an I ask why you see the epique drivers as having poor compliance?

I have put that wrong. The non linearity isnt an issue on the Epique, its quite good (however i was comparing the E180 not the 5,5" variant).

For reference: The E180 does 10mm with 10% distortion. Link to test

Its easy to calculate: just take the inverse of Kms, (1/kms) and take the displacement where the inverse of Kms drops to 75% for 10% distortion and 50% for 20% distortion.

This is here: 75% = (1/1,6) / ((1/1,2)/100), so at 1,6N/mm is 10mm displacement.

Granted they show non symmetry so I just take the highest value. In reality this unsymmetry will result in different amounts of distortion for the + peak of the sine vs the - peak of the sine. Resulting in more even order vs odd order distortion.

The purifi on the other hand shows almost no unsymmetrty so should produce more odd order distortion compared to even.

Whats better? No idea!

I just found that the high stiffness and high loss combined makes it loose 2db.

Green is the Purifi PR vs red the Dayton E180

Its not super bad and the suspension is good for the amount of travel needed.

@white as said, the efficiency in the bass range is not as high for your speaker. There is Hoffmanns iron law and a few exceptions with some trickery, e.g. as Brane or Devialet were attempting.

One the one hand, i development my own amplifier with several multiphase DCDCs and dsp/envelope codes to achieve high efficiency as well as putting a big battery in. On the other hand - for sure id like to have something more efficient - but there is nothing suitable.

@Farbe not only prototypes - finished speakers. Like 10 or 15 of them, i've been doing that hobby for like 15 years now 😅

One the one hand, i development my own amplifier with several multiphase DCDCs and dsp/envelope codes to achieve high efficiency as well as putting a big battery in. On the other hand - for sure id like to have something more efficient - but there is nothing suitable.

@Farbe not only prototypes - finished speakers. Like 10 or 15 of them, i've been doing that hobby for like 15 years now 😅

This is my PR vs port comparison, see link below.

Thanks very nice!

Looks like the harmonic distortion theory isnt far off based on your measurements.

However i cant really draw a conclusion for the compression, your PRs where very big -> so low amounts of total deflection and therefore ?maybe? lower amounts of influence of the kms stiffness variation.

Its a very nice data point non the less.

BTW looks like we live in the same city! Do you have an idea where I can do ground plane measurements without disturbing someone? I might just drive to SCS on a weekend and measure in their parking space 😀

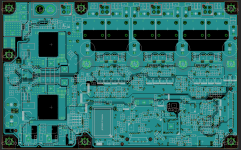

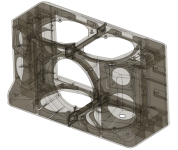

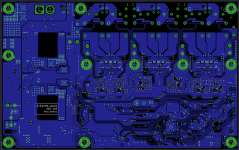

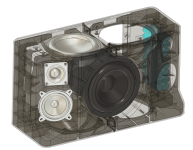

Here a some pictures of the system, the electronics and two videos. (SPL taken with a calibrated mic)

If someone wants more details...just ask

If someone wants more details...just ask

Attachments

-

email1746973005225.jpg395.3 KB · Views: 19

email1746973005225.jpg395.3 KB · Views: 19 -

WhatsApp Video 2024-04-06 um 17.14.48_d05c8218.mp47 MB

-

WhatsApp Video 2024-04-06 um 17.14.48_f6f437f9.mp41.9 MB

-

email1746973002509.jpg195.1 KB · Views: 25

email1746973002509.jpg195.1 KB · Views: 25 -

email1746973008157.jpg410 KB · Views: 24

email1746973008157.jpg410 KB · Views: 24 -

email1746973010692.png231.8 KB · Views: 26

email1746973010692.png231.8 KB · Views: 26 -

email1746973019942.png535.8 KB · Views: 16

email1746973019942.png535.8 KB · Views: 16 -

email1746973013063.png192.1 KB · Views: 17

email1746973013063.png192.1 KB · Views: 17 -

email1746973026944.jpg158 KB · Views: 23

email1746973026944.jpg158 KB · Views: 23 -

email1746973024594.png730.6 KB · Views: 24

email1746973024594.png730.6 KB · Views: 24 -

email1746973022122.png530.7 KB · Views: 20

email1746973022122.png530.7 KB · Views: 20 -

email1746973017687.png202.2 KB · Views: 14

email1746973017687.png202.2 KB · Views: 14 -

email1746973015396.png263.9 KB · Views: 18

email1746973015396.png263.9 KB · Views: 18

Nice work!

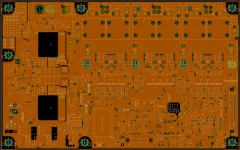

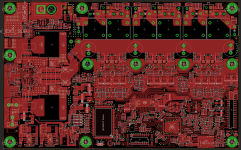

I recently (when autodesk brought eagle) switched to Kicad, I preffer it very much over the new buggy Autodesk Fusion/Eagle integration.

Your design isnt force canceling, so might i ask why you push that so much? Do you have issues with your moving mass? Your posts show 110g tuning mass so 220g wobbeling around might be the issue. How heavy is your enclosure total?

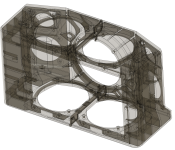

I really like the 3D printed speaker protection grill. I will try something similar: I will try to bend hexagonal aluminum perforated sheet. It should be doable with just a vice and 3d printed forms.

I recently (when autodesk brought eagle) switched to Kicad, I preffer it very much over the new buggy Autodesk Fusion/Eagle integration.

Your design isnt force canceling, so might i ask why you push that so much? Do you have issues with your moving mass? Your posts show 110g tuning mass so 220g wobbeling around might be the issue. How heavy is your enclosure total?

I really like the 3D printed speaker protection grill. I will try something similar: I will try to bend hexagonal aluminum perforated sheet. It should be doable with just a vice and 3d printed forms.

Actually, it is force cancelated. 2 PRs on Top and 2 PRs on the bottom. There is no Problem^^

The enclosure without anything in it is 1.2kg (PETG CF). The "flat" grills are quite easy, but for that "bent in every direction" nightmare i really had to put effort into well printable construction and needed some tries. Also, the filament for this one is PA12CF, works better in that orientation.

Fusion is still my to go tool. in the professional world, i more involved with Creo, but that one is a nightmare regarding easy of use.

The enclosure without anything in it is 1.2kg (PETG CF). The "flat" grills are quite easy, but for that "bent in every direction" nightmare i really had to put effort into well printable construction and needed some tries. Also, the filament for this one is PA12CF, works better in that orientation.

Fusion is still my to go tool. in the professional world, i more involved with Creo, but that one is a nightmare regarding easy of use.

Ah ok I see there are two PRs on top and bottom, so thats not the one you where talking about here:

This is the one i am interested in. Your sims show 110g additional weight so you would have at least 110g moving around without force cancellation.

Thats a little less than my 80g total PR mems so i was trying to draw some conclusions about your experience regarding "speaker rattle".

I also use fusion for MCAD but KiCad for ECAD. I used Eagle for >15 years so i know a eagle color scheme when i see it 😉

this would be my current mobile speaker (Dayton Eqpiue 150HE with 3x SB16PFC PR

This is the one i am interested in. Your sims show 110g additional weight so you would have at least 110g moving around without force cancellation.

Thats a little less than my 80g total PR mems so i was trying to draw some conclusions about your experience regarding "speaker rattle".

I also use fusion for MCAD but KiCad for ECAD. I used Eagle for >15 years so i know a eagle color scheme when i see it 😉

ah yea... the 3 PR one. Remember, as far as i know the additonal weight for the PRs in winlsd is TOTAL. not per PR.

It’s per cone not total, you can variefy that by checking how fs doesn’t change if you add PRs but it should drop if the mass would be split across all cones.

So this one is still in the planning phase? No data on housing vibrations?

Would have been a nice data point to compare.

So this one is still in the planning phase? No data on housing vibrations?

Would have been a nice data point to compare.

i thought that too, used the suggested weights and the tuning was much too low 😀

there is a printed enclosure, but not assembled yet. i do not think there will be a problem, the overall speaker has to much mass, the sub alone is like 4kg ... but, we will see. would have been great to meet up <.<

there is a printed enclosure, but not assembled yet. i do not think there will be a problem, the overall speaker has to much mass, the sub alone is like 4kg ... but, we will see. would have been great to meet up <.<

Loading 3 PRs in a hexagon on alternating walls will make them balanced with regard to the origin.

😊BTW looks like we live in the same city!

I was thinking about the courtyard at my house, but it's probably annoying for neighbours ...I might just drive to SCS on a weekend and measure in their parking space

SCS is great, maybe just a bit noisy from the highway nearby.

I will stick with my design. Its not balanced but its certainly easier to make in CF.

I got confirmation that the purifi PR uses the same suspension as the woofer like i suspected.

They dont want to give me suspension data for the full 15mm xmax though 😉 why oh why 😉.

I want to do ground plane so i need a acoustically hard surface, a dirt field wont do it ;(

Something like a parking lot, asphalt, concrete or pavers would do.

I think this parking lot should work: https://maps.app.goo.gl/b98BjuBcCCbU9HWL9

Its next to train tracks so the neighbours should be acquainted to some noise.

I dont think a few sweeps between trains would annoy them very much, hopefully.

Not sure if somebody would like to meet up and join my measurements, drop me a PM if you want.

I am currently working on the PCB so not sure when I will get to measuring.

I got confirmation that the purifi PR uses the same suspension as the woofer like i suspected.

They dont want to give me suspension data for the full 15mm xmax though 😉 why oh why 😉.

Another guy from here? Wow!fields southeast of Ganserndorf

I want to do ground plane so i need a acoustically hard surface, a dirt field wont do it ;(

Something like a parking lot, asphalt, concrete or pavers would do.

I think this parking lot should work: https://maps.app.goo.gl/b98BjuBcCCbU9HWL9

Its next to train tracks so the neighbours should be acquainted to some noise.

I dont think a few sweeps between trains would annoy them very much, hopefully.

Not sure if somebody would like to meet up and join my measurements, drop me a PM if you want.

I am currently working on the PCB so not sure when I will get to measuring.

3D Printers for the win! Prototyping something like this gets so enjoyable. By the way, there is also some good passive radiators from wavecor, might be worth a look too.

I did the prototype 3D printed. Its just way to leaky and flexible and i already printed it 650g heavy..

I like 3D printing for stuff like that but sometimes its just not the right tool. A quick MDF box would have been way better.

I am just to lazy to whip one up right now 😀

Carbon fiber is so unique and relatively simple to work with that i really want to try it, I just enjoy trying new stuff so cutting MDF feels like a chore while making the CF housing is enjoyable to me even though it takes way more work.

And I even get an idea if the intended housing is stiff enough or doesnt have enough damping.

So yes its silly but I like it 😀

I like 3D printing for stuff like that but sometimes its just not the right tool. A quick MDF box would have been way better.

I am just to lazy to whip one up right now 😀

Carbon fiber is so unique and relatively simple to work with that i really want to try it, I just enjoy trying new stuff so cutting MDF feels like a chore while making the CF housing is enjoyable to me even though it takes way more work.

And I even get an idea if the intended housing is stiff enough or doesnt have enough damping.

So yes its silly but I like it 😀

I dont know what capabilities your printer has, but in the last month i more or less exclusively use bambulab ABS-GF. Stiff, high temp resistance, prints more or less without much warping, more similar to petg then to actual ABS ... and doesnt cost an arm and a leg.

The nnice thing about our hobby: it doesnt need a justification. If its fun, go for it 😀

The nnice thing about our hobby: it doesnt need a justification. If its fun, go for it 😀

- Home

- Loudspeakers

- Multi-Way

- Small+Loud+Light BT Speaker Build