I guess it is just me then, I fill the entire cut when I cut a kerf like that even with ply. I want it solid.

Yes, I wrote that rather quickly didn't I? Let me try again.

You don't need to fill the kerf completely, as when you bend it, some of the glue will be wasted as it squeezes out.

Thanks for the clarification there Cal. I was thinking of filling the kerf after it was assembled but your idea works well also, probably a lot easier that way than having to fill after the fact.

And ThyDntWntMusic, the fiberglass will go a long way to cover the problems of broken mdf, just let some resin seep into the cracks when doing the layup and you are gold.....

You can also make a template from the curve after you form it or us a radius gauge to find out what you actually ended up with. It would be easy to transfer that to a brace to fit your curve whatever it came out to be, doesn't have to be perfectly round.

And ThyDntWntMusic, the fiberglass will go a long way to cover the problems of broken mdf, just let some resin seep into the cracks when doing the layup and you are gold.....

You can also make a template from the curve after you form it or us a radius gauge to find out what you actually ended up with. It would be easy to transfer that to a brace to fit your curve whatever it came out to be, doesn't have to be perfectly round.

It hasn't cracked... yet, nailing and gluing would never hold when there's 4,000 - 6,000watts being put into it.

I think I would have trouble keeping the glass in the car with 4-6K watts of power on the bottom end!

6 kW, no glass problems.I think I would have trouble keeping the glass in the car with 4-6K watts of power on the bottom end!

A Diesel car engine powered sub can do some damage though 😉.

MythBusters subwoofer - YouTube

Shakin' it, 160 dB at 16 Hz!

Kerfing MDF? Maybe I am missing something but that is something I would not consider.

Did it work for anyone? What radius?!

It's been done plenty of times. For a speaker that won't travel too much it'll be okay with some sort of bonding / epoxy / resin on it.

For a speaker that will see road duty I wouldn't trust it, not would I use MDF to begin with.

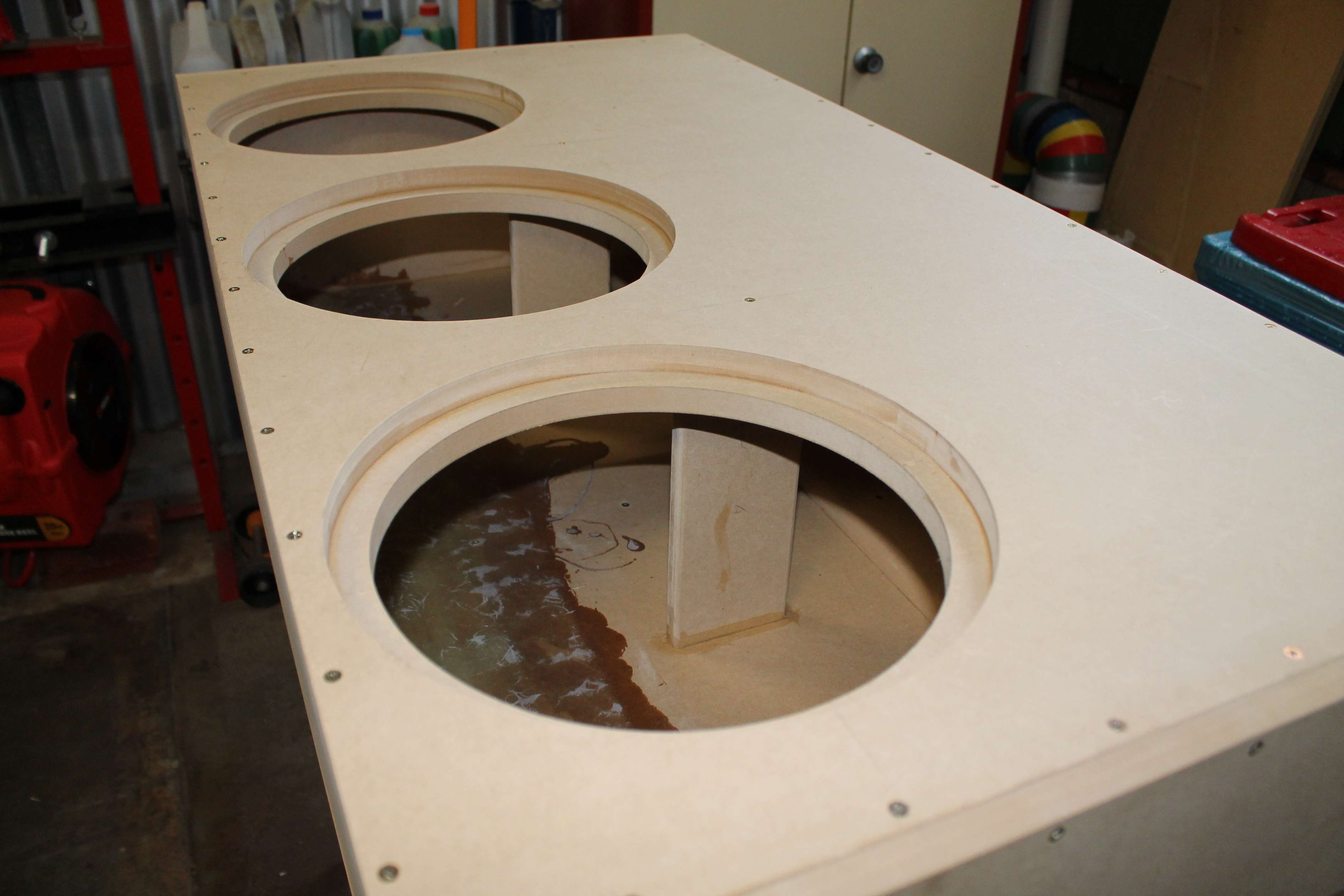

That looks great! Good work

Thanks 😉 Its in the guys car now, and it fitted, which was good!

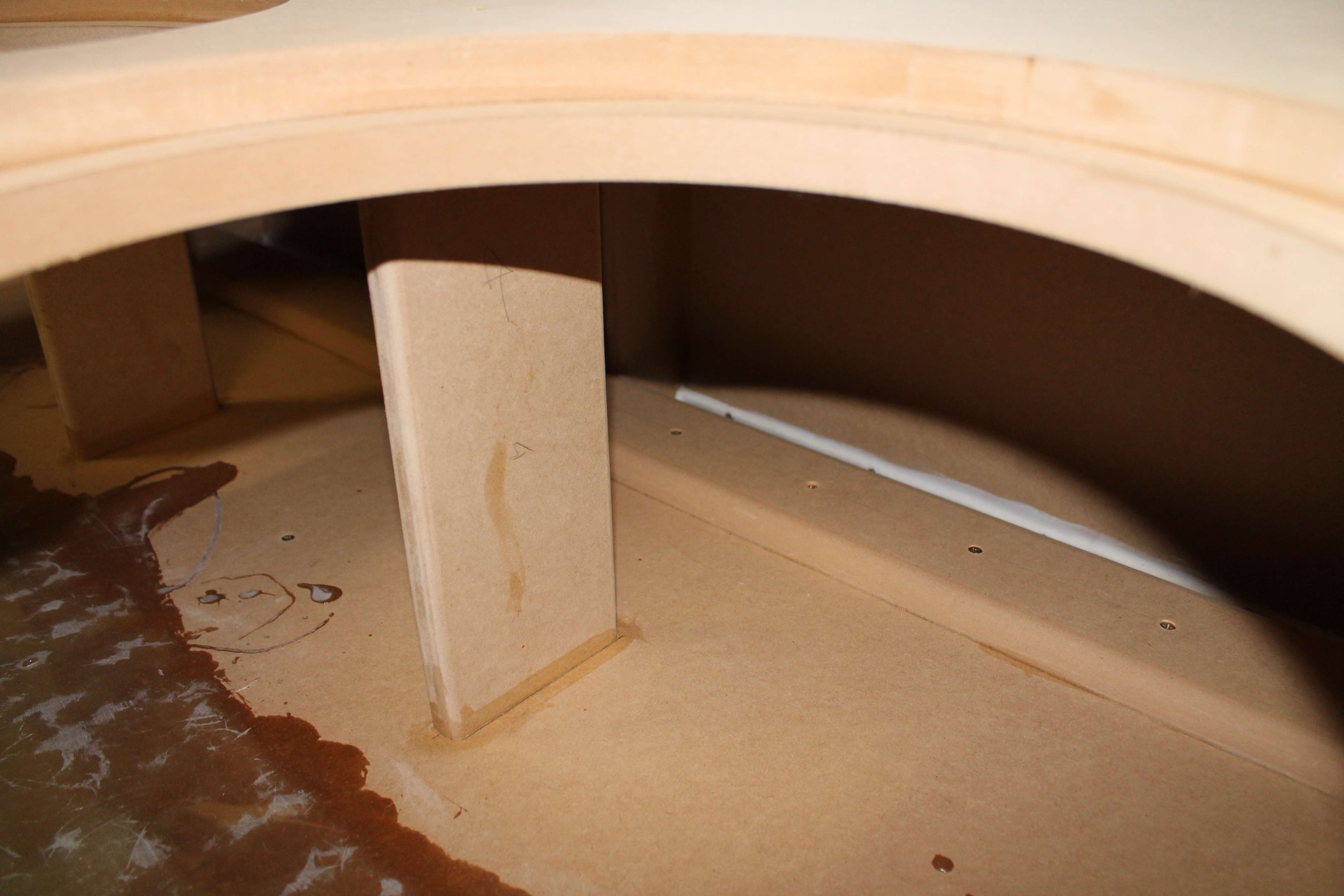

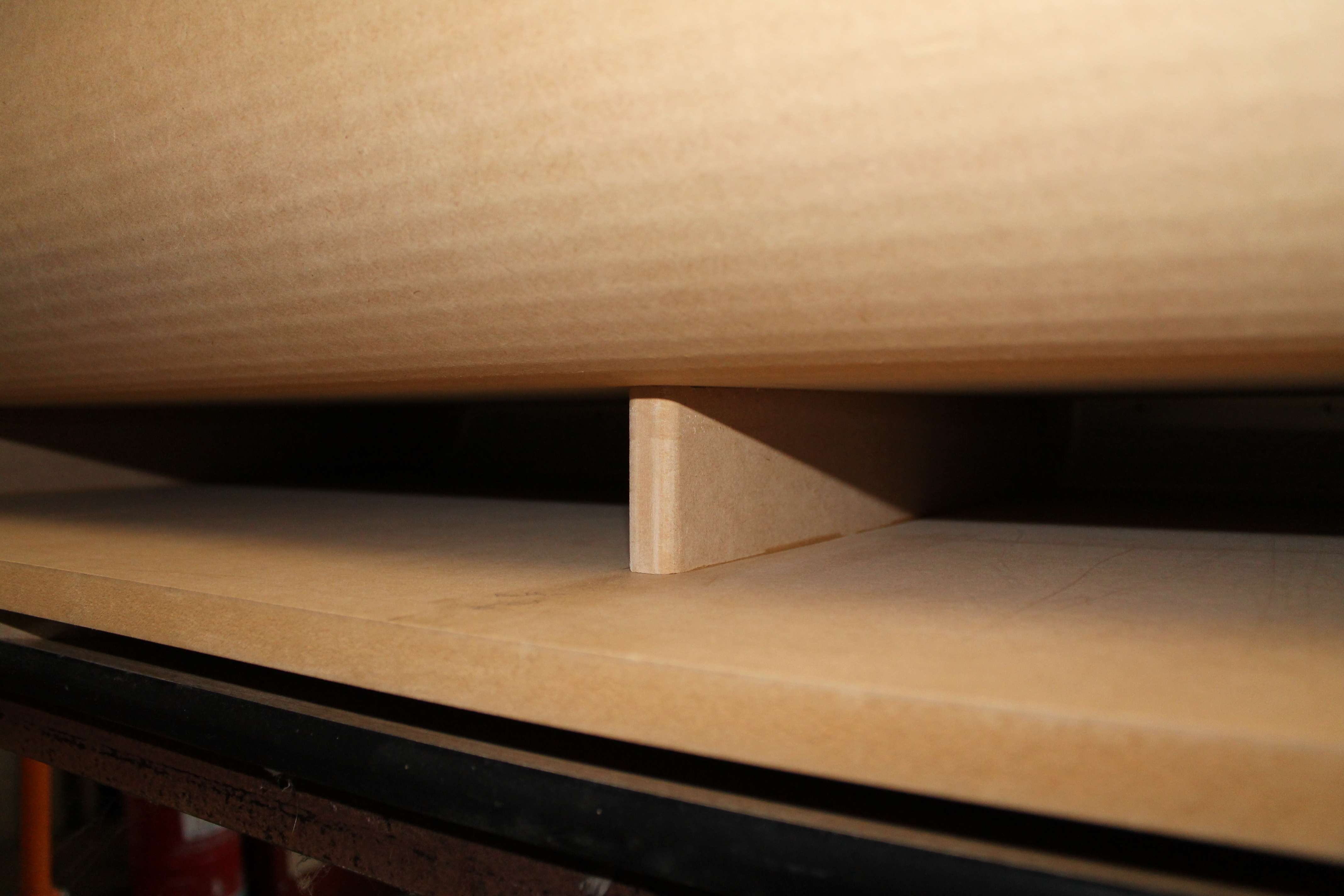

Are the kerf cuts going on the inside or the outside of the bend? That should make a whale of a difference.

They are on the inside, what's the difference?Are the kerf cuts going on the inside or the outside of the bend? That should make a whale of a difference.

Inside:

From what I've seen here in Australia they've been making pre-fab mdf boxes with kerfing bends for years now!

Kudos to ThyDntWntMusic for those boxes, you definately have a gift mate and your in it...

For the other Fellas, do you normally use ply for sub or speaker boxes and if so why? I know ply is cheaper here in Aus but unless going to very very large sizes I dont generally see it being used!

Great forum btw... 🙂

Kudos to ThyDntWntMusic for those boxes, you definately have a gift mate and your in it...

For the other Fellas, do you normally use ply for sub or speaker boxes and if so why? I know ply is cheaper here in Aus but unless going to very very large sizes I dont generally see it being used!

Great forum btw... 🙂

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Subwoofers

- Saw blade for kerfing MDF?