Can anybody recommend surface mount resisters that are non-magnetic and very high quality, suitable for feedback circuits and high gain areas like phono stage ? I've got loads of choice from the basic to the ludicrous in through hole, but I don't see the same choice in SMD.

First ones I'm looking for are to bias op amp into class A, currently have through hole resisters soldered into an 8 pin socket, which despite being small, are still too large and I thought SMD would be a good replacement.

I've read a lot of people denigrating SMD for audio, but there must be some devices which are suitable, low inductance, low noise, non-magnetic etc. All DACs and streamers use SMD and some of the DACs I've heard sound very fine indeed, I just need to understand what's available.

Thanks

First ones I'm looking for are to bias op amp into class A, currently have through hole resisters soldered into an 8 pin socket, which despite being small, are still too large and I thought SMD would be a good replacement.

I've read a lot of people denigrating SMD for audio, but there must be some devices which are suitable, low inductance, low noise, non-magnetic etc. All DACs and streamers use SMD and some of the DACs I've heard sound very fine indeed, I just need to understand what's available.

Thanks

They are all low inductance and the thin film and the MELF types have low 1/f noise. I don't know about your other requirements.

Mostly spoken out of fear of smd components/their size. Disregard what you read about it most of the time 🙂I've read a lot of people denigrating SMD for audio,

For signal path, get susumu rs if available in value, if not, susumu rg series. Good cheap, yageo melf also.

Thanks, I got a handful of values of Holsworthy TE Connectivity resisters, they are 0.1% 10ppm/*C, don't need quite that tolerance but won't hurt and seemed a good place to start, I'm not Atari buying in millions, just 10 of each value. I'll look out for Susumu next time.

One thing you should know about thin film resistors is that they can easily be damaged when you solder them with a much too hot soldering iron.

Yes, a temperature-controlled soldering iron is pretty much a requirement these days. Over hot irons tend to damage the PCB laminate as well.

I need a new solder station, maybe now is a good time to buy it. I’ve managed to hand solder SOIC opamps to a carrier, just difficult seeing such small pads.

Btw, thin film, thick film resistors, you won't hear the difference anyway. If someone says otherwise then he's a member of the audiophoolery club. 😉

/me waiting for sticks and stones thrown at me 😁

/me waiting for sticks and stones thrown at me 😁

You have more chance to damage your pcb when your iron is not hot enough and you need to heat too long.Yes, a temperature-controlled soldering iron is pretty much a requirement these days. Over hot irons tend to damage the PCB laminate as well.

This "only just above melting point of the solder" if fine for oven or reflow soldering because the whole pcb and components are heated (with a large heat source) to that temperature.

Running at 380'C here (715F). At 325'C I sometimes have to heat for a long time as the PCB/part just keeps absorbing all the heat before the solder can melt.

Yes, I did notice my autocorrect constantly gets it wrong. I'll take it outside and beat it with a long stick when I get time.Resist o rs ;-D

//

I have noticed a difference in a pre-amp between carbon and metal film, through hole. No idea if that difference will exist in SMD, comparing 50+ year old tech with probably 10 year old SMD technology, no idea, will have to experiment.Btw, thin film, thick film resistors, you won't hear the difference anyway. If someone says otherwise then he's a member of the audiophoolery club. 😉

/me waiting for sticks and stones thrown at me 😁

Use SMD thinfilm resistors, not thickfilm.... As small as you feel like soldering, size 1206 is easy, 0402 is hard..... I use Susumu resistors a lot, only good experience. Get a good temperature controlled soldering iron with a small tip. Get a magnifying lamp with LED lightning. A heat gun is good for desoldering. Use thin solder, like 0.3mm dia, for diy use lead/tin solder.

10 year old SMD technology

Just a little longer than 10 years, SMD resistors have been around since the early 1980's.

Btw, thin film, thick film resistors, you won't hear the difference anyway. If someone says otherwise then he's a member of the audiophoolery club.

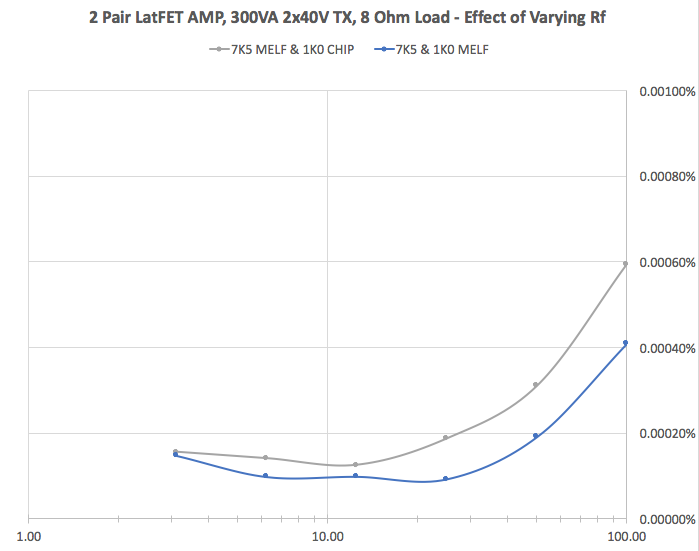

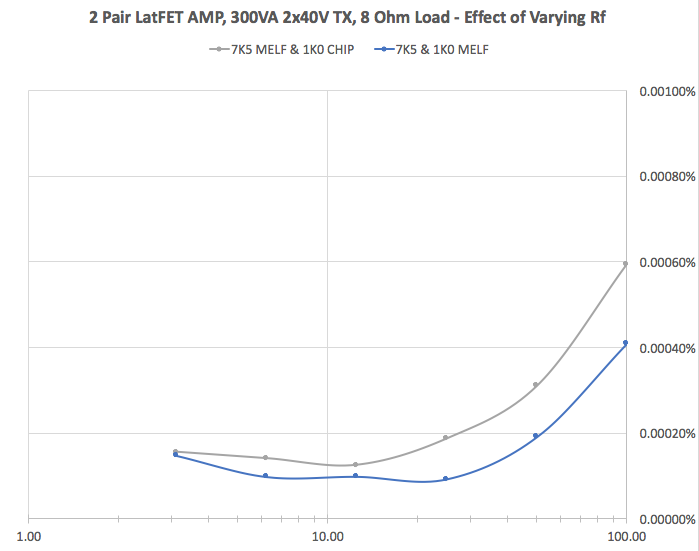

Very true, however from an engineering perspective don't use thick film resistors in the feedback path of a power amplifier, there can be measurable differences in distortion.

So, there's another resistor in this feedback network. That's also a thick-film chip resistor. Swapping it for a MELF has a much less dramatic effect on distortion, but definitely measurable, which makes sense as the voltages on this resistor are much smaller.

There's two more resistors on the other side of the input which are used to set bandwidth. The 750R in series is already a MELF, for no good reason other than that's...

There's two more resistors on the other side of the input which are used to set bandwidth. The 750R in series is already a MELF, for no good reason other than that's...

Last edited:

They've arrived. Photo on the label from Farnell. Nano SIM on the right for size. The SMD resistors (o 🙂 ) are the four little black rectangles below the four dots on the white strip. They must have to employ young people to make these, nobody over the age of 30 will ever see these with the naked eye !

Attachments

Those are 0603 size, that is LARGE (in current production environments) 😱 0603 is about the smallest I use in manual soldering like pull-ups and 100n decoupling. But industry is already past that for years. When I was still designing electronics for a living 0603 was the goto size (except large capacitors), passives in digital were typically 0402. And for phones 01005 was becoming usual.

- Home

- Design & Build

- Parts

- SMD resisters