Hello again!

Being thinking too much, I ask myself how to come by with troubles with EMI etc.

Firstly, I had to tuck my UFSP phono pre as far away as possible to get it out of the range of the other trannies (preamp, poweramp, computer). Would it help and be sensible to put the boards into a shielding case of iron inside the aluminium-chassis?

And secondly, I am currently working on a tight build (the holy grail , mine is at #548), where the PSU will be stacked and placed inside the amp, and try to make up a shielding solution… so I’m thinking about building something like a shielding-case inside the chassis.

Should the rectifier be included in the shield? (Would this help?)

Same with the CRC block…

Being thinking too much, I ask myself how to come by with troubles with EMI etc.

Firstly, I had to tuck my UFSP phono pre as far away as possible to get it out of the range of the other trannies (preamp, poweramp, computer). Would it help and be sensible to put the boards into a shielding case of iron inside the aluminium-chassis?

And secondly, I am currently working on a tight build (the holy grail , mine is at #548), where the PSU will be stacked and placed inside the amp, and try to make up a shielding solution… so I’m thinking about building something like a shielding-case inside the chassis.

Should the rectifier be included in the shield? (Would this help?)

Same with the CRC block…

to put the boards into a shielding case of iron

A shielding case of aluminium, not iron, like Hammond 1590 series boxes.

so I’m thinking about building something like a shielding-case inside the chassis.

Very good for housing the sensitive circuits, indeed.

Should the rectifier be included in the shield?

No. installed outside.

T

Hei, thanks, tubelectron, for the reply.

I‘m wondering a little about your recommendation to put them into an aluminium-box? (The phono-pre already is in one, and picks up transformer-noises as if it was chocolat… (and many are voicing in favor of magnetic material, like iron, mu-metal etc. for shielding purposes…)

Hmm.🤨

Still, bon dimanche!

I‘m wondering a little about your recommendation to put them into an aluminium-box? (The phono-pre already is in one, and picks up transformer-noises as if it was chocolat… (and many are voicing in favor of magnetic material, like iron, mu-metal etc. for shielding purposes…)

Hmm.🤨

Still, bon dimanche!

I know this, @myleftear - Thanks !

Many are voicing that etc, OK... But not so much really experiment ! So here's my take on the subject, based on my personal experimentations...

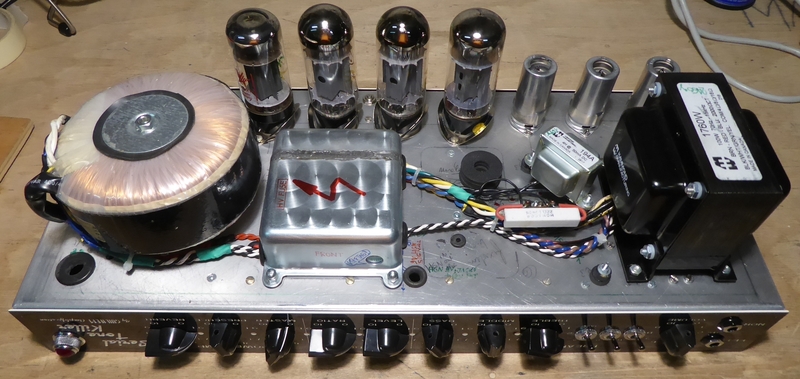

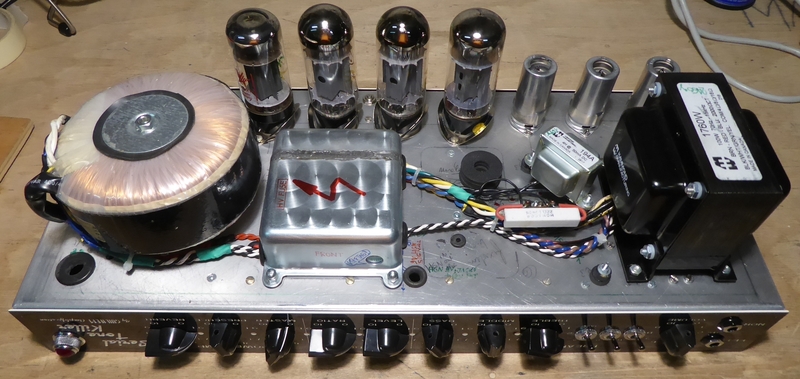

When I wanted to build my Serial Tone Killer guitar amp :

I used for the power supply a toroidal transformer :

And had an amp ridden with hum and buzz at moderate to high gain or volume settings. Even with a humbucker fitted guitar, it remained unbearably unacceptable !

It took me time to discover - at my surprise - that the culprit was not a wiring or layout issue, but that toroidal power transformer, by moving it away as far as possible offered by its wires... Many are voicing that toroidal transformers are quieter, etc... Right ? C'est ça, ouais !

So I thought that the transformer was defective, despite being brand new. I replaced it with another one coming from a Hi-Fi COPLAND 2x40W tube amplifier, that I put under shielding and surelevated slightly from the chassis. The shiedling cover was made from 1mm steel, while the bottom plate was 3mm aluminium :

A slight improvement occured, but by the way still totally unacceptable for me !

Then I shifted for a good old but brand new EI transformer, after making some magnetic and electric radiation tests :

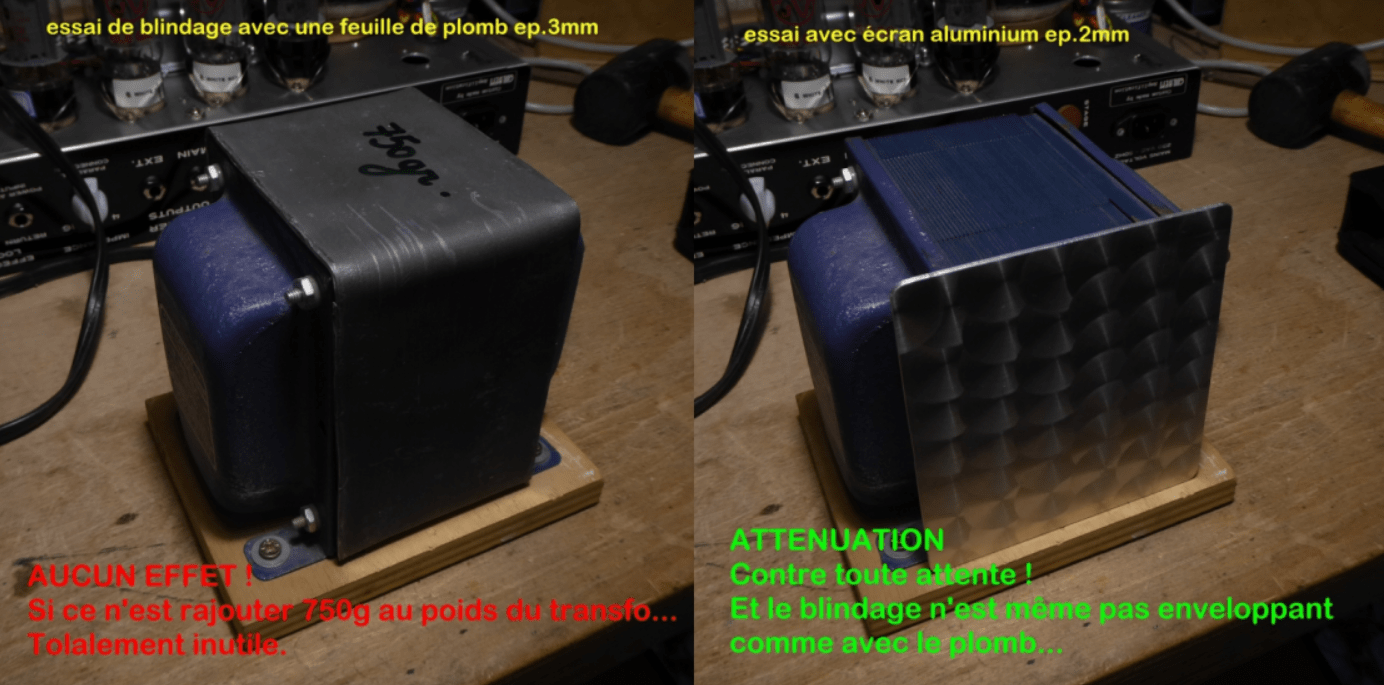

I tested 1mm steel and 3mm lead covers, and 2mm aluminium plate, even µmetal 0.2mm foil, to discover that steel, lead and µmetal were useless, while a simple 2mm aluminium plate could cut with great efficiency the radiations... To my great surprise !

In the meantime, I called my colleagues at ALSTOM Transformers Division, and they usefully instructed me about the toroidal pro and cons, vs. EI transformers, plus the virtues of aluminium sheilding !

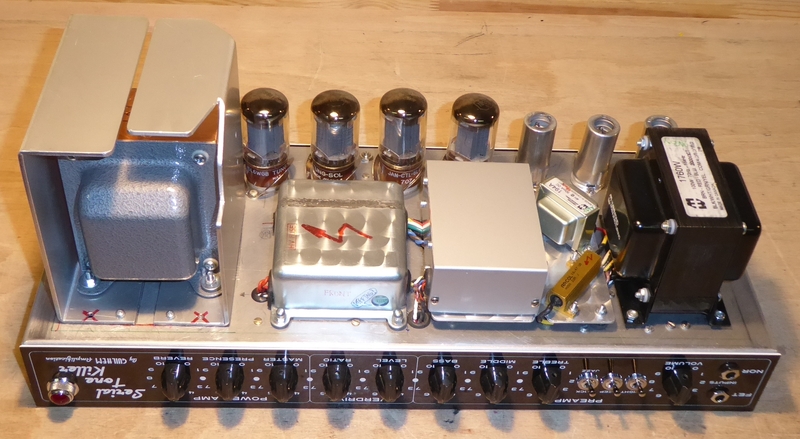

So I went for this solution below :

The EI PSU transformer has been suitably orientated for minimum influence, plus I installed two 3mm thick aluminium "wings" to cut the magnetic radiation from the core. I also installed a copper flux band around the winding to prevent electrical radiation.

Result : complete eradication of the noises, no more influence on the circuits, on the speaker or on any guitar, no matter the amp settings !

So yes, aluminium is efficient against hum and buzz radiations... Despite what many people say !

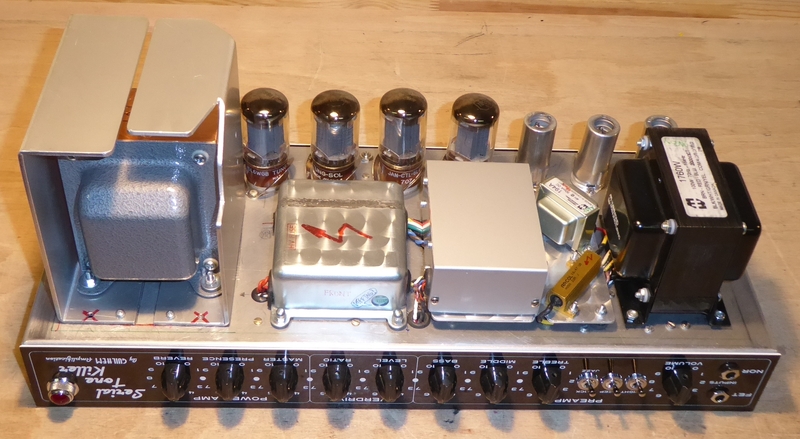

Another successfull example below, this time about a tube line/phono preamplifier - more in your field of application, @myleftear :

I firstly installed the toroidal transformer without special precautions, but nonetheless as far as possible of the circuits. Again : welcome to the unbearable hum and buzz world !

C'est bon, cette fois j'ai compris... Then :

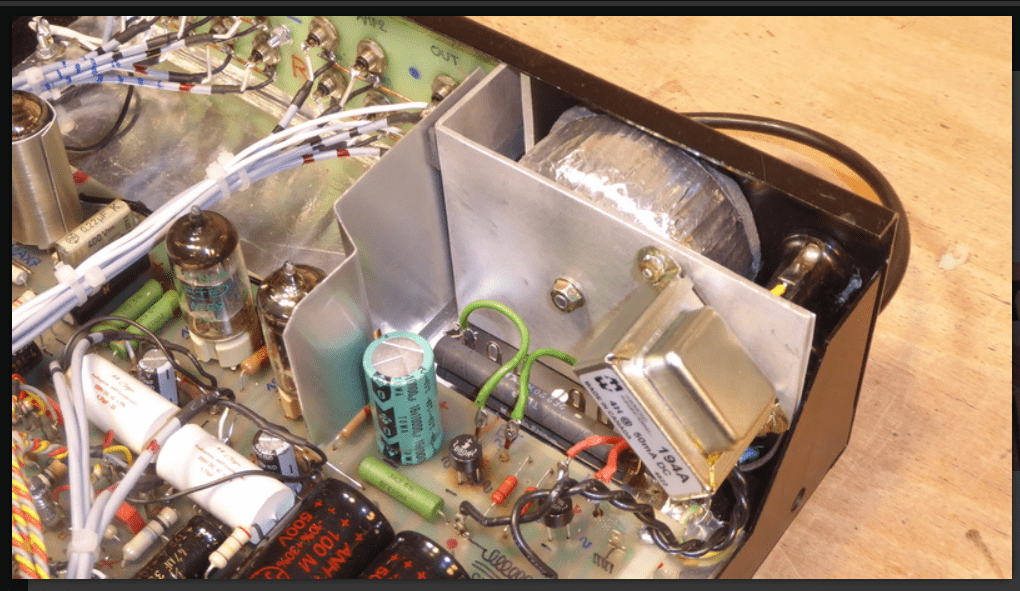

The toroidal transformer is primarily encapsulated with 3 layers of aluminium conductive-adhesive foil, then placed behind a 2mm aluminium screen, plus an additional separation 0.5mm screen between the supply and the output tubes, all grounded. The chassis base, back and frontface bottoms have been covered with the same adhesive aluminium foil, in order to offer a continuous ground plane :

Doing this : I took great care not to short the transformer by the center screw and the aluminium shield, by creating a short-circuit buckle or turn.

Result : dead quiet preamp at any setting, complete eradication of any hum and buzzz... So yes again : aluminium is effective against perturbations.

In my next tube preamp build, I will go for the double boxing solution : the audio circuit will be completely encased in an inside Hammond aluminium box, with just the tubes protruding on their sockets and tubular locking shieldings. And for the PSU transformer, at least there will be screens if not a complete encasing.

T

Many are voicing that etc, OK... But not so much really experiment ! So here's my take on the subject, based on my personal experimentations...

When I wanted to build my Serial Tone Killer guitar amp :

I used for the power supply a toroidal transformer :

And had an amp ridden with hum and buzz at moderate to high gain or volume settings. Even with a humbucker fitted guitar, it remained unbearably unacceptable !

It took me time to discover - at my surprise - that the culprit was not a wiring or layout issue, but that toroidal power transformer, by moving it away as far as possible offered by its wires... Many are voicing that toroidal transformers are quieter, etc... Right ? C'est ça, ouais !

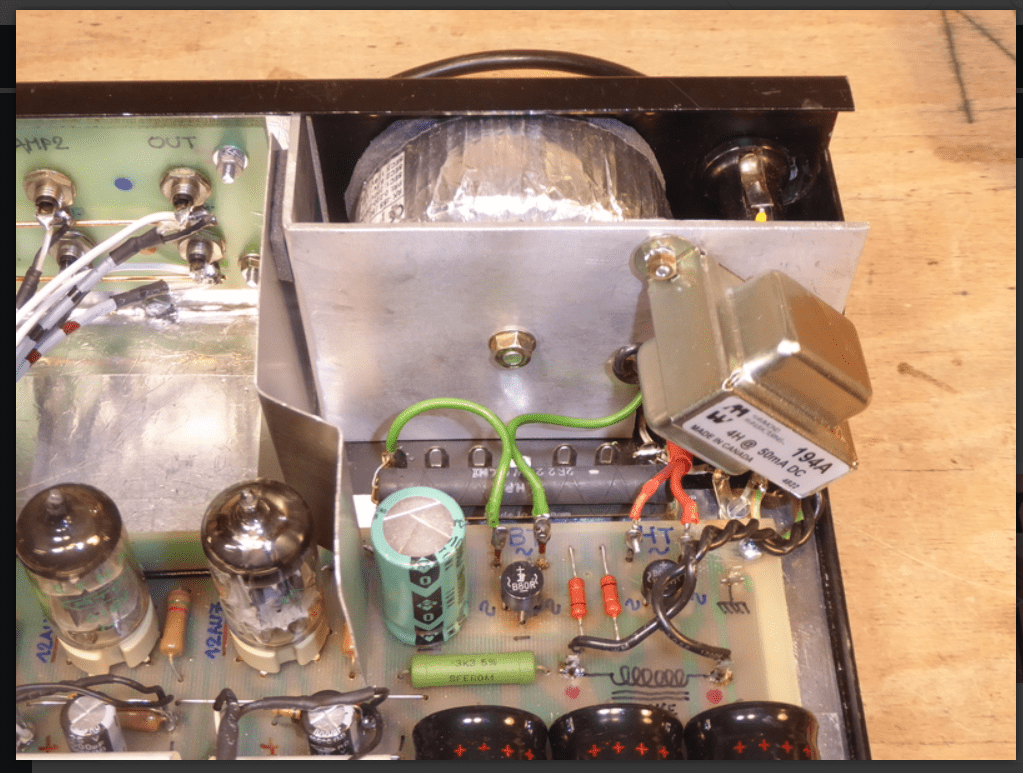

So I thought that the transformer was defective, despite being brand new. I replaced it with another one coming from a Hi-Fi COPLAND 2x40W tube amplifier, that I put under shielding and surelevated slightly from the chassis. The shiedling cover was made from 1mm steel, while the bottom plate was 3mm aluminium :

A slight improvement occured, but by the way still totally unacceptable for me !

Then I shifted for a good old but brand new EI transformer, after making some magnetic and electric radiation tests :

I tested 1mm steel and 3mm lead covers, and 2mm aluminium plate, even µmetal 0.2mm foil, to discover that steel, lead and µmetal were useless, while a simple 2mm aluminium plate could cut with great efficiency the radiations... To my great surprise !

In the meantime, I called my colleagues at ALSTOM Transformers Division, and they usefully instructed me about the toroidal pro and cons, vs. EI transformers, plus the virtues of aluminium sheilding !

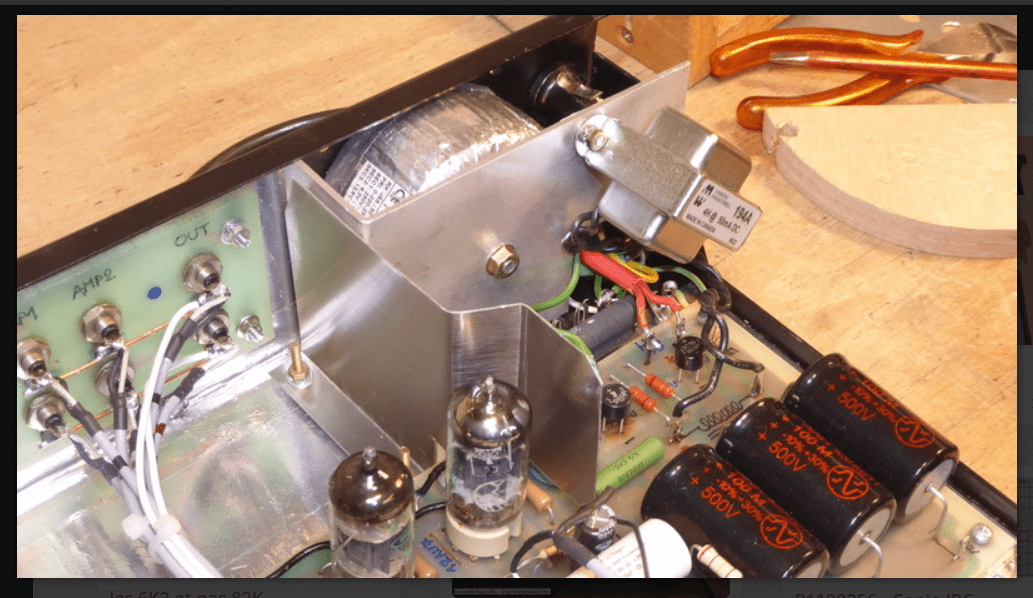

So I went for this solution below :

The EI PSU transformer has been suitably orientated for minimum influence, plus I installed two 3mm thick aluminium "wings" to cut the magnetic radiation from the core. I also installed a copper flux band around the winding to prevent electrical radiation.

Result : complete eradication of the noises, no more influence on the circuits, on the speaker or on any guitar, no matter the amp settings !

So yes, aluminium is efficient against hum and buzz radiations... Despite what many people say !

Another successfull example below, this time about a tube line/phono preamplifier - more in your field of application, @myleftear :

I firstly installed the toroidal transformer without special precautions, but nonetheless as far as possible of the circuits. Again : welcome to the unbearable hum and buzz world !

C'est bon, cette fois j'ai compris... Then :

The toroidal transformer is primarily encapsulated with 3 layers of aluminium conductive-adhesive foil, then placed behind a 2mm aluminium screen, plus an additional separation 0.5mm screen between the supply and the output tubes, all grounded. The chassis base, back and frontface bottoms have been covered with the same adhesive aluminium foil, in order to offer a continuous ground plane :

Doing this : I took great care not to short the transformer by the center screw and the aluminium shield, by creating a short-circuit buckle or turn.

Result : dead quiet preamp at any setting, complete eradication of any hum and buzzz... So yes again : aluminium is effective against perturbations.

In my next tube preamp build, I will go for the double boxing solution : the audio circuit will be completely encased in an inside Hammond aluminium box, with just the tubes protruding on their sockets and tubular locking shieldings. And for the PSU transformer, at least there will be screens if not a complete encasing.

T

Last edited:

woah, tres cool, @tubelectron ! fascinating, makes me hope I'll end up with hum to experiment with shielding

It seems as if hum prevention / shielding is just as complex as anything else 'lectronics.

(Of course I'd prefer not to have any hum, hehe...)

It seems as if hum prevention / shielding is just as complex as anything else 'lectronics.

(Of course I'd prefer not to have any hum, hehe...)

woah, tres cool, @tubelectron ! fascinating, makes me hope I'll end up with hum to experiment with shielding

It seems as if hum prevention / shielding is just as complex as anything else 'lectronics.

(Of course I'd prefer not to have any hum, hehe...)

Yes @myleftear. That said, it is more easy to take that problem in count when designing the project, than solving it afterwards...

Furthermore, Aluminium is easy to work, available in numerous formats, thicknesses and boxes, plus it is efficient against electrostatic and also magnetic radiations : I made myself a pertinent demonstration.

For those who still think that I am a fool, I'll take another example : my Micro-Preamp , a small Solid-State unit...

As you can see below, there's an Aluminium 2mm shielding that divide the small Aluminium casing in two parts :

A the start, this screen doesn't existed. I only relied on the fact that it was a SS circuit and that the transformer was far enough away from the circuit. But as is, there was still a light hummandbuzz remaining.

So I added that 2mm aluminium shielding as shown above and Voilà, Merci, Au Revoir : no more noise disturbance, dead quiet operation.

T

Over the years I have come over a huge number of hum and buzz problems. Sometimes the solution to finall get anything quiet, was against any common physics or at least electonical rules. In the end only the method giving you silence counts.

The fact, that you found a solution by try and error that works for you, doesn't mean you understood the problem. That is something many "experienced" people don't understand. You can't make rules from single observations.

An osciloscope with a simple coil as a probe can often find the cause for electromagnetic radiation. If you know the source it is much simpler to find a cure.

The fact, that you found a solution by try and error that works for you, doesn't mean you understood the problem. That is something many "experienced" people don't understand. You can't make rules from single observations.

An osciloscope with a simple coil as a probe can often find the cause for electromagnetic radiation. If you know the source it is much simpler to find a cure.

If you have an electromagnetic field changing polarity (50-60Hz), you can easily induce a current in a wire you bring near it. If you put an aluminum plate between it and the transformer, the current will be induced into the plate and be unable to reach the wire. Copper and aluminum are used in transformers because they transmitt this energy well. You don't use iron wires because of their high resistance.

Even thin aluminum foil works well. I have a roof insulation with rockwool on an aluminum foil. It screens any electromagnetic radiation from mains wires underneath it. In my case it makes my expensive wire and stud finder 100% useless, giving quite some problems with fault finding.

Even thin aluminum foil works well. I have a roof insulation with rockwool on an aluminum foil. It screens any electromagnetic radiation from mains wires underneath it. In my case it makes my expensive wire and stud finder 100% useless, giving quite some problems with fault finding.

The raw magnetic blocking capacity of aluminum at 50Hz is tiny for reasonable thicknesses (but it will improve for higher harmonics), but other effects come into play.

A conductive chassis frame can be neutral, attenuate slightly the hum or even transport it to distant locations: here is an extreme (and made-up) example of the effect:

https://www.diyaudio.com/community/...r-hum-problems-the-humboy.378178/post-6816214

By contrast, a relatively modest shorting plate or piece can easily shunt away most of these rogue circulating currents. The devil is in the details

A conductive chassis frame can be neutral, attenuate slightly the hum or even transport it to distant locations: here is an extreme (and made-up) example of the effect:

https://www.diyaudio.com/community/...r-hum-problems-the-humboy.378178/post-6816214

By contrast, a relatively modest shorting plate or piece can easily shunt away most of these rogue circulating currents. The devil is in the details

Yes I thought about this too. Even the much acclaimed shielding gear from don-audio ( https://www.don-audio.com/trafo-abschirmung-magnetfeld-abschirmblech , https://www.don-audio.com/Trafo-Shielding-Plate_1 ) is made of some iron, not mu. As I understand it, mu-metal cannot be worked (bent, cut, or anything mechanic) without losing its shielding properties, so it’s too complicated.

Found some easier shielding material at mouser, but don’t yet know wether it’s really what I might meed…)

Found some easier shielding material at mouser, but don’t yet know wether it’s really what I might meed…)

Elvee, thank you for this. I must say this overwhelms me at the moment. This Humboy is just another level, I‘m reading in the thread with my mouth open, like, to cite good MJ, „ahhhhh“…By contrast, a relatively modest shorting plate or piece can easily shunt away most of these rogue circulating currents. The devil is in the details

But, about these circulating currents, I assume they occur by the chassis picking up some radiation? And the, the shorting plate would be a sheet of (something) between transformer and its surrounding?

@tubelectron lovely builds! Would you happen to have any pictures of the fluxbands you created for the EI type transformer you mentioned?

@tubelectron lovely builds! Would you happen to have any pictures of the fluxbands you created for the EI type transformer you mentioned?

Thanks @WntrMute2 ! Here you are :

I experimented µmetal also : I lost my money and my time for null result...

Only the aluminium proved efficient :

The fact, that you found a solution by try and error that works for you, doesn't mean you understood the problem. That is something many "experienced" people don't understand. You can't make rules from single observations.

No pictures ? Never existed. Plus are you questioning the "experience" of the ALSTOM Transformer Division ? I never believe about forum improvised tribunes that want to give you lessons.

An osciloscope with a simple coil as a probe can often find the cause for electromagnetic radiation. If you know the source it is much simpler to find a cure.

Thank you. I already practice that method for a long time, and not with a simple coil. I am not neophyte.

T

The stray fields generated by the transformer cause eddy currents in every part of metal around. When the transformer is just mounted on a plain, uniform conductive plate, like aluminum, the eddy currents die away relatively quickly, and so do the secondary fields and disturbances they cause (must be something like the inverse of the cube of the distance or even -4th power, I don't remember).But, about these circulating currents, I assume they occur by the chassis picking up some radiation?

However the mounting plate and various accessories are rarely uniform and homogeneous, and this can funnel the disturbances in a precise direction, with a surprising intensity, as the demo setup shows.

To have ~500mA of eddy currents generated by such a relatively small transformer, you would have to be seriously unlucky, but only one tenth of that is already sufficient to ruin your day and your listening experience.

Note that although free-floating random pieces of 1 to 3mm aluminum have a relatively small effect on 50/60Hz fields, they will cause some distortion/deflection of the pattern, and if you are lucky you can have a small zone of cancellation happening to cover just the sensitive area you want to protect.

You cannot rely on luck or deterministic methods to achieve such a result: it is too improbable or complicated, like most magnetic problems. You need to experiment a lot, moving various parts in a convergent way, to end up with an acceptable result.

Of course, there is the proven, brute force method: first, distance, distance, distance, and then heavy mumetal shielding, for both the perturbator (transformer) and victim (sensitive circuit), but it is costly and requires tailor-made shields

- Home

- Design & Build

- Construction Tips

- Shielding circuits / transformers (another one) 🙄