Selenium HM17-25

The Datasheet

Interesting horn, this Selenium. It looks like a nice, cheap way of getting a smoothly terminated horn without a diffraction slot, basically an adapted JBL 2404 with the dispersion characteristic traded for smoother throat contouring. I've not seen these used in any projects, but have ordered a quad for testing (I plan to hack 2 of them to get the driver mounting piece for use in DIY OS waveguides).

Anyone have any thoughts on this itty-bitty bi-radial? With a little care, it looks to be a very good candidate for a geddes-styled 2-way with a 12", XO at 2.5k.

The Datasheet

Interesting horn, this Selenium. It looks like a nice, cheap way of getting a smoothly terminated horn without a diffraction slot, basically an adapted JBL 2404 with the dispersion characteristic traded for smoother throat contouring. I've not seen these used in any projects, but have ordered a quad for testing (I plan to hack 2 of them to get the driver mounting piece for use in DIY OS waveguides).

Anyone have any thoughts on this itty-bitty bi-radial? With a little care, it looks to be a very good candidate for a geddes-styled 2-way with a 12", XO at 2.5k.

Last edited:

Maybe this you will find helpful. Polars per 10deg, 1/3oct smoothed. No idea about any 12" reaching 2K5 without serious break-up issues.

The horn is problematic in the back (to be airtight) against the box. Not a flat surface. I'm using it in a 3-way.

Last edited:

The 17-25 sounds really nice in the horizontal plane. Go up or down, and it goes south in a hurry. The 25-25 metal horn degrades a bit more gracefully on the vertical axis, but won't get up as high regardless of the driver used.

In either case, they work better paired with 10's than 12's when crossed at 2-2.5k.

Wolf (from the PE board) has used the 17-25 and thought well enough of them to pair them with some really expensive Morel midranges. I think he used the cheap Selenium driver, too.

In either case, they work better paired with 10's than 12's when crossed at 2-2.5k.

Wolf (from the PE board) has used the 17-25 and thought well enough of them to pair them with some really expensive Morel midranges. I think he used the cheap Selenium driver, too.

I've had these for years. Driven with the Selem D210Ti. Not bad.

Strange frequency response at the top, but that may be the driver.

I did modify mine a little. I filed down the ridge in the throat at the start of the horn flare. Removed the bug screens from the driver. Used putty to fill the gap between the horn throat and the the driver throat. As mine don't screw all the way in, there is a nasty gap.

Guess I should post before and after measurements to see if there is any merit to my mods. 😀

Strange frequency response at the top, but that may be the driver.

I did modify mine a little. I filed down the ridge in the throat at the start of the horn flare. Removed the bug screens from the driver. Used putty to fill the gap between the horn throat and the the driver throat. As mine don't screw all the way in, there is a nasty gap.

Guess I should post before and after measurements to see if there is any merit to my mods. 😀

Maybe this you will find helpful. Polars per 10deg, 1/3oct smoothed. No idea about any 12" reaching 2K5 without serious break-up issues.

Wow, yes, that's extremely helpful! Very nice polars. Looks like 1k5 IS a viable crossover target, assuming a very steep applied slope. I was thinking 2k5 as I was assuming such a small horn to have very limited pattern control at the lower end, looks like the tight pattern works better than I thought.

It would indeed be interesting to see your before and after, pano. I'm enthusiastic about trying this horn now 🙂

Wow, yes, that's extremely helpful! Very nice polars. Looks like 1k5 IS a viable crossover target, assuming a very steep applied slope. I was thinking 2k5 as I was assuming such a small horn to have very limited pattern control at the lower end, looks like the tight pattern works better than I thougt.

It is smaller because it relies on edge diffraction. Take care, polars are 1/3oct. smoothed, so don't expect world-class performance.

It is smaller because it relies on edge diffraction. Take care, polars are 1/3oct. smoothed, so don't expect world-class performance.

It doesn't seem to have any throat roughness in the examples I have here, which is BONUS!

I've had these for years. Driven with the Selem D210Ti. Not bad.

Strange frequency response at the top, but that may be the driver.

I did modify mine a little. I filed down the ridge in the throat at the start of the horn flare. Removed the bug screens from the driver. Used putty to fill the gap between the horn throat and the the driver throat. As mine don't screw all the way in, there is a nasty gap.

Guess I should post before and after measurements to see if there is any merit to my mods. 😀

That ridge seems to have likely been an apparent ridge, if the ones I have are any indication- apparent in that it was there because of the gap between driver and horn.

By edge diffraction I meant mouth diffraction

Definitely true, and one sees it around the cutoff in the CSD. I plan to improve mouth termination at least somewhat, but per geddes, the throat is the far more problematic area, at least from avoiding 'horniness'. A little periphery felt should be a good start.

We'll see, hopefully I can get it singing. The hard parts are done well (good polars, smooth throat), so the fiddly stuff may be able to get resolved without too much trouble. I'll report back!

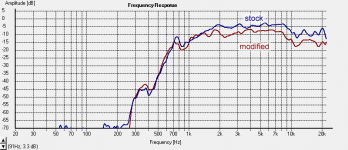

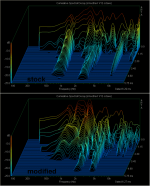

I did some measurements of my horns before and after modification.

Posted below are on axis FR and CSD. From the look of it, I made them worse!

Mostly what I did was remove the bug screen and smooth the transition from driver to horn throat.

Tho there was a couple of week between the measurements, I did my best to duplicate the original setup. Not sure I succeeded.

I dunno, what do you think?

Posted below are on axis FR and CSD. From the look of it, I made them worse!

Mostly what I did was remove the bug screen and smooth the transition from driver to horn throat.

Tho there was a couple of week between the measurements, I did my best to duplicate the original setup. Not sure I succeeded.

I dunno, what do you think?

Attachments

...

Mostly what I did was remove the bug screen and smooth the transition from driver to horn throat.

...

Mentally, I almost can not accept these would harm. Just can't imagine.

So, how's the sound to you?

Hard to tell. Since I'm crossing them at about 5.5Khz. But they sure don't sound worse.

Oh BTW, those measurements are at 50cm.

Oh BTW, those measurements are at 50cm.

I don't accept the concept of a throat diffraction in this waveguide. Its too narrow

on both sides of the bug screen discontinuity to support tangential high order modes.

(unless we consider the ultrasonic frequencies relevant).

There are certainly standing waves in the primary mode with any discontinuity of

impedance, ridge, or screen in the throat. But a disturbance of the primary mode

alone does not constitute the acoustic equivalent of the optical effect "diffraction".

A diffraction causes a diffraction pattern. And this can't occour where the guide

itself is smaller than the central spot of such a pattern. Any such pattern is still

just a single fuzzy "spot" that flows to fill up the entire width of the waveguide.

I think this word gets misused sometimes.

Diffractions do occur at the mouth end, and in the throats of those horns with

very abrupt expansion to width that can actually support a diffraction pattern or

tangential high order mode. But what happens at the bug screen in a throat that

is narrower than the cutoff of every possible high order mode? Is something else

that probably deserves a different name. I don't know what that would be...

An Iris maybe? I think thats how I've heard it described in microwave waveguides...

Its definately a lumped element with a complex effect upon frequency response,

reflected power, and impedance. But negligible in diffractive effect. The dispersion

pattern remains unchanged.

on both sides of the bug screen discontinuity to support tangential high order modes.

(unless we consider the ultrasonic frequencies relevant).

There are certainly standing waves in the primary mode with any discontinuity of

impedance, ridge, or screen in the throat. But a disturbance of the primary mode

alone does not constitute the acoustic equivalent of the optical effect "diffraction".

A diffraction causes a diffraction pattern. And this can't occour where the guide

itself is smaller than the central spot of such a pattern. Any such pattern is still

just a single fuzzy "spot" that flows to fill up the entire width of the waveguide.

I think this word gets misused sometimes.

Diffractions do occur at the mouth end, and in the throats of those horns with

very abrupt expansion to width that can actually support a diffraction pattern or

tangential high order mode. But what happens at the bug screen in a throat that

is narrower than the cutoff of every possible high order mode? Is something else

that probably deserves a different name. I don't know what that would be...

An Iris maybe? I think thats how I've heard it described in microwave waveguides...

Its definately a lumped element with a complex effect upon frequency response,

reflected power, and impedance. But negligible in diffractive effect. The dispersion

pattern remains unchanged.

Last edited:

I did some measurements of my horns before and after modification.

Posted below are on axis FR and CSD. From the look of it, I made them worse!

Mostly what I did was remove the bug screen and smooth the transition from driver to horn throat.

Hmm... I was going to try this later this week. Feeling a little gun shy now.

Well everything I did was reversible expect a little filing in the horn throat. And I only did that on one horn as the other seemed OK.

So maybe I'll remove the putty, put the bug screens back in and do the measurements all over. Easy to do.

So maybe I'll remove the putty, put the bug screens back in and do the measurements all over. Easy to do.

Well everything I did was reversible expect a little filing in the horn throat. And I only did that on one horn as the other seemed OK.

So maybe I'll remove the putty, put the bug screens back in and do the measurements all over. Easy to do.

Interesting pano. I almost pestered you earlier today. I've had waveguides on the brain- I'm trying to do geddes-style OS waveguides using the parts express 12" waveguide as a base.....

Hint to others.... don't bother... I'm half a dozen materials in and it ain't done yet..... but should be nice when it is.

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Selenium HM17-25