Each panel is filled as they are made then a top off hole is dirlled in each one. A small gap at the top edge of a panel will not be a deaster, but for neatness and peace of mind topping off the panels is nice.

Care to elaborate? Is a materials dampening properties variable to pressure level / frequency?The sand will be ineffective in a subwoofer application.

I thought compacted sand would just unifie the box as does a peice of bracing. And again if I compact the sand, must it be dense or not and could we just use flour?

Vikash said:

Care to elaborate? Is a materials dampening properties variable to pressure level / frequency?

related to :

The sand will be ineffective in a subwoofer application.

no problem :

All forms of layer damping rely on one basic principle,

the layers must move for the damping to be effective.

In a two way speaker layer damping allows you to damp

the panel resonances of the box allowing clean midrange.

To effectively damp the panels you always end up with panel

resonances an octave or more below the high Q resonances

of a solid panel construction, the panels are less stiff.

(if you add bracing to the solid panel perhaps two octaves)

At low frequencies below panel resonances the stiffness of the

box determines its acoustic output, damping is not important.

Its far better (as Ron E also said) to comprehensively brace

the box, maximizing stiffness, minimizing low frequency output,

and pushing up the panel resonances well beyond the high

frequency cut off point of the subwoofer.

Even with gentle crossover slopes an eventual high slope is

good for minimizing excitation of midrange resonances.

The above approach will give cleaner low bass, is cheaper to

make, takes up far less volume (a 35 litre box with 42mm walls

will have an external volume of at least 70 litres ! - half of it will

be material not airspace), and good c/o arrangements take care

of the minor panel resonance issues.

🙂 sreten.

As a soon to be geotechnical engineer Ive some remarks on the sand filling. The sand have to be loosely packed to have effect, ( interaction between the grain particles) otherwise no energy will be dissipated. If the sand is compacted less energy will be dissipated.

LaMa said:As a soon to be geotechnical engineer Ive some remarks on the sand filling. The sand have to be loosely packed to have effect, ( interaction between the grain particles) otherwise no energy will be dissipated. If the sand is compacted less energy will be dissipated.

Yes, you want the sand to move to absorb the energy.

Flour, as mentioned would be to light to absorb much energy. Lead shot is also good for this use.

Why? Just keep putting in sand until there is no more room at the top and it will eventually find its way into all spaces.Guss said:With an hole at the top of the box the sand would spread unequally into the gap.

Re: Another wall of thought

Different aim. That would raise resonant freq, not absorb energy. It is a good idea to have the resonance high above the cut-off freq. Why not do both!Lee35210 said:I have been toying with the idea of using ceramic tile backer board/mdf/plywood sandwich for a sub cabinet. Any thoughts or experience with this?

Lead sandwich...Yum

I have recently finished my enclosure which are a sandwich of 4 layers of cheap laminated wood with a thin sheet of lead. I will put photos soon.

http://www.diyaudio.com/forums/showthread.php?threadid=21794

Anyway, although it is a pain to build, i really like the result. The lead really add mass and stability to the structure. Mass is an important parameter for me in a good enclosure.

I like the idea of sand sandwich but after a while, the sand will pack up and be less effective. But the added mass is still an advantage. Since lead is more heavy, an enclosure with lead sheets may be heavier and smaller which i guess is always good.

F

I have recently finished my enclosure which are a sandwich of 4 layers of cheap laminated wood with a thin sheet of lead. I will put photos soon.

http://www.diyaudio.com/forums/showthread.php?threadid=21794

Anyway, although it is a pain to build, i really like the result. The lead really add mass and stability to the structure. Mass is an important parameter for me in a good enclosure.

I like the idea of sand sandwich but after a while, the sand will pack up and be less effective. But the added mass is still an advantage. Since lead is more heavy, an enclosure with lead sheets may be heavier and smaller which i guess is always good.

F

For what it's worth I've had good results using sand for damping: here's a trick which takes a lot of the faff out of using it.

Get some twin wall polycarbonate roofing sheet. Tape the ends with something suitable. (NOT cellophane tape it biodegrades and has an alarming electret effect which makes all the sand jump out at it!)Fill the channels with sand and seal.

Attach to the enclosure panels with a lossy adhesive. Works a treat.

However I do think it's a waste of time for a sub. In my experience stiffness is all for bass quality. Any panel resonances should move out of the passband if it's stiff enough.

Go for good quality birch throughout ply and brace it to death, MDF has typically half the stiffness of good ply. Use locked routed joints. Don't screw and glue butt joins, it does make a difference.

Good luck,

Simon

Get some twin wall polycarbonate roofing sheet. Tape the ends with something suitable. (NOT cellophane tape it biodegrades and has an alarming electret effect which makes all the sand jump out at it!)Fill the channels with sand and seal.

Attach to the enclosure panels with a lossy adhesive. Works a treat.

However I do think it's a waste of time for a sub. In my experience stiffness is all for bass quality. Any panel resonances should move out of the passband if it's stiff enough.

Go for good quality birch throughout ply and brace it to death, MDF has typically half the stiffness of good ply. Use locked routed joints. Don't screw and glue butt joins, it does make a difference.

Good luck,

Simon

Hi, Sand can be a very good technique for panel dampening. The granules vibrate converting energy into heat. No new news there. But its complicated getting the correct density (whatever that is?) between the panels and its messy. If you do use sand make sure it is baked at low temps to throughly kill anything in it and to have it perfectly dry. Tony Gee has used sand in his Flexy Rack system and details everything on his site here... http://home.hetnet.nl/~geenius/Flexy.html Personally I like to use constrained layer dampening using a viscoelastic sheet made of Swedac specifically designed for this. Their glue has dampening properties also. For the inside of my cabinets I use the Swedac glue to bond ceramic tiles. Theres many different ways to accomplish the same thing. I like layering 1/2" HDF, Swedac sheet, 1/2" MDF or BB and then bond the ceramic tiles. HTH-Brian Oh Swedac is found here... http://www.swedac-acoustic.se/pages/vibra.damp.htm

Thanks for all the replies.

Considering these are two high excursion drivers in a small box (i.e. a lot of movement), I'm thinking about using 8 threaded rods going all the way through the enclosure (and a couple of shelf braces) and through the mounting holes of each driver. Any comments?

I also want to use one of the shelf braces with a suitable hole cut through its center to firmly grip the magnet structure of the active driver. I'm in mixed minds whether this will be of significant benefit?

Also, does steel threaded rod require damping in a sub application?

Considering these are two high excursion drivers in a small box (i.e. a lot of movement), I'm thinking about using 8 threaded rods going all the way through the enclosure (and a couple of shelf braces) and through the mounting holes of each driver. Any comments?

I also want to use one of the shelf braces with a suitable hole cut through its center to firmly grip the magnet structure of the active driver. I'm in mixed minds whether this will be of significant benefit?

Also, does steel threaded rod require damping in a sub application?

Hi, I was considering using threaded steel rod in my next cabinet. Initially I was just going to use it as bracing, but now Im thinking of having the steel rod go thru a steel or AL pipe inside the cabinet and have a steel plate on the outside cabinet wall. Then I could experiment with tightening down the bolts onto the steel plate to see if different tensions had any effect on cabinet vibration. Something like 5 or 6 of these clamps per cabinet? Im wondering if the steel pipe should be filled with expandable foam? -Brian

Guys,

I reckon that there are two major factors at play here. One is the mechanical reaction of the motor system trying to move the driver the opposite direction to it's excursion. This travels through the enclosure structure and will energise anything that can move. So opposing drivers will help to cancel this. Using tie rods to couple the drivers together should further reduce the amount of vibration going into the enclosure by decreasing the moment from motor reaction. Again bracing the magnets could help but this is tricky to do properly, as the mechanical coupling has to be first class to do anything useful.

The other factor is the change in internal air pressure in response to the drivers movement. This will flex any areas that are free to move. (including the driver's diaphragm)

And they don't need to go far to be plainly audible. Just look at the relationship between driver and box surface area, if the driver has to move say, 10mm how far does the box need to move to match the drivers displacement? - we're talking micrometres!

If you go ahead with rods (At least M10 I reckon)I shouldn't damping is an issue. Given that they are in the enclosure there will be almost no radiation given the small surface area and the narrow frequency passband. The speed of sound through steel is really high, any vibration will be most strongly coupled to the other end of the rod! Test the assembly for ringing out of the enclosure if you really want to be sure. I'd go for stainless too, there could be magnetic coupling issues that might degrade the driver's performance.

Simon

I reckon that there are two major factors at play here. One is the mechanical reaction of the motor system trying to move the driver the opposite direction to it's excursion. This travels through the enclosure structure and will energise anything that can move. So opposing drivers will help to cancel this. Using tie rods to couple the drivers together should further reduce the amount of vibration going into the enclosure by decreasing the moment from motor reaction. Again bracing the magnets could help but this is tricky to do properly, as the mechanical coupling has to be first class to do anything useful.

The other factor is the change in internal air pressure in response to the drivers movement. This will flex any areas that are free to move. (including the driver's diaphragm)

And they don't need to go far to be plainly audible. Just look at the relationship between driver and box surface area, if the driver has to move say, 10mm how far does the box need to move to match the drivers displacement? - we're talking micrometres!

If you go ahead with rods (At least M10 I reckon)I shouldn't damping is an issue. Given that they are in the enclosure there will be almost no radiation given the small surface area and the narrow frequency passband. The speed of sound through steel is really high, any vibration will be most strongly coupled to the other end of the rod! Test the assembly for ringing out of the enclosure if you really want to be sure. I'd go for stainless too, there could be magnetic coupling issues that might degrade the driver's performance.

Simon

This sounds promising; I knew this is an advantage of the push-push configuration, but was unsure whether there would be similar benefits with a 1 active + 1 passive configuration as they're acting out-of-phase.One is the mechanical reaction of the motor system trying to move the driver the opposite direction to it's excursion. This travels through the enclosure structure and will energise anything that can move. So opposing drivers will help to cancel this.

The largest dia. rod that will fit through the mounting holes is 5mm.

I also assume there is a similar non-issue with mounting a passive opposite the active as there is with a port?

Hi Vikash,

Note that the force cancellation will only occur at PR resonance.

IMO the rods are not necessary.

Reinforcing the PR chassis is pointless. IMO for the driver at

the frequencies involved reinforcing its chassis is simply not

required either.

All you need IMO is a good bracing scheme.

🙂 sreten.

Note that the force cancellation will only occur at PR resonance.

IMO the rods are not necessary.

Reinforcing the PR chassis is pointless. IMO for the driver at

the frequencies involved reinforcing its chassis is simply not

required either.

All you need IMO is a good bracing scheme.

🙂 sreten.

I largely agree with sreten,

As your second driver is passive and not active you're not going to get much benefit from mechanical coupling as they will only be doing the same thing at resonance as sreten says.

M5 rod is way too skinny, you can bend it by hand dead easy, the enclosure will be an order of magnitude stiffer than the rod.

Bracing the magnet effectively without compromising the baffle driver fixing could bring some benefit I reckon, especially if the driver basket is not diecast. This requires absolute precision though, i.e no slop whatsoever at either interface otherwise you'll be worse off than fixing the driver as normal. It's that old action-reaction thing again

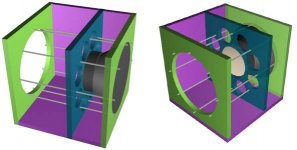

Nice drawing!

Simon

As your second driver is passive and not active you're not going to get much benefit from mechanical coupling as they will only be doing the same thing at resonance as sreten says.

M5 rod is way too skinny, you can bend it by hand dead easy, the enclosure will be an order of magnitude stiffer than the rod.

Bracing the magnet effectively without compromising the baffle driver fixing could bring some benefit I reckon, especially if the driver basket is not diecast. This requires absolute precision though, i.e no slop whatsoever at either interface otherwise you'll be worse off than fixing the driver as normal. It's that old action-reaction thing again

Nice drawing!

Simon

Perhaps a second PR is the way to go after all. This would mean that four of the of six enclosure walls will be taken (including amp) which is an aesthetic nightmare to my eyes. I see a coffee table sub as a way out...Note that the force cancellation will only occur at PR resonance.

Some more products of boredom...Nice drawing!

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Sand sandwich