Hi Marc

nichrome wire is made of Nickel and Chromium, and has a relatively high resistivity, and therefore resistance, depending on diameter.

Look here for typical values: wires.co.uk : Bare Nickel Chrome / Nichrome Section

I have had good results with Costantan wire which has a better TC than NiCrome - this wire sounds better that any commercially available resistors I have tried. Ideal for low values. I have been using this wire in my amps as o/p degeneration & o/p resistors / fuses for years.

wires.co.uk : Copper Nickel / Constantan / Eureka Section

But I am informed that manganin is considered better that constantan: even lower TC and also much less nickel in the mix and thus less "magnetic" but I didn't try it yet.

WIRES.CO.UK MANGANIN

Last edited:

Hi Hugh,

I have done a long term chemical analysis ( I would not know how ) but the Constantan wire seems to solder without problems - Havn't used my Manganin yet

I have done a long term chemical analysis ( I would not know how ) but the Constantan wire seems to solder without problems - Havn't used my Manganin yet

They are Copper alloys. But i wonder about thermal dissipation and corrosion ?Can you solder these special wires?

My coils of constantan are more than 5 years old and the appearance has not changed in that time.

My coils of constantan are more than 5 years old and the appearance has not changed in that time.

NAIM uses same solution for years

😉

Attachments

seems like a nice project for someone, there!

My partner uses nichrome wire as elements in her kiln, which has been up to 1100°C and back again virtually every other day for ten years without problem!

My partner uses nichrome wire as elements in her kiln, which has been up to 1100°C and back again virtually every other day for ten years without problem!

Our company has used it as shunt (load-sensing) resistors for 50 years. Nickel/chrome does not corrode and can be soldered. The wire resistor will outlast the solder joint.

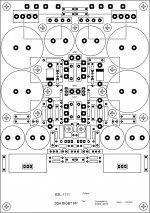

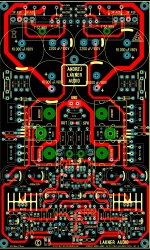

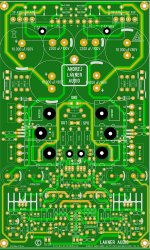

Interesting events development, Alex didn't accepted my board proposal (too densely populated), so it looks we will have the SSA BIGBT HP PCB design competition here hehehe. 😀

Lots of fun ahead yeah.

Lots of fun ahead yeah.

Attachments

Last edited:

LC you are a master in amp ingeniering .....but a master in.......teasing too......

Marc

Marc

Last edited:

120mm fits perfekt in a modu 4U/300 with 165mm internal height, giving a nice chunky look 😀

and those heatsink should make it indestructable in any load 😉

It can be nicely installed in 3HU (132 mm) as side external heatsinks as well. 120mm x 170 mm SSA BIGBT HP PCB plus 400VA/120 mm (diameter) x 80 mm toroidal transformer, fits perfectly on a 132 mm x 300 mm x 40 mm Fischer heatsink as compact all-in-one amplifier module. 😉

Last edited:

... and just for a comparison, the one (too big for me) who's gonna be developed further by Alex. I wonder mhmm 🙄

Try to get you solderiron down between the caps to solder the power transistors/mosfets!😱

I go for Alex... Sorry Lazy cat

OK as you wish, but all the bigs caps are soldered at the end of construction, when all other components are already installed. All under PCB BJT's must be mechanically fixed to flat firm surface and than soldered to PCB, after low profile components (diodes, LEDs resistors, etc.). SSA "construction work" (installation) manual will follow. 😀

It all depends on priorties one demands to follow. Major one ahead of this design here is to maintain high bandwidth results from protoboard measurements. It will be PITA to get there but anyway ... 😉

P.S. This will be double sided PCB and big caps are 50 mm height.

It all depends on priorties one demands to follow. Major one ahead of this design here is to maintain high bandwidth results from protoboard measurements. It will be PITA to get there but anyway ... 😉

P.S. This will be double sided PCB and big caps are 50 mm height.

Last edited:

LC you are a master in amp ingeniering .....but a master in.......teasing too......

Marc

Tnx hehehe I know ... the more fun the better results 😉

...... Andrej can you show as the layout of yours ? I can 😀

Ooooh nice try Alex, outputs in the middle, splendid

But my demand is max. PCB dimensions of 120 mm x 170 mm because of the standard heatsink size 300 mm and beside PCB also to accomodate 400VA transformer on it. 🙄

It can be nicely installed in 3HU (132 mm) as side external heatsinks as well.

ah, ok, I didnt know this

though, seems there are still room fore 'interpretations'

as per the 3U 133mm rack size standard, modushop appear to measure their entire box brutto height, and thus internal height is only 120mm

but doesnt matter when there is a 4U 😉

ARGGGG double side pcb board....a pity to etch at house....so it seems that i need to spend many time on eagle for sigle side way.... with more room needed. LC i suppose that BIGBT HP in lowaer rail voltage count same parts number as your hightest version...only value changing inside????

Marc

Note : NJL4302DG arrived today so yet i have 5 couples NJL4281DG/4302DG for SSA_TT_35V

Marc

Note : NJL4302DG arrived today so yet i have 5 couples NJL4281DG/4302DG for SSA_TT_35V

Last edited:

It is only a suggestion. Move the el-caps a bit away and place polyprop caps close instead.

El-caps does not go higher than a few hundred kilohertz. The film caps stretches to around a few megahertz.

El-caps does not go higher than a few hundred kilohertz. The film caps stretches to around a few megahertz.

- Status

- Not open for further replies.

- Home

- Amplifiers

- Solid State

- Simple Symetrical Amplifier