solder - leaded. You need the lower temperature and superior wetting too. A touch of liquid flux can do wonders. In this way you can avoid damaged new parts.

I have a pair of Cyrus Mono-X amplifiers I plan to go through. I do expect a big improvement in performance after the changes. I have already purchased the replacement parts (long time ago). I will be following my own advice to you.

Think about replacing those TL072 chips with something like the 2134 or similar. Keep the J-Fet input type op amps in your search for better devices. You can do a lot better than the TL07x series chips.

-Chris

Thanks for the replies and suggestions 🙂

Yes this thread was mainly posted because in 20 years of working with audio equipment I don't think I have once seen ceramics used for AC coupling between high quality audio stages, and in fact in all that time so much advice has soaked in to the contrary so this came as a bit of a surprise. But I understand there may be minimal distortion for the above reason... it just seemed an unusual choice by the designer.

It is a leaded board and I'm experienced with working with SMT, but thanks for that additional advice all the same. I think I will replace with film as I originally thought, I'll do some careful selection considering the circuit topology and physical constraints.

The amp has already had a lot of work done to it over the past week - it is nearing completion and there is an upper limit to the amount of additional time I can spend doing additional upgrades such as OPAMPS, etc. because it belongs to a customer. The majority of OPAMPS elsewhere are OPA2134.

The majority of the repairs were in the digital stages, I've also renewed electrolytics throughout due to age. Some of the electrolytics for supply filtering were rated at 16V on a 15V supply, so the voltage rating of those has been increased during the repair.

Yes this thread was mainly posted because in 20 years of working with audio equipment I don't think I have once seen ceramics used for AC coupling between high quality audio stages, and in fact in all that time so much advice has soaked in to the contrary so this came as a bit of a surprise. But I understand there may be minimal distortion for the above reason... it just seemed an unusual choice by the designer.

It is a leaded board and I'm experienced with working with SMT, but thanks for that additional advice all the same. I think I will replace with film as I originally thought, I'll do some careful selection considering the circuit topology and physical constraints.

The amp has already had a lot of work done to it over the past week - it is nearing completion and there is an upper limit to the amount of additional time I can spend doing additional upgrades such as OPAMPS, etc. because it belongs to a customer. The majority of OPAMPS elsewhere are OPA2134.

The majority of the repairs were in the digital stages, I've also renewed electrolytics throughout due to age. Some of the electrolytics for supply filtering were rated at 16V on a 15V supply, so the voltage rating of those has been increased during the repair.

I found huge improvement in replacing tantalum 5 uf input caps on my amp with 50 V cop ceramic input caps, aerovox gold to be precise. The original 1970 caps passed less bass, the tantalum replacements had frying pan popping hissing noise. I suspect my local parts store was selling rejects, as was common before e-bay consumed the stock of rejects.

Look at the capacitance versus voltage curve of ceramic, and imagine a 1 v signal impressed on a 50 v cap. The curve is a lot straighter if you use only one fiftieth of the curve.

In your circuit with no diode clamps to the power supply, I'd be more worried about static blowing the TL072 through a low voltage rated film cap. Small size is a limiter.

My amp had an input impedance of about 500kohms to be compatible with 12AX7 plate drive preamps. You might straighten out the curve by curring current flow. Change the input and feedback resistors to achieve an input impedance of 200 kohms or so. If you have to change to metal film resistors to minimize hiss, so be it. Above 100k the difference hiss between metal film and carbon comp resistors is very audible. I've never bought any carbon film resistors to see how they fare in the hiss dimension. A diy poster said metal film was the standard in hiss reduction. I find no reason to buy anything else.

Look at the capacitance versus voltage curve of ceramic, and imagine a 1 v signal impressed on a 50 v cap. The curve is a lot straighter if you use only one fiftieth of the curve.

In your circuit with no diode clamps to the power supply, I'd be more worried about static blowing the TL072 through a low voltage rated film cap. Small size is a limiter.

My amp had an input impedance of about 500kohms to be compatible with 12AX7 plate drive preamps. You might straighten out the curve by curring current flow. Change the input and feedback resistors to achieve an input impedance of 200 kohms or so. If you have to change to metal film resistors to minimize hiss, so be it. Above 100k the difference hiss between metal film and carbon comp resistors is very audible. I've never bought any carbon film resistors to see how they fare in the hiss dimension. A diy poster said metal film was the standard in hiss reduction. I find no reason to buy anything else.

Last edited:

Hi indianajo,

Hi Jim,

If you don't mind me asking, what brand is that in? You can PM me if it is a sensitive issue.

-Chris

Not an issue with this op amp.I'd be more worried about static blowing the TL072 through a low voltage rated film cap.

Hi Jim,

For a good reason. I do believe that a change would be audible, but the customer is always the boss ... well, usually. SMT stuff is a quick swap though. I've been in that biz for >35 years now. I'll agree that ceramic capacitors are unusual to find as coupling capacitors. I have seen this in low end equipment, large 50V disc capacitors. I never stopped to worry about the exact flavor of ceramic as it wasn't NP0 / C0G, that much was certain.The majority of OPAMPS elsewhere are OPA2134.

If you don't mind me asking, what brand is that in? You can PM me if it is a sensitive issue.

-Chris

Hi Chris,

Thanks again for that, and yes I'm not sure why (Primare) used TL072 in these locations and 2134s everywhere else. It's a SPA21 and does have some other oddities which would be a discussion that could last a day, in the digital departments, for instance that ADC is the bottleneck, but it is bypassable. Major modifications were considered in the digital receiver circuits also, I would have really liked to have the same digital capabilities throughout, currently it's a mixed bag (ADC is 48kHz, DAR is <=96kHz, DACs and DSP are 192 capable, etc.) The routing is also fairly strange, certainly if it was my own equipment then (if I had the time) I would be spending it doing further research and design work, because some of it doesn't make sense and is almost asking to be edited a bit 🙂

It's unusual for me to spend this amount of time repairing one item of equipment, I mainly repair pro audio kit not HIFI, and I turn around a lot of repairs. This has been an interesting project however and my customer wants it refurbished up to what is within sensible limits so if you think the change to a 2134 in that location would be very beneficial then I'll do that as well, as you say it's a quick swap. I hadn't really considered it, got distracted by the caps!

Thanks again for that, and yes I'm not sure why (Primare) used TL072 in these locations and 2134s everywhere else. It's a SPA21 and does have some other oddities which would be a discussion that could last a day, in the digital departments, for instance that ADC is the bottleneck, but it is bypassable. Major modifications were considered in the digital receiver circuits also, I would have really liked to have the same digital capabilities throughout, currently it's a mixed bag (ADC is 48kHz, DAR is <=96kHz, DACs and DSP are 192 capable, etc.) The routing is also fairly strange, certainly if it was my own equipment then (if I had the time) I would be spending it doing further research and design work, because some of it doesn't make sense and is almost asking to be edited a bit 🙂

It's unusual for me to spend this amount of time repairing one item of equipment, I mainly repair pro audio kit not HIFI, and I turn around a lot of repairs. This has been an interesting project however and my customer wants it refurbished up to what is within sensible limits so if you think the change to a 2134 in that location would be very beneficial then I'll do that as well, as you say it's a quick swap. I hadn't really considered it, got distracted by the caps!

Hi Jim,

You know your customer, I don't. Most of my customers would agree, but you are spending that man's money. It comes down to his trust level and his ear I guess. It would make for an interesting experiment. It would seem that this one TL072 would be a bottleneck for the audio path. If this is the case, it might make a bigger difference than you might expect. Yeah, I'd change it.

Repairing pro (M.I. over here) is a lot easier than dealing with consumer stuff most times. That part of the business is much less stressful than the consumer market is. Even at the high end of audio, there is a lot of unprofessional behavior, just 'cause. Although I do enjoy working on the classic older gear that performs well.

You're always welcome around here Jim. Have at it!

-Chris

You know your customer, I don't. Most of my customers would agree, but you are spending that man's money. It comes down to his trust level and his ear I guess. It would make for an interesting experiment. It would seem that this one TL072 would be a bottleneck for the audio path. If this is the case, it might make a bigger difference than you might expect. Yeah, I'd change it.

Repairing pro (M.I. over here) is a lot easier than dealing with consumer stuff most times. That part of the business is much less stressful than the consumer market is. Even at the high end of audio, there is a lot of unprofessional behavior, just 'cause. Although I do enjoy working on the classic older gear that performs well.

You're always welcome around here Jim. Have at it!

-Chris

Cheers for the warm welcome Chris.

Yes it's rare I post on here although I've been a member for years, it's the 'shock' factor of finding those coupling caps that made me post, questioning my own sanity for a minute or two, but I'm glad that I haven't gone crazy yet!

Probably about 90% pro audio kit... full time, lots of power amps, mixers, DJ equipment, etc. I do have a design engineer somewhere inside of me screaming to get out most of the time, but there is a such a high demand for repair work where I live that 'projects' are quite rare, unfortunately, but I do make sure all the repair work I do is to the highest standard possible within the client's budget, because reliability of pro kit is top priority. As you say, the HIFI world is slightly stranger, but I am enjoying this one. Any low end consumer equipment wouldn't get such an amount of attention, if any at all.

Returning briefly to the subject - I'll definitely replace that OPAMP. If you saw the rest of the schematics you would probably see what I mean about the digital bottlenecks and oddities there as well, which I consider more important but a line has to be drawn somewhere, especially considering the amount of work that has already been done.

Thanks again for your help 🙂

Yes it's rare I post on here although I've been a member for years, it's the 'shock' factor of finding those coupling caps that made me post, questioning my own sanity for a minute or two, but I'm glad that I haven't gone crazy yet!

Probably about 90% pro audio kit... full time, lots of power amps, mixers, DJ equipment, etc. I do have a design engineer somewhere inside of me screaming to get out most of the time, but there is a such a high demand for repair work where I live that 'projects' are quite rare, unfortunately, but I do make sure all the repair work I do is to the highest standard possible within the client's budget, because reliability of pro kit is top priority. As you say, the HIFI world is slightly stranger, but I am enjoying this one. Any low end consumer equipment wouldn't get such an amount of attention, if any at all.

Returning briefly to the subject - I'll definitely replace that OPAMP. If you saw the rest of the schematics you would probably see what I mean about the digital bottlenecks and oddities there as well, which I consider more important but a line has to be drawn somewhere, especially considering the amount of work that has already been done.

Thanks again for your help 🙂

Hi Jim,

Your take on how repair is done is very similar to my own. I understand you completely. I am exercising my inner designer by redesigning botched "high end" designs. I've been pushed by a few customers to design and build a few things. Time will tell whether that goes well or not.

Let your inner designer out to play. All you need is a case and power supply from something that wasn't worth repair. Now you have a test environment. Everyone needs a hobby - right?

Best, Chris

Your take on how repair is done is very similar to my own. I understand you completely. I am exercising my inner designer by redesigning botched "high end" designs. I've been pushed by a few customers to design and build a few things. Time will tell whether that goes well or not.

Let your inner designer out to play. All you need is a case and power supply from something that wasn't worth repair. Now you have a test environment. Everyone needs a hobby - right?

Best, Chris

That cap is likely of x7r or similar type ceramic which means its capacitance varies with the voltage across, which is what gives ceramic bad reputation for audio application that it rarely deserves. Properly designed circuit ensures minimal voltage variation a x7r ceramic cap is exposed to within the frequency range of interest during operation, usually at lower end of audio band, and minimizes the ill effect the material's characteristic may cause. In this AV amp, if concerned, you can stack mount a Non-polar electrolytic, 4.7 or 10uF, on top of the original 1uF, to further cut down the voltage at low frequencies. The size of the SMD caps appears to be 0805 in the pictures, so this is quite doable.

Hi Chris,

Thanks again for that, and yes I'm not sure why (Primare) used TL072 in these locations and 2134s everywhere else. It's a SPA21 and does have some other oddities which would be a discussion that could last a day, in the digital departments, for instance that ADC is the bottleneck, but it is bypassable. Major modifications were considered in the digital receiver circuits also, I would have really liked to have the same digital capabilities throughout, currently it's a mixed bag (ADC is 48kHz, DAR is <=96kHz, DACs and DSP are 192 capable, etc.) The routing is also fairly strange, certainly if it was my own equipment then (if I had the time) I would be spending it doing further research and design work, because some of it doesn't make sense and is almost asking to be edited a bit 🙂

It's unusual for me to spend this amount of time repairing one item of equipment, I mainly repair pro audio kit not HIFI, and I turn around a lot of repairs. This has been an interesting project however and my customer wants it refurbished up to what is within sensible limits so if you think the change to a 2134 in that location would be very beneficial then I'll do that as well, as you say it's a quick swap. I hadn't really considered it, got distracted by the caps!

So I'm curious as to what has led to this determination that something is wrong with this pre-amp. You've read some references, looked at the parts used, and called out a fairly experienced manufacturer for using a "bad" or substandard part. Have you measured this system? Are these caps for certain causing some sort of measurable or audible problem? I'd love to see THD vs. frequency plots at various operating levels passing through this circuit. This type of measurement is something most hobbyists are unable to measure properly, but most established designers have the equipment to do so.

I looked into distortion from ceramics used in AC coupling capacitors last year and found that it took surprisingly low corner frequencies to eliminate additional distortion. A rule of thumb that I developed from those tests were to put the corner frequency 2 decades below the desired passband to prevent distortion from the coupling capacitor. My test results are shown in this video on TI's website around the 5:35 mark: https://training.ti.com/ti-precision-labs-op-amps-low-distortion-design-4?cu=14685

That video, as well as the other 3 in the low distortion series, might provide some additional useful information for those on this forum.

Part 1: https://training.ti.com/ti-precision-labs-op-amps-low-distortion-design-1?cu=14685

Part 2: https://training.ti.com/ti-precision-labs-op-amps-low-distortion-design-2?cu=14685

Part 3: https://training.ti.com/ti-precision-labs-op-amps-low-distortion-design-3?cu=14685

That video, as well as the other 3 in the low distortion series, might provide some additional useful information for those on this forum.

Part 1: https://training.ti.com/ti-precision-labs-op-amps-low-distortion-design-1?cu=14685

Part 2: https://training.ti.com/ti-precision-labs-op-amps-low-distortion-design-2?cu=14685

Part 3: https://training.ti.com/ti-precision-labs-op-amps-low-distortion-design-3?cu=14685

1decade below the passband is used by D.Self for electrolytics. The same can be applied to the higher distortion plastic film types like MKT/MKS.

2decades for a medium K ceramic seems to be about right.

10uF into 82k gives 0.2Hz F-3dB, or 4u7F into 160k.

and is just about workable.

2decades for a medium K ceramic seems to be about right.

10uF into 82k gives 0.2Hz F-3dB, or 4u7F into 160k.

and is just about workable.

John, thanks for the additional advice, I'll look into those test results with interest.

Ungie, my concern was initiated by never seeing ceramic caps used as shown in any equipment I have worked on in many years, and combined with conventional wisdom I felt that needed investigation.

This item needed a lot of repair work in many different areas and I have been making measurements continuously throughout the project, via Audio Precision test gear, however as I'm sure you can appreciate I can't realistically write up the job online or start posting pages of test results, because that would essentially be a project in itself considering the amount of repair work that has been involved. I rarely write up my work in detail in public for various reasons as I am sure you can understand, in fact it is several years since I have even posted on a forum but was curious to hear other people's opinions on this issue this time.

Cheers 🙂

Ungie, my concern was initiated by never seeing ceramic caps used as shown in any equipment I have worked on in many years, and combined with conventional wisdom I felt that needed investigation.

This item needed a lot of repair work in many different areas and I have been making measurements continuously throughout the project, via Audio Precision test gear, however as I'm sure you can appreciate I can't realistically write up the job online or start posting pages of test results, because that would essentially be a project in itself considering the amount of repair work that has been involved. I rarely write up my work in detail in public for various reasons as I am sure you can understand, in fact it is several years since I have even posted on a forum but was curious to hear other people's opinions on this issue this time.

Cheers 🙂

Hi Andrew,

Isn't is best to avoid this problem to begin with? Seems to me that replacing that capacitor is the most responsible thing to do.

Hi nattawa,

Hi ungie,

I'm going to assume that Jim does the same things I would do. Listen to it for an "as found" reference, then also take common measurements. This is then the recorded starting performance. Then you apply years of experience to the problems you find, then record your after listening impressions and measurements. I just did this with some amplifiers that needed to be redesigned in order to fix the problems. I fixed what needed to be fixed from my knowledge of amplifier design, and ended up with an amplifier that didn't blow up when turned on. The distortion dropped by a factor of 20 some-odd and the customer is elated they sound so good. A predictable end result if you looked at the "as found" performance and saw a failed amplifier that did blow up just from turning it on. These were very expensive amplifiers. The stereo version was written off as unrepairable. The design was also failure prone and it didn't have any speaker protection sat all. There was 26 volts across the speaker terminals and the fuses didn't blow. Can you say fire in speaker? That amplifier was destroyed before recycling it in case someone decided to try and fix it.

I can tell Jim is a professional in this field and I am not going to second guess the man.

Sometimes, even a good manufacturer designs a problem unit. Take the Revox (great brand!) B-251. That one had some design issues, and some build problems. The fix consisted of exchanging some parts for higher rated ones, but that design would always have a heat issue. At least they include good speaker protection. That brand made some of the best equipment going at some points in their history, and I would love to own some of it (not the B-251). The point is, a well known company that has a sterling reputation can make mistakes. It is up to the technician to either advise the customer not to repair the bad ones, or to redesign portions if that is viable. Obviously, the technician must have long experience, great workmanship and advanced knowledge of the equipment he works on. BTW, the word "he" applies to both men and women equally.

-Chris

Isn't is best to avoid this problem to begin with? Seems to me that replacing that capacitor is the most responsible thing to do.

Hi nattawa,

Then why wouldn't you just replace it with the bypass capacitor? Not unless you are determined to keep the problem component in the circuit.if concerned, you can stack mount a Non-polar electrolytic, 4.7 or 10uF, on top of the original 1uF, to further cut down the voltage at low frequencies.

Hi ungie,

Experience.So I'm curious as to what has led to this determination that something is wrong with this pre-amp.

I'm going to assume that Jim does the same things I would do. Listen to it for an "as found" reference, then also take common measurements. This is then the recorded starting performance. Then you apply years of experience to the problems you find, then record your after listening impressions and measurements. I just did this with some amplifiers that needed to be redesigned in order to fix the problems. I fixed what needed to be fixed from my knowledge of amplifier design, and ended up with an amplifier that didn't blow up when turned on. The distortion dropped by a factor of 20 some-odd and the customer is elated they sound so good. A predictable end result if you looked at the "as found" performance and saw a failed amplifier that did blow up just from turning it on. These were very expensive amplifiers. The stereo version was written off as unrepairable. The design was also failure prone and it didn't have any speaker protection sat all. There was 26 volts across the speaker terminals and the fuses didn't blow. Can you say fire in speaker? That amplifier was destroyed before recycling it in case someone decided to try and fix it.

I can tell Jim is a professional in this field and I am not going to second guess the man.

Sometimes, even a good manufacturer designs a problem unit. Take the Revox (great brand!) B-251. That one had some design issues, and some build problems. The fix consisted of exchanging some parts for higher rated ones, but that design would always have a heat issue. At least they include good speaker protection. That brand made some of the best equipment going at some points in their history, and I would love to own some of it (not the B-251). The point is, a well known company that has a sterling reputation can make mistakes. It is up to the technician to either advise the customer not to repair the bad ones, or to redesign portions if that is viable. Obviously, the technician must have long experience, great workmanship and advanced knowledge of the equipment he works on. BTW, the word "he" applies to both men and women equally.

-Chris

- Status

- Not open for further replies.

- Home

- Source & Line

- Analog Line Level

- SMT ceramic cap found in critical audio path in high end AV amplifier, please advise?