Geary,

I presume that you reconed those drivers yourself. Where did you get the kits from?

No, just re-foamed the surrounds. Given the age of the paper cones, although in very good condition, I did give them a light coat of the glue diluted with water to about the consistency of skim milk. Went heavier at the surround area and the cone neck.

I have had good luck with Simply Speakers for recone kits and Orange County speakers for in-shop recone.

cheers,

Geary

if I space, I'd load and fire mine up with PYM1298 (much like Kappa 12a) - might get one running as its already in place -what's your new crossover look like? my tweeters need new diaphragms.

Simply Speakers or Crites are probably the best bets for good diaphragms.-what's your new crossover look like? my tweeters need new diaphragms.

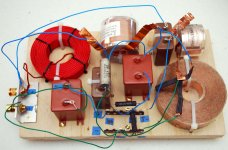

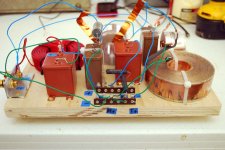

The crossovers are still a work in progress. Listen, rudimentary measurement, tweak. I am working out component values, size, layout. The current iteration sounds quite nice, and is a major improvement over the stock crossover with the caps replaced, even with minimal burn in, so maybe getting close. (The stock crossover is still in place, so it is a simple switching of wires to compare!)

I am trying to keep the crossover pretty simple, minimalist. Every time I try to get too complicated, I don't like the results. The finished crossover will take the place of the stock crossover enclosed under the mid horn.

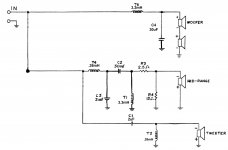

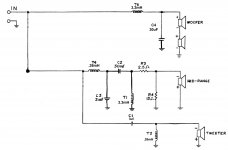

I think this schematic is pretty close to what I am listening to now.

Cheers,

Geary

Attachments

if I space, I'd load and fire mine up with PYM1298 (much like Kappa 12a) - might get one running as its already in place -

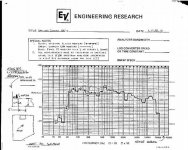

Here is an EV engineering frequency plot with three different woofers in the Sentry IVB:

Gefco, (Alnico)

EV ELM12

EV Force 12

Cheers,

Geary

Attachments

(i uploaded that a long time ago -info came from Jim Long) - those are MBGO(?) - is that bass inductor nicer sounding than say a steel-core ERSE?

I may have pinched the freq plot from you! The 30uF caps are MBGO, the 2uf caps are KBG, the 1uF are Good-All PIO. The bass coil is Solen. I don't know how it would compare to the iron core Erse. I am running such low power, (45 & 2A3 SET's), that saturation is an unlikely issue.

Cheers,

Geary

Cheers,

Geary

I think that I am close to where I want to be with the crossover. I moved the tweeter high pass back to 4750Hz with a 3uf cap. This improved the treble presence which was a bit lacking with the tweeter crossed over at the 6750 with a 2uF cap. This is the schematic of where I am today.

I am going to play around with the 1uf cap paralleled with the 2uF caps for the mid and treble. I will then bypass the mid 30uf cap with small value film or PIO cap. (Thinking .22 or .33 uf).

Cheers,

Geary

I am going to play around with the 1uf cap paralleled with the 2uF caps for the mid and treble. I will then bypass the mid 30uf cap with small value film or PIO cap. (Thinking .22 or .33 uf).

Cheers,

Geary

Attachments

Last edited:

Still Making Progress!!

I am really pleased with the music that the Sentry's effortlessly put forth! Still tweaking mid range bypass caps on the 30uf's.

Now to cosmetics...

The bass bins are 5/8" ply, not 3/4", so I am probably losing some mid/upper bass impact and resolution. I will need to do some sanding and heavy fill then...To make them more "furniturish" I plan to sheath them in 1/2" BB on the upper and lower sides and back. The BB will be stained a dark black cherry.

The "front" of the folded horn, (the flat 12.5" high front middle), and the same area on the sides will be solid 3/4" cherry forming a "beltline" of hardwood. Not only will this, hopefully, look nice, but in combination with the BB ply substantially decrease the cabinet resonance.

I have sanded down the mid horns and repainted them a 2 stage automotive cherry metallic. Just seems proper that 60/70'ish horns would be Cherry Red Metallic! 😱 There IS a REASON that EV splatter textured these horns. OMG there was no end to bumps, dropouts, pin holes and other blemishes from the molding process. Satin Black over heavy texture makes them disappear. Sanding the texture off, well....Every blemish I sanded and or filled made three more stand out proud!!

Here are some pics of the horns...

I am really pleased with the music that the Sentry's effortlessly put forth! Still tweaking mid range bypass caps on the 30uf's.

Now to cosmetics...

The bass bins are 5/8" ply, not 3/4", so I am probably losing some mid/upper bass impact and resolution. I will need to do some sanding and heavy fill then...To make them more "furniturish" I plan to sheath them in 1/2" BB on the upper and lower sides and back. The BB will be stained a dark black cherry.

The "front" of the folded horn, (the flat 12.5" high front middle), and the same area on the sides will be solid 3/4" cherry forming a "beltline" of hardwood. Not only will this, hopefully, look nice, but in combination with the BB ply substantially decrease the cabinet resonance.

I have sanded down the mid horns and repainted them a 2 stage automotive cherry metallic. Just seems proper that 60/70'ish horns would be Cherry Red Metallic! 😱 There IS a REASON that EV splatter textured these horns. OMG there was no end to bumps, dropouts, pin holes and other blemishes from the molding process. Satin Black over heavy texture makes them disappear. Sanding the texture off, well....Every blemish I sanded and or filled made three more stand out proud!!

Here are some pics of the horns...

Attachments

Last edited:

Stripped, Glues & Screwed!!

I have finished stripping the bass bins. Started with my belt sander. Not a chance. The EV finished gummed the belt almost instantly. Tried coarser belt, still not good. Had to drag out the 7" grinder and get sanding disks to fit. 80 grit and lots of changing disks, but worked. The factory coating was tough stuff!

I had to fill quite a few 1/4" and 3/8" holes in the sides. Must have been used to mount something(s)!? Dowels and glue, good to go!

The entire bass bin was stapled, mostly held up well except for the seems at the corners, (well all of the abuse occurs!). I glued and screwed the entire perimeter. I still need to fill the the countersinks holes and a few gouges and then sand again. Nice improvement in the "knuckle knock" test. Everything is and sounds solid. I will pick up the BB ply and cherry stock and start prepping to convert from beasts to beauties!

I air blasted the sanding dust and blew out the folded horns. I cannot believe the amount of crap that came flying out of the bins. Hell, that's got to improve the bass just having clean soundways!!!

Cheers,

Geary

I have finished stripping the bass bins. Started with my belt sander. Not a chance. The EV finished gummed the belt almost instantly. Tried coarser belt, still not good. Had to drag out the 7" grinder and get sanding disks to fit. 80 grit and lots of changing disks, but worked. The factory coating was tough stuff!

I had to fill quite a few 1/4" and 3/8" holes in the sides. Must have been used to mount something(s)!? Dowels and glue, good to go!

The entire bass bin was stapled, mostly held up well except for the seems at the corners, (well all of the abuse occurs!). I glued and screwed the entire perimeter. I still need to fill the the countersinks holes and a few gouges and then sand again. Nice improvement in the "knuckle knock" test. Everything is and sounds solid. I will pick up the BB ply and cherry stock and start prepping to convert from beasts to beauties!

I air blasted the sanding dust and blew out the folded horns. I cannot believe the amount of crap that came flying out of the bins. Hell, that's got to improve the bass just having clean soundways!!!

Cheers,

Geary

Attachments

Well ...

I got my 4 Gefco drivers back from Orange County Speakers yesterday. They did a really nice job of cleaning them up and reconing them. The recone job cost me $460 after shipping. Now if only the temps in Bakersfield would drop down to human tolerable levels I would install them back my refurbed cabinets.

I got my 4 Gefco drivers back from Orange County Speakers yesterday. They did a really nice job of cleaning them up and reconing them. The recone job cost me $460 after shipping. Now if only the temps in Bakersfield would drop down to human tolerable levels I would install them back my refurbed cabinets.

5 days in a row of 100 degrees plus here in the East Bay. We always have a few days of high heat, but usually not until late August - September. Just not motivated to do much in that heat. I grew up in the north valley, so hot summers were the norm, but nothing like the past couple of years.

Glad to here that the Gefco's turned out well. They really do sound quite nice, to me. Will be most interested in your thoughts! Did you have them re--magnetize?

Cheers,

Geary

Glad to here that the Gefco's turned out well. They really do sound quite nice, to me. Will be most interested in your thoughts! Did you have them re--magnetize?

Cheers,

Geary

"Did you have them re--magnetized?"

Nope. They assured me that they didn't need it.

It's been between 100 and 110 degrees in Bakersfield for the last few weeks with no relief in sight. Geez ...

Nope. They assured me that they didn't need it.

It's been between 100 and 110 degrees in Bakersfield for the last few weeks with no relief in sight. Geez ...

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Restoring Electro-Voice Sentry IV-A