Here are the beginnings of making a variation on the rubanoid design, inspired after reading the wonderful experiments of WrineX and sergiu2009, and then trying my own triple-segment version, which sounded amazing but was full of flaws. I have now decided on a greatly simplified design using a pair of transverse coils down one single cylindrical membrane - like the triple design with the two sides taken off.

The cylindrical membrane is laid in carbon fibre tissue, so keeps its shape even though it is very thin - weighs only 32grams with the two wire voice coils embedded, and will only get better as I work out how to lay in the epoxy next time....

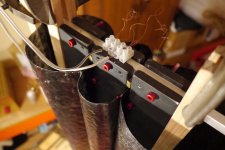

The basic design is to have voice coils down the length of either side of the cylinder, which is set within three strips of magnet bar (similar to all the rubanoid designs, but using 3 instead of 2). So I will have a (theoretically) uniformly driven membrane, that distributes the force nicely over the curved cross section. But we shall see - it may sound terrible!

This comes from my trial 3 section rubanoid, which worked as a trial, using similar 2 voice coils trapped between the middle membrane and each side. THIS IS THE OLD VERSION - THE NEW VERSION WILL BE ONLY THE CENTRE CYLINDER, changed in dimension and proportion....

This is my little video of it playing.

The membrane was far too heavy, very inefficient, but had amazing bass - real drum like beats so punchy and fast. Very directional.... Interesting sounding - compelling - and well worth the effort, but time to change some of the basic notions I think.

OLD DESIGN WITH 3 SECTIONS -

I think the new design with a single cylinder, driven pistonically, eliminates possible weird breakups as the vibrations move from the driven section to the stationary side wings that are characteristic of the rubanoid style. Maybe. I am just guessing with my own ideas. Whether it works or not, it will be a pain to get the membrane in and trap it between the magnet bars - I have some ideas about how to do this but it may be done completely differently while attempting.... And when it is done I shall hear if I have any idea of what I am talking about. : ) Fun.

Not having the wings means I need some other way of centreing the cylinder in the 5mm magnet gap, and I am trialling making long rubber roll surround - mould-making silicon impregated into open-weave fabric, set on a small hump mould to make the right shape, and then siliconed in place onto the membrane. This will add some weight to the moving mass, and the only other idea I have had is to suspend the cylinder between very thin wires of spring steel top and bottom. Not sure, but I have hopes for the rubber roll suspension. There will be 4 strips - front and back, both sides.

Next is making more rubber roll surrounds and attaching them to the membrane, and then seeing if I can position it within the magnet bar structure accurately just with the surrounds....

If anyone has any thoughts or suggestions, please let me know. I am good at making, and can think things through pretty well, but i can get caught up thinking only one specific thing, and all of a sudden, i am in the muddy gutter at the side of the road, tears down my face, and no idea how I got there. But hopefully these speakers are a very sunny trip in the country.

Thanks heaps to WrineX and sergiu2009 - you have inspired me to make something stupid that may not work!

The cylindrical membrane is laid in carbon fibre tissue, so keeps its shape even though it is very thin - weighs only 32grams with the two wire voice coils embedded, and will only get better as I work out how to lay in the epoxy next time....

The basic design is to have voice coils down the length of either side of the cylinder, which is set within three strips of magnet bar (similar to all the rubanoid designs, but using 3 instead of 2). So I will have a (theoretically) uniformly driven membrane, that distributes the force nicely over the curved cross section. But we shall see - it may sound terrible!

This comes from my trial 3 section rubanoid, which worked as a trial, using similar 2 voice coils trapped between the middle membrane and each side. THIS IS THE OLD VERSION - THE NEW VERSION WILL BE ONLY THE CENTRE CYLINDER, changed in dimension and proportion....

This is my little video of it playing.

The membrane was far too heavy, very inefficient, but had amazing bass - real drum like beats so punchy and fast. Very directional.... Interesting sounding - compelling - and well worth the effort, but time to change some of the basic notions I think.

OLD DESIGN WITH 3 SECTIONS -

I think the new design with a single cylinder, driven pistonically, eliminates possible weird breakups as the vibrations move from the driven section to the stationary side wings that are characteristic of the rubanoid style. Maybe. I am just guessing with my own ideas. Whether it works or not, it will be a pain to get the membrane in and trap it between the magnet bars - I have some ideas about how to do this but it may be done completely differently while attempting.... And when it is done I shall hear if I have any idea of what I am talking about. : ) Fun.

Not having the wings means I need some other way of centreing the cylinder in the 5mm magnet gap, and I am trialling making long rubber roll surround - mould-making silicon impregated into open-weave fabric, set on a small hump mould to make the right shape, and then siliconed in place onto the membrane. This will add some weight to the moving mass, and the only other idea I have had is to suspend the cylinder between very thin wires of spring steel top and bottom. Not sure, but I have hopes for the rubber roll suspension. There will be 4 strips - front and back, both sides.

Next is making more rubber roll surrounds and attaching them to the membrane, and then seeing if I can position it within the magnet bar structure accurately just with the surrounds....

If anyone has any thoughts or suggestions, please let me know. I am good at making, and can think things through pretty well, but i can get caught up thinking only one specific thing, and all of a sudden, i am in the muddy gutter at the side of the road, tears down my face, and no idea how I got there. But hopefully these speakers are a very sunny trip in the country.

Thanks heaps to WrineX and sergiu2009 - you have inspired me to make something stupid that may not work!

Attachments

-

P1590342.jpg189.2 KB · Views: 199

P1590342.jpg189.2 KB · Views: 199 -

P1590341.jpg124 KB · Views: 166

P1590341.jpg124 KB · Views: 166 -

P1590336.jpg155 KB · Views: 153

P1590336.jpg155 KB · Views: 153 -

P1590330-2.jpg146 KB · Views: 143

P1590330-2.jpg146 KB · Views: 143 -

P1590329-2.jpg143 KB · Views: 204

P1590329-2.jpg143 KB · Views: 204 -

P1530060.jpg142.6 KB · Views: 283

P1530060.jpg142.6 KB · Views: 283 -

P1530058.jpg160.6 KB · Views: 171

P1530058.jpg160.6 KB · Views: 171 -

P1590345.jpg151.5 KB · Views: 184

P1590345.jpg151.5 KB · Views: 184 -

P1590344.jpg140.8 KB · Views: 174

P1590344.jpg140.8 KB · Views: 174 -

P1590325.jpg146.5 KB · Views: 151

P1590325.jpg146.5 KB · Views: 151

Last edited:

Hello,

There is too much resin and you membrane seem too heavy.

You should use a sucction pump, the carbon is a lot too wet.

And you should also experiment with high modulus vertical oriented fibers in order to reduce the weight and the holes in the diaphragm, there is a lot of weight to gain !

There is too much resin and you membrane seem too heavy.

You should use a sucction pump, the carbon is a lot too wet.

And you should also experiment with high modulus vertical oriented fibers in order to reduce the weight and the holes in the diaphragm, there is a lot of weight to gain !

hello silverprout.

do you mean too heavy with the new version? the new one is only 32g including the 2 copper wire voice coils, and the whole diaphragm is 1/2metre long....? the old version has 3 lobes and is like you say too wet - that was the very first trial.... do you really think there is too much resin in the first - second - third picture? 32 grams including voice coils i thought was good after a few other experiments with this thin tissue.... : (

the new one will only have one centre section only - no side wings - and made from the thin tissue in the first picture....

and yes to holes in the diaphragm also. thanks. i read about it this from sergiu looking through rubanoid patents i think.....

not sure what you mean by high modulus vertical oriented fibers - i have trouble finding carbon fibre tissue of any sort online or in australia - please let me know where i can find it and i will buy and give it a try, if not too expensive!!! the only thing i can find online is on specialty research with nanotube graphene strands and looks like it might be a million dollars for a square inch....

do you mean too heavy with the new version? the new one is only 32g including the 2 copper wire voice coils, and the whole diaphragm is 1/2metre long....? the old version has 3 lobes and is like you say too wet - that was the very first trial.... do you really think there is too much resin in the first - second - third picture? 32 grams including voice coils i thought was good after a few other experiments with this thin tissue.... : (

the new one will only have one centre section only - no side wings - and made from the thin tissue in the first picture....

and yes to holes in the diaphragm also. thanks. i read about it this from sergiu looking through rubanoid patents i think.....

not sure what you mean by high modulus vertical oriented fibers - i have trouble finding carbon fibre tissue of any sort online or in australia - please let me know where i can find it and i will buy and give it a try, if not too expensive!!! the only thing i can find online is on specialty research with nanotube graphene strands and looks like it might be a million dollars for a square inch....

Last edited:

i just found the weight of the old membrane with 3 sections like in the video - 220grams!!! hefty. : )

Last edited:

Run it in google translate if needed. 25USD per meter.

https://carbix.nordicshops.com/product.html/kolfiber-fleece-8g/m2?category_id=10

//

https://carbix.nordicshops.com/product.html/kolfiber-fleece-8g/m2?category_id=10

//

hello silverprout.

do you mean too heavy with the new version? the new one is only 32g including the 2 copper wire voice coils, and the whole diaphragm is 1/2metre long....? the old version has 3 lobes and is like you say too wet - that was the very first trial.... do you really think there is too much resin in the first - second - third picture? 32 grams including voice coils i thought was good after a few other experiments with this thin tissue.... : (

the new one will only have one centre section only - no side wings - and made from the thin tissue in the first picture....

and yes to holes in the diaphragm also. thanks. i read about it this from sergiu looking through rubanoid patents i think.....

not sure what you mean by high modulus vertical oriented fibers - i have trouble finding carbon fibre tissue of any sort online or in australia - please let me know where i can find it and i will buy and give it a try, if not too expensive!!! the only thing i can find online is on specialty research with nanotube graphene strands and looks like it might be a million dollars for a square inch....

You should care about the resin and the weight because of use of a "too stiff resin" should be limited to the strict minimum in order to minimise the weight and to have a margin for futher doping resins.

You perhaps use strutural resin that is not designed for audio (damping) the carbon cone loudspeaker manufacturers often use critically damped resins whith muliple layers.

Your transducer motor seems underpowered for a high mms, IMHO you should make some modelisation in order to fix your T&L parameters for a good alignement.

High quality carbon materials and resins are extremely expensive... you should use paper if you are not very rich.

cheers TNT and silverprout - that tissue is 8g , mine is 10g and random direction....

if this trial works i will have a look at modelling the motor - that is another world for me! there are 7 of N52 magnets 60x20x10mm between each of the side bars, and 8 of 50x25x10mm between the middle bar - i am not sure how to fit more magnets in this space and make the motor stronger. or do you mean make the coil stronger? it is 0.22mm copper wire, 9 turns 400mm long?

i do not know much about this, but i thought the only way to learn was to do, and try different things with the same magnet motor.... i enjoy working with my hands more than modelling on a computer, but i may have to yet. : ) in the end, all i want is to make something interesting that sounds good, that i learn a lot from, and expand my thinking. i am not after ultimate hifi. but i want very good. ha!!!

if this trial works i will have a look at modelling the motor - that is another world for me! there are 7 of N52 magnets 60x20x10mm between each of the side bars, and 8 of 50x25x10mm between the middle bar - i am not sure how to fit more magnets in this space and make the motor stronger. or do you mean make the coil stronger? it is 0.22mm copper wire, 9 turns 400mm long?

i do not know much about this, but i thought the only way to learn was to do, and try different things with the same magnet motor.... i enjoy working with my hands more than modelling on a computer, but i may have to yet. : ) in the end, all i want is to make something interesting that sounds good, that i learn a lot from, and expand my thinking. i am not after ultimate hifi. but i want very good. ha!!!

cheers TNT and silverprout - that tissue is 8g , mine is 10g and random direction....

if this trial works i will have a look at modelling the motor - that is another world for me! there are 7 of N52 magnets 60x20x10mm between each of the side bars, and 8 of 50x25x10mm between the middle bar - i am not sure how to fit more magnets in this space and make the motor stronger. or do you mean make the coil stronger? it is 0.22mm copper wire, 9 turns 400mm long?

i do not know much about this, but i thought the only way to learn was to do, and try different things with the same magnet motor.... i enjoy working with my hands more than modelling on a computer, but i may have to yet. : ) in the end, all i want is to make something interesting that sounds good, that i learn a lot from, and expand my thinking. i am not after ultimate hifi. but i want very good. ha!!!

I don't want to give you a headache... T&L parameters are relatively easy to measure and a simple rough alignment is very easy to do.

It is great experience and utterly funny to reinvent the wheel but it's better to make it approximately round 😉

https://en.wikipedia.org/wiki/Thiele/Small

i already have a headache. epoxy fumes. ha!

but to begin to take measurements, i need to make the new single section speaker working first. : ) when it is working, i will look at T/S measurement techniques, and like you say, find the best way to measure those easily. thanks.

i have made lots of normal speakers, mostly full range small mark audios lately - FAST speakers using small subs. and stupid folded bass horns or sonotubes and whatnot. but this is my first time to make actual speaker drivers, with that trial of three section rubanoid. it is fun. i am understanding so much more that sound is made from electromagnetic vibration of a membrane, and the subtleties that i cannot understand.

i see no point in making a round wheel of a speaker, when others can do it so much better than me. so like you say - it is utterly funny - but maybe this small reinvention also has some interesting sound characteristics for an amateur speaker dilletante to get his joys and kicks from. the final joys and kicks might come from thge design done as three of these each side as a kind of line source, crossed over around 200Hz to small integrated subs. maybe....

but to begin to take measurements, i need to make the new single section speaker working first. : ) when it is working, i will look at T/S measurement techniques, and like you say, find the best way to measure those easily. thanks.

i have made lots of normal speakers, mostly full range small mark audios lately - FAST speakers using small subs. and stupid folded bass horns or sonotubes and whatnot. but this is my first time to make actual speaker drivers, with that trial of three section rubanoid. it is fun. i am understanding so much more that sound is made from electromagnetic vibration of a membrane, and the subtleties that i cannot understand.

i see no point in making a round wheel of a speaker, when others can do it so much better than me. so like you say - it is utterly funny - but maybe this small reinvention also has some interesting sound characteristics for an amateur speaker dilletante to get his joys and kicks from. the final joys and kicks might come from thge design done as three of these each side as a kind of line source, crossed over around 200Hz to small integrated subs. maybe....

cheers TNT and silverprout - that tissue is 8g , mine is 10g and random direction....

if this trial works i will have a look at modelling the motor - that is another world for me! there are 7 of N52 magnets 60x20x10mm between each of the side bars, and 8 of 50x25x10mm between the middle bar - i am not sure how to fit more magnets in this space and make the motor stronger. or do you mean make the coil stronger? it is 0.22mm copper wire, 9 turns 400mm long?

i do not know much about this, but i thought the only way to learn was to do, and try different things with the same magnet motor.... i enjoy working with my hands more than modelling on a computer, but i may have to yet. : ) in the end, all i want is to make something interesting that sounds good, that i learn a lot from, and expand my thinking. i am not after ultimate hifi. but i want very good. ha!!!

Hi Orangealpaca,

I'm glad that we inspired others with what we achieved.

Congeats for your triple ruband and for this ideea.

Here are my thoughts about your single cilinder ruban:

- you have pretty strong magnets, why not use 4 or 3 mm gap (like mine) , this way you will gain flux and some extra juicy dB;

- your cilinders are a bit bumpy from the extra resin, can you sand paper them or make them somehow smoother?

- i have seen that you use hand winded coil wich i think it has a poor surface contact and i suggest a flexible printed pcb or diy cutted coil from thin backing Al foil like mine;

- the originall ruban has one coil and two cils wich elegantly dampens the peaks but yours have a cil and two coils wich i think it will shout at some peaks so i strongly recomend ading at least 5 diagonally folds allong the cil if you can( this is what i want to try also) with an almost sharp big wheel . See, this is why i use paper: its easyer and faster to make, cut, fold add laq etc;

- your diy dumping foam hinges that you want to atach to the membrane, i think it will restrain the sound abit so i suggest you should make another membrane and hook some thin elastics (two or more in parallel) and then compare them and tell us the results.

I just finished the assembly of the magnets and everything dryied completely including the primer that i sprayed on them. Now, it will gain almost double the flux compared to what i had so i'm working on my anti bending sistem for the plates..

Cheers

Sergiu

Ps: you are right about this speaker sounds very good. Lara Fabiani's live concerts sounds fantastically goood.

sergiu,

thanks heaps for your reply. its so fun to make sound from the ground up. i make these speakers because i am so bad at playing the piano and making REAL music.... and i want to make something different, from the ground up where i can, and learn as much as possible on the way.

- 3mm gap - that sounds good - first i need to try and make sure i can keep both the sides evenly in the 5mm gap. but if so, i will try this, it is easy enough to change my spacers while levering apart the magnet assemblies. i like juicy dB's.

- the bumps from the resin are due to ripples in polyethylene covering the mould for release - next time i will stretch it better and use much much thinner material. hopefully get rid of all the bumps and ripples.... learning carbon fibre from the start here.

- for the diagonal folds i do not understand, but will keep watching what you do and learn from that.

- i will get these ones working with the silicon rubber surrounds, if possible, and trial what you suggest if it looks like the surrounds are reducing the membrane movement - they are very soft and thin though - very flexible. but not sure how they are going to work in the whole driver setup yet.

anti-bending system - fun. magnetic force is an amazing thing. a separate non-magnet frame and tensioning the bars out towards that? will be interested to see what you do - sounds heavy....

thanks heaps for your reply. its so fun to make sound from the ground up. i make these speakers because i am so bad at playing the piano and making REAL music.... and i want to make something different, from the ground up where i can, and learn as much as possible on the way.

- 3mm gap - that sounds good - first i need to try and make sure i can keep both the sides evenly in the 5mm gap. but if so, i will try this, it is easy enough to change my spacers while levering apart the magnet assemblies. i like juicy dB's.

- the bumps from the resin are due to ripples in polyethylene covering the mould for release - next time i will stretch it better and use much much thinner material. hopefully get rid of all the bumps and ripples.... learning carbon fibre from the start here.

- for the diagonal folds i do not understand, but will keep watching what you do and learn from that.

- i will get these ones working with the silicon rubber surrounds, if possible, and trial what you suggest if it looks like the surrounds are reducing the membrane movement - they are very soft and thin though - very flexible. but not sure how they are going to work in the whole driver setup yet.

anti-bending system - fun. magnetic force is an amazing thing. a separate non-magnet frame and tensioning the bars out towards that? will be interested to see what you do - sounds heavy....

Hi orangealpaca,

Same as your case. I'm interested in very good quality reproduction and hi-fi because this is how i relax when i come home from work: leave the amp heat up when i eat then sit on a confortable sofa, drink a glass of diy wine and enjoy music with my wife.. 😎

I'm not an audiophille (i dont have 10000 hours of listening) but what i've heard till now at some of my friends houses was very good audio sistems (horns with some altecs , bandpass subs, by or try amping, ribons,+ some expensive 8.1 systems) and i can tell for shure that these strange speakers (rubans) are good competitors for what i've heard along with my friends so far and the realism and sound projection is just staggering.

Keep up the good work with the carbon fibre. I will post soon what i have in mind about the diagonall folds.

I cant wait to see your results with the silicon rubber.

"

anti-bending system - fun. magnetic force is an amazing thing. a separate non-magnet frame and tensioning the bars out towards that? will be interested to see what you do - sounds heavy...."

Something like that. But not that heavy. I found some pretty light materialls to play with. I will post this week about this.

Cheers

Sergiu

Same as your case. I'm interested in very good quality reproduction and hi-fi because this is how i relax when i come home from work: leave the amp heat up when i eat then sit on a confortable sofa, drink a glass of diy wine and enjoy music with my wife.. 😎

I'm not an audiophille (i dont have 10000 hours of listening) but what i've heard till now at some of my friends houses was very good audio sistems (horns with some altecs , bandpass subs, by or try amping, ribons,+ some expensive 8.1 systems) and i can tell for shure that these strange speakers (rubans) are good competitors for what i've heard along with my friends so far and the realism and sound projection is just staggering.

Keep up the good work with the carbon fibre. I will post soon what i have in mind about the diagonall folds.

I cant wait to see your results with the silicon rubber.

"

anti-bending system - fun. magnetic force is an amazing thing. a separate non-magnet frame and tensioning the bars out towards that? will be interested to see what you do - sounds heavy...."

Something like that. But not that heavy. I found some pretty light materialls to play with. I will post this week about this.

Cheers

Sergiu

Nice OrangeAlpaca, doing some work here! i will follow this topic thats for sure ! if i can help out let me know. i might have 2 flat copper coils somewhere depending on the size of yours you might be able to use them, i think they are around 28 cm

mine is 10g and random direction....

Can you provide a link for this please? I would be interested in this.

//

sergiu - that sounds like great relaxation. all the better with wine made yourself too! i have to agree with you about the sound of these weird speakers - or out of what i have heard from my crude experiments - i am hoping i can achieve something holographic, or maybe a mirage, or audio hallucination, with these speakers. or just a nice soundstage. : )

wrinex - thankyou so much for the generous offer of coils - can i wait until i have got better at carbon fibre and ask you? i want to make sure i can get it lighter, smoother and the whole process better. but i would love to try different coils after that. : )

tnt - this is the carbon fibre tissue - currently out of stock - i bought 6 sheets 1m x 0.5m, its very light - insanely so. i am sure if i got the wetting improved the weight could be lighter than i have....

https://hobbyking.com/en_us/carbon-fiber-tissue-fine-10g-m2-1mtr.html

i am waiting on a special glue for the silicone roll surround to the carbon fibre.... but then it is not far to trial if this basic idea works or not. the problem may be centreing the coils between the gap - i hope my carbon fibre cylinder is stiff and steady, because there is no adjustment possible yet, to change the width between the two coils running in the side-by-side magnet gaps.....

wrinex - thankyou so much for the generous offer of coils - can i wait until i have got better at carbon fibre and ask you? i want to make sure i can get it lighter, smoother and the whole process better. but i would love to try different coils after that. : )

tnt - this is the carbon fibre tissue - currently out of stock - i bought 6 sheets 1m x 0.5m, its very light - insanely so. i am sure if i got the wetting improved the weight could be lighter than i have....

https://hobbyking.com/en_us/carbon-fiber-tissue-fine-10g-m2-1mtr.html

i am waiting on a special glue for the silicone roll surround to the carbon fibre.... but then it is not far to trial if this basic idea works or not. the problem may be centreing the coils between the gap - i hope my carbon fibre cylinder is stiff and steady, because there is no adjustment possible yet, to change the width between the two coils running in the side-by-side magnet gaps.....

sergiu - that sounds like great relaxation. all the better with wine made yourself too! i have to agree with you about the sound of these weird speakers - or out of what i have heard from my crude experiments - i am hoping i can achieve something holographic, or maybe a mirage, or audio hallucination, with these speakers. or just a nice soundstage. : )

wrinex - thankyou so much for the generous offer of coils - can i wait until i have got better at carbon fibre and ask you? i want to make sure i can get it lighter, smoother and the whole process better. but i would love to try different coils after that. : )

tnt - this is the carbon fibre tissue - currently out of stock - i bought 6 sheets 1m x 0.5m, its very light - insanely so. i am sure if i got the wetting improved the weight could be lighter than i have....

https://hobbyking.com/en_us/carbon-fiber-tissue-fine-10g-m2-1mtr.html

i am waiting on a special glue for the silicone roll surround to the carbon fibre.... but then it is not far to trial if this basic idea works or not. the problem may be centreing the coils between the gap - i hope my carbon fibre cylinder is stiff and steady, because there is no adjustment possible yet, to change the width between the two coils running in the side-by-side magnet gaps.....

ofcourse you can wait 🙂 they wont run away 🙂

Try to use vacum and a bag if possible. Or if you have a alu-tube, lay the carbon and the resin on it and then, put shrink tube and heat it - that will press out all not needed resin. If it is a aluminum tube, put it in the freezer after it has hardened. After a while, you will get it off.

//

//

so i made the suspension and got the triple-magnet single cylinder rubanoid-like membranes to work. but they sounded pretty terrible.

there were peaks all over the place, and they were "veiled" in a way that was very disappointing. distortion. shouting peaks and silent valleys. i was supposed to measure them, but they sounded so awful it was pointless - unless they showed promise i was going to try the "standard" rubanoid design that everyone recommended and seems tried and true (ish...!!!)

i took off most of the rubber roll suspension, leaving little sections top and bottom - no improvement. i made a paper version, but it was not stable enough to stay true in the double magnet gap. i tried reinforcing it with some carbon fibre tissue and made it worse....

this design needs someone more patient, if there is any hope with it at all, likely because it is a silly idea from someone with no idea. the problem with making it work is the double gap - it means that the membrane has to be completely stiff and stable and stay in place. which is too limiting for materials. and too painful to make.

so i dropped it and tried a "standard" rubanoid....

wow - now that sounds better! i know, i know - you all told me not to reinvent the wheel, making some crazy new design that makes no sense, especially seeing as i know pretty much nothing about this sort of speaker. : )

and yes, yes - this is better - i am listening to the music and not the speaker!

so i made a paper version to compare, and made it orange, because that is the best colour and makes any speaker sound much better.

as a pair, they are very mismatched, one carbon fibre and one paper, but i can already hear some very interesting things in the music now - things i have not heard before. it makes me love the music more. this is what i want.

i am crossing over at 200hz and running some 6.5" bass below. at first listening there was some sibilance of female vocals, but that has diminished a lot. there is so much spoace and air. and i can hear the plucking of strings and the wood of the soundboard. it is especially good with simple acoustic instruments and vocals. it gets a little confused with complex music. plays electronic better than i thought. : ) they are changing the way they sound in a few days also - i guess they are brand new....

the carbon fibre is perhaps 6db louder (by my knobs) - i have not measured it though.... the paper sounds softer and warmer though.

so now i am decided - i will make four of these panels - two per side - using paper. this design is so much simpler to make, using two magnet bars and attached membrane sides, and with the simple securing system i have, i can adjust where the membrane sits in the gap.

its totally fun. yay for the normal rubanoid! i realise what you were all saying now. i am enjoying this very much!!!

thankyou again, especially to sergiu and wrine. you guys are inspiring with your perseverance and communicating your findings and thoughts.... i will post a proper thread when i have made all four panels and measured them.

there were peaks all over the place, and they were "veiled" in a way that was very disappointing. distortion. shouting peaks and silent valleys. i was supposed to measure them, but they sounded so awful it was pointless - unless they showed promise i was going to try the "standard" rubanoid design that everyone recommended and seems tried and true (ish...!!!)

i took off most of the rubber roll suspension, leaving little sections top and bottom - no improvement. i made a paper version, but it was not stable enough to stay true in the double magnet gap. i tried reinforcing it with some carbon fibre tissue and made it worse....

this design needs someone more patient, if there is any hope with it at all, likely because it is a silly idea from someone with no idea. the problem with making it work is the double gap - it means that the membrane has to be completely stiff and stable and stay in place. which is too limiting for materials. and too painful to make.

so i dropped it and tried a "standard" rubanoid....

wow - now that sounds better! i know, i know - you all told me not to reinvent the wheel, making some crazy new design that makes no sense, especially seeing as i know pretty much nothing about this sort of speaker. : )

and yes, yes - this is better - i am listening to the music and not the speaker!

so i made a paper version to compare, and made it orange, because that is the best colour and makes any speaker sound much better.

as a pair, they are very mismatched, one carbon fibre and one paper, but i can already hear some very interesting things in the music now - things i have not heard before. it makes me love the music more. this is what i want.

i am crossing over at 200hz and running some 6.5" bass below. at first listening there was some sibilance of female vocals, but that has diminished a lot. there is so much spoace and air. and i can hear the plucking of strings and the wood of the soundboard. it is especially good with simple acoustic instruments and vocals. it gets a little confused with complex music. plays electronic better than i thought. : ) they are changing the way they sound in a few days also - i guess they are brand new....

the carbon fibre is perhaps 6db louder (by my knobs) - i have not measured it though.... the paper sounds softer and warmer though.

so now i am decided - i will make four of these panels - two per side - using paper. this design is so much simpler to make, using two magnet bars and attached membrane sides, and with the simple securing system i have, i can adjust where the membrane sits in the gap.

its totally fun. yay for the normal rubanoid! i realise what you were all saying now. i am enjoying this very much!!!

thankyou again, especially to sergiu and wrine. you guys are inspiring with your perseverance and communicating your findings and thoughts.... i will post a proper thread when i have made all four panels and measured them.

Last edited:

Hi Orangealpaca,

I always thaught that the original simple ruban is a real contender for top end speakers... I imagined that the more complex 3cils ruban or single cil variant are more delicate to aproach. I am a laisy guy who likes to keep things simple, that's why i experimented with the classic aproach. 🙂

I told you, i told everyone here that with this speaker you hear real music and no speakers. You can really dive in and participate in the studio near the singer and hear him breathing , and i'm not joking here. 😎

Let me tell you how to make that confusiness from complex music vanish. It is very simple, and found it from mistake, after discussing with a friend from another forum wich made the coil exactly like you, on private : change the coil. Ask Wrine for a pair of printed coils or do them my way: directly cutt the coil on a cill then bond the cills together (it took me almost three weeks to proprely master the techinque, but hey not i can make coils how in want wethever i want in about an hour). And this solved the confusiness and the litle sibilance completely from the female vocals. I didnt wirewound the coils, but i asked him to try this because i didnt heard these effects on my flat coil version, and what do you know, the prob was indeed from the wirewounded coils.

I'm glad that you like them and i love the orange.

I tryied stacked cils at the same ruban frame and didn't see any benefit from doubling the number of membranes on the same ruban, maybe two different rubans stacked will improve the dispersion and dB's (because of the lowered inpedance) who knows. On my modifyied Super classe a Hiraga they had the same dB's but on the testing amp, jlh 1969 they sounded pretty loud. Cant wait to see your results.

Congrats again.

Cheers

Sergiu

I always thaught that the original simple ruban is a real contender for top end speakers... I imagined that the more complex 3cils ruban or single cil variant are more delicate to aproach. I am a laisy guy who likes to keep things simple, that's why i experimented with the classic aproach. 🙂

I told you, i told everyone here that with this speaker you hear real music and no speakers. You can really dive in and participate in the studio near the singer and hear him breathing , and i'm not joking here. 😎

Let me tell you how to make that confusiness from complex music vanish. It is very simple, and found it from mistake, after discussing with a friend from another forum wich made the coil exactly like you, on private : change the coil. Ask Wrine for a pair of printed coils or do them my way: directly cutt the coil on a cill then bond the cills together (it took me almost three weeks to proprely master the techinque, but hey not i can make coils how in want wethever i want in about an hour). And this solved the confusiness and the litle sibilance completely from the female vocals. I didnt wirewound the coils, but i asked him to try this because i didnt heard these effects on my flat coil version, and what do you know, the prob was indeed from the wirewounded coils.

I'm glad that you like them and i love the orange.

I tryied stacked cils at the same ruban frame and didn't see any benefit from doubling the number of membranes on the same ruban, maybe two different rubans stacked will improve the dispersion and dB's (because of the lowered inpedance) who knows. On my modifyied Super classe a Hiraga they had the same dB's but on the testing amp, jlh 1969 they sounded pretty loud. Cant wait to see your results.

Congrats again.

Cheers

Sergiu

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Planars & Exotics

- riffing off the rubanoid