Space the damping out from the wall and its effective absorption goes down in frequency.

For a given thickness and density wool felt does about as well as any other porous material. I've seen no data that suggests melamine foam is any better in this respect.

For a given thickness and density wool felt does about as well as any other porous material. I've seen no data that suggests melamine foam is any better in this respect.

I've been using wool felt on walls specifically, and that itchy fiberglass stuff in-between. Works better in this combination than each of them separately.

Documented somewhere in my huge thread by the way. With measurements. I tried several materials and cannot agree that wool felt would be

a bad choice or that it would work well for high frequency only. By itself on walls alone it does quite a lot already to damp the visible impedance peaks.

In combination with fiberglass it worked best for the whole spectrum. I've also have a layer of felt between the driver and that itchy stuff.

Even in my (sealed) subwoofer build, the results got better when I used a combination of these two materials. Impedance plots will show it.

Documented somewhere in my huge thread by the way. With measurements. I tried several materials and cannot agree that wool felt would be

a bad choice or that it would work well for high frequency only. By itself on walls alone it does quite a lot already to damp the visible impedance peaks.

In combination with fiberglass it worked best for the whole spectrum. I've also have a layer of felt between the driver and that itchy stuff.

Even in my (sealed) subwoofer build, the results got better when I used a combination of these two materials. Impedance plots will show it.

I've tested a lot of these materials here: https://www.somasonus.net/box-construction-methods. I did not use wool felt, but wool batting for quilts. Great stuff. Also tested were melamine and SonicBarrier.I've seen no data either - that is the problem🙂

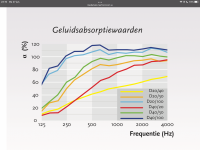

From the first serious research hit I found. Felt 10mm, density some 160kg/m3. Impedance tube measurement, so not corrected for diffuse sound field. Below 1kHz not really impressive (pun intended). What’s more: even applied with an air gap it doesn’t do much below 1kHz. The stuff just is too dense.

Compare this to any good acoustic fiber or foam, like aforementioned basotect.

A moderate layer of 50mm on boundary and density 20kg/m3 does about 3 times as much at 1kHz. But what’s more: it is a lot more effective at lower frequencies. And there you need the stuff, not at tweeter frequencies. Such research stuff is readily available and pretty common knowledge between acousticians BTW, I don’t know why it wouldn’t drop down here.

I figured that, after re-reading your post. Normal undercarpet felt doesn’t do either damping very good. Too dense for sound absorption in air and too light for damping any panel resonance. It’s not that it doesn’t do anything, but I only suggested saving yourself the trouble.This damping is about wall plates surface vibes.

Internal waves damping of hollow space (rear soundwaves from driver) in front of cardiode slots will be PET based (40 kg/m3) from HVAC sound attenuator industry.

Hardly a like for like comparison!From the first serious research hit I found. Felt 10mm, density some 160kg/m3. Impedance tube measurement, so not corrected for diffuse sound field. Below 1kHz not really impressive (pun intended). What’s more: even applied with an air gap it doesn’t do much below 1kHz.

A moderate layer of 50mm on boundary and density 20kg/m3 does about 3 times as much at 1kHz.

50mm of wool felt around 35Kg/m3 will likely perform about the same as the basotect.

Last edited:

Air core (wooden core) inductor wound down from16 to 15 mH. Coil weight is approx 4.5kg (2.2 lbs)

The coil is very tightly wound and now vulcanized after the adjustment. There should be very little problems as microphonics, hysteresis and resistance.

0.87 ohm at 15 mH

The coil is very tightly wound and now vulcanized after the adjustment. There should be very little problems as microphonics, hysteresis and resistance.

0.87 ohm at 15 mH

Attachments

Pre-assembly, awaiting the hexagon grid for the slots. View: Front & rear w/ subs Hypex 503 & rear tweeter.

- Home

- Loudspeakers

- Multi-Way

- Satori TX in line array "Moelva"