Although made on different test set ups it looks to prove a point. It shouldn't take much to get the TD124 rumble to my estimate.

I recently made a new power supply for the cheaper Garrard 601. That was at the same time as the passive PSU I show in this thread. The passive PSU should help. 2218/9

I recently made a new power supply for the cheaper Garrard 601. That was at the same time as the passive PSU I show in this thread. The passive PSU should help. 2218/9

Last edited:

Although made on different test set ups it looks to prove a point. It shouldn't take much to get the TD124 rumble to my estimate.

I recently made a new power supply for the cheaper Garrard 601. That was at the same time as the passive PSU I show in this thread. The passive PSU should help. 2218/9

If you still consider that this measurement is done without new bearing , E50 motor, and powersupply !

I have done vibration measurements on the E50 motor with and without my own CPS powersupply and also with a XR2206 oscillator supply.I think these are the first measurements ever done in such a setup imho. Will post them later on.

I question if anything is wrong with most of the Thorens parts. The 501 started life as a 401 more or less. We were surprised how good the majority of the parts were. It's very small things that matter.

Garrard for some reason made sure the motors worked on 40 Hz for a small part of the UK that had 40 Hz ( perhaps the boss of ICI wanted a 301, it was said to be an ICI housing estate ). I suspect it was a small but important difference. The Garrard motor looks almost identical to the TD124, no great surprise. I took the idea that the Garrard was more typically a hysterisis hybrid from technical reviews of the day. I did Squirel cage at college so should have questioned it. The 40 to 60 Hz range is very useful for 78 transcription if using a 50 Hz set up.

Garrard for some reason made sure the motors worked on 40 Hz for a small part of the UK that had 40 Hz ( perhaps the boss of ICI wanted a 301, it was said to be an ICI housing estate ). I suspect it was a small but important difference. The Garrard motor looks almost identical to the TD124, no great surprise. I took the idea that the Garrard was more typically a hysterisis hybrid from technical reviews of the day. I did Squirel cage at college so should have questioned it. The 40 to 60 Hz range is very useful for 78 transcription if using a 50 Hz set up.

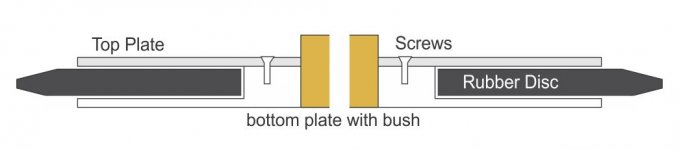

what are the advantages of full metal 'O' ring idler ? Wouldn't a quality circular rubber sheet pressed between two circular metal plates damp vibrations ? Like precision made gasket type (4/5 mm thick and tapered at outer edge) rubber wheel sandwiched between metal plate. This way we can replace worn out idlers etc.

Regards.

Regards.

I question if anything is wrong with most of the Thorens parts. The 501 started life as a 401 more or less. We were surprised how good the majority of the parts were. It's very small things that matter.

Garrard for some reason made sure the motors worked on 40 Hz for a small part of the UK that had 40 Hz ( perhaps the boss of ICI wanted a 301, it was said to be an ICI housing estate ). I suspect it was a small but important difference. The Garrard motor looks almost identical to the TD124, no great surprise. I took the idea that the Garrard was more typically a hysterisis hybrid from technical reviews of the day. I did Squirel cage at college so should have questioned it. The 40 to 60 Hz range is very useful for 78 transcription if using a 50 Hz set up.

No special motor needed for 40Hz, just a larger stepped pulley.

I brought a 50Hz deck from the UK to 60Hz Canada and I just made a smaller stepped pulley.

The base price of 10,500 quid for a idler wheel deck is a little rich, I'm thinking?

That's interesting. I'd expect the rhythmic noise to be synchronous to the rotation of the step pulley, which is virtually unchanged regardless of what speed is selected, if the step pulley is the culprit, rather than being synchronous to the rotation of the idler, which changes in frequency depending upon which speed is selected.

I suppose a bad bushing in the step pulley could make a noise sympathetic to a problem with the idler, in which case I'd want to address both the idler and the step pulley.

I have seen this issue and one of my TD 124's

I replace the bearing in the stepped pulley. Solved the problem.

I also flipped over the shaft the pulley rides on, to use the new surface.

That solved my issue for me.

Bob

Not quite true if testing torque. Mostly true if voltage factored in. The cost of high end stuff is so few made. Thorens had to make 20 000 units before the investment was returned. A 401 is very nearly as good.No special motor needed for 40Hz, just a larger stepped pulley.

I brought a 50Hz deck from the UK to 60Hz Canada and I just made a smaller stepped pulley.

The base price of 10,500 quid for a idler wheel deck is a little rich, I'm thinking?

Not quite true if testing torque. Mostly true if voltage factored in. The cost of high end stuff is so few made. Thorens had to make 20 000 units before the investment was returned. A 401 is very nearly as good.

We are now in the age of CNC machining, there is no excuse for exorbitant prices.

I request to see a video of the second idler wheel running against the stepped pulley. If the other wheel runs true, the problem is isolated to one bad wheel. If the other wheel exhibits the same behavior as the first, the problem is not isolated.

Steve,

As mentioned in an earlier post it appears that improper seating of the o-ring in the idler exerted enough force on the idler to displace it slightly. Once the o-ring was properly seated the idler stopped wobbling and the noise became almost indiscernible with the stethoscope. The table has been reassembled and I hope to do some listening tests this weekend.

That would be an impractical and overly complex way to accomplish what is already a simple arrangement

Squeezing a rubber sheet would more than likely create the circumference to be out of round and need grinding to spec and would it stay that way over time?

You would create two different tensions on the rubber , under the plates and what exits and touches the platter.

The O ring is stretched and would stay in one mode for its life span. it should be super glued to its pulley IMO

The pulley is too small in size to have any internal self resonance that is already damped by the O ring

The idler turns at a relatively slow speed and all that TT needs from it, is to be perfectly round and with no bearing issues

Regards

David

Squeezing a rubber sheet would more than likely create the circumference to be out of round and need grinding to spec and would it stay that way over time?

You would create two different tensions on the rubber , under the plates and what exits and touches the platter.

The O ring is stretched and would stay in one mode for its life span. it should be super glued to its pulley IMO

The pulley is too small in size to have any internal self resonance that is already damped by the O ring

The idler turns at a relatively slow speed and all that TT needs from it, is to be perfectly round and with no bearing issues

Regards

David

I need to order some bronze bearings for a td124 60,000 ish serial number. I can't seem to find the 5id, 8od 12 long bronze bushings for the idler pulley. I did get the 4x7x6 step pulley. If I have to order from U.K. Does anyone have the dimensions on the other bronze bearings or washers like the main shaft? Any others? My table arrives Friday so

That would be an impractical and overly complex way to accomplish what is already a simple arrangement

Squeezing a rubber sheet would more than likely create the circumference to be out of round and need grinding to spec and would it stay that way over time?

You would create two different tensions on the rubber , under the plates and what exits and touches the platter.

The O ring is stretched and would stay in one mode for its life span. it should be super glued to its pulley IMO

The pulley is too small in size to have any internal self resonance that is already damped by the O ring

The idler turns at a relatively slow speed and all that TT needs from it, is to be perfectly round and with no bearing issues

Regards

David

I agree on complexity. I am not an expert on anything But if one wants to DIY it could be an alternative; if new idlers are expensive. Only light pressure should also work so as to not to squeeze rubber too hard. A C Clip can be used instead of screws. Or superglued (or any other glue) on side surface. Metal plates can be replaced by Acrylic. Rubber edge can be ground after fitting. Basically I am thinking of on avoiding molding rubber, easy replacement of worn out rubber, affordable DIY aspects of it.

Regards.

Reporting back here on my idler issue.

My original idler was worn and was not moving in a concentric manner.

The replacement idler from Audio Silente appeared to be doing the same. I learned that while the o-ring might eventually seat itself properly, it doesn't necessarily lay in the groove as it should when initially installed for proper concentric movement. This is particularly true of the red silicone o-ring because of it's tackiness.

To seat the o-ring properly I first pulled the o-ring slightly out of it's groove and released, moving around the entire circumference of the o-ring several times. Inspection of the o-ring with the usb microscope revealed improvement. Then I ran the motor with the idler on the 33 step while applying slight pressure with my hand to the idler cage toward the step pulley. This seated the o-ring further and caused it to move in a nearly perfect concentric manner. Once the o-ring was properly seated, the aluminum inner portion of the idler ran concentrically around the spindle.

This new idler sounds great. It's hard to quantify the improvement, but perhaps the music is presented with a greater sense of urgency. More dynamic maybe

I can only say with certainty that it sounds very good.

My original idler was worn and was not moving in a concentric manner.

The replacement idler from Audio Silente appeared to be doing the same. I learned that while the o-ring might eventually seat itself properly, it doesn't necessarily lay in the groove as it should when initially installed for proper concentric movement. This is particularly true of the red silicone o-ring because of it's tackiness.

To seat the o-ring properly I first pulled the o-ring slightly out of it's groove and released, moving around the entire circumference of the o-ring several times. Inspection of the o-ring with the usb microscope revealed improvement. Then I ran the motor with the idler on the 33 step while applying slight pressure with my hand to the idler cage toward the step pulley. This seated the o-ring further and caused it to move in a nearly perfect concentric manner. Once the o-ring was properly seated, the aluminum inner portion of the idler ran concentrically around the spindle.

This new idler sounds great. It's hard to quantify the improvement, but perhaps the music is presented with a greater sense of urgency. More dynamic maybe

I can only say with certainty that it sounds very good.

Hi terrya,

Congrats on your troubleshooting success. I was following your posts, and I share the same sentiment that the idler condition and quality makes a big difference with all else being equal. FWIW, I have Mirko's replacement idler wheel..

Congrats on your troubleshooting success. I was following your posts, and I share the same sentiment that the idler condition and quality makes a big difference with all else being equal. FWIW, I have Mirko's replacement idler wheel..

Hi to all,

Does anyone know where I can pick up a clutch assembly for my TD124-II? The previous owner decided it was superfluous and removed it. I have been hunting around but can't seem to source it. Push comes to shove I'll have to have one manufactured.

Kevin

Does anyone know where I can pick up a clutch assembly for my TD124-II? The previous owner decided it was superfluous and removed it. I have been hunting around but can't seem to source it. Push comes to shove I'll have to have one manufactured.

Kevin

Getting dimensions for all the bushings, bearings would be great as well.

bronzebushings.com

found the bearings I needed there

- Home

- Source & Line

- Analogue Source

- Restoring and Improving A Thorens TD-124 MKII