It may be suggestive, but on occasion it still feels as a dent on top of my way.

(cost/benefit has never been my forte)

(cost/benefit has never been my forte)

The fresh solder effect is real. But not for the fresh solder! When you resolder all the joints on a board you also fill in the through plated holes. As I suspect you know when the through plated connection needs to be really low loss you use a matrix of them. (Or at least some folks do.)

There is a slight but measurable drop in resistance when the holes are filled. So in some circuits there really is a performance change. Did show this in an article years back. Distortion really did drop with filled holes. Of course the wise will not use a through plated hole for the lower end of the voltage feedback divider.

Of course on hand soldered boards done originally with a lack of skill and a poor quality flux resoldering may actually help.

I believe the reference to new solder was more specific than soldering vias…..

Things have improved over the years including via plating…. I do know when I started out gassing, barrel cracks, limited plating, hole contamination where all problems, the trouble was allowing the vias to be filled with solder during wave soldering could cause solder balls and other undesirable problems on the top surface of the board. Generally these problems are no longer a concern for most electronics...

Today’s SMD boards are very rarely wave soldered so via's are not filled (or are filled at board fabrication stage with an epoxy, conductive or not conductive). Todays via's are usually a 0.3mm finished hole size (and smaller) with plating from 0.025 to greater than 0.050 plating in the barrel (depends what you specify). I do wonder how much difference it would make today (filling the via with solder), not much I expect and generally going through vias is not considered too much of a problem…and it is only on the really sensitive stuff where I have seen restrictions on vias, that said I do like to see feedback loops and other critical analogue nets routed on one side of a PCB where possible… In fact most analogue especially round op-amps can be done single sided with careful placement.

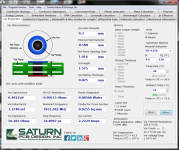

The attached show the parasitic’s of adding a standard via with 0.025 and 0.035mm plating in the barrel.

And a bit on solder joint resistance…. There are tons of white papers and research documentation covering all aspects of this including filled vias, also the problem of filling vias and via cracking due to different expansion rates between the metal filling the via and the rest of the PCB.

https://www.smtnet.com/library/files/upload/solderjointproperties.pdf

forgot this link...

http://www.pcbuniverse.com/pcbu-tech-tips.php?a=5

Attachments

Last edited:

That's good enough for me!

me too..we use life time to improve your system to ear a nuance in the music...

no diy no party...try to improve your system for 10year and you will noted when chance a screw

Last edited:

me too..we use life time to improve your system to ear a nuance in the music...

no diy no party...try to improve your system for 10year and you will noted when chance a screw

Of course - verything sounds different with a screw in your ear! 😉

no diy no party...try to improve your system for 10year and you will noted when chance a screw

No I won't. I've been doing DIY on and off for over 25 years.

Of course - verything sounds different with a screw in your ear! 😉

I think I am chanelling Jacco today as I completely misread that at first. Having a day bed in the living room does that to the mind...

Well Marce I think we agree. Resoldering perfectly good joints will only make a difference on a well made board if you screw up some of them. Then there will be a difference just not an improvement.

Some folks probably did get an improvement from filling vias. I do remember when standard service practice for mysterious ailments was to resolder any through plated holes that did not have leads going through them. Fixed many a problem child. There actually were products manufactured for audio where they hand soldered both sides of the boards.

So as usual some legends (fairy tales) do start with a basis in fact.

Another useful soldering tip for the newbie... Hold the soldering iron by the cold end!

Some folks probably did get an improvement from filling vias. I do remember when standard service practice for mysterious ailments was to resolder any through plated holes that did not have leads going through them. Fixed many a problem child. There actually were products manufactured for audio where they hand soldered both sides of the boards.

So as usual some legends (fairy tales) do start with a basis in fact.

Another useful soldering tip for the newbie... Hold the soldering iron by the cold end!

Jan 😛 only with copper one...like Pioneer use in the past ,M90 well build but sound horrible... 1986 seems like yesterday

Last edited:

Hi Ed, not sure that I fully agree...... Resoldering perfectly good joints will only make a difference on a well made board if you screw up some of them. Then there will be a difference just not an improvement.

I have done hundreds of output stage blanket resolders over the decades.

One interesting effect I have consistently noted is amplifiers sounding 'wrong' initially at low to mid levels and this behavior continues regardless of power cycling.

Gradually increasing volume produces an interesting effect....the 'wrongness' gets worse until clip events, when the sound suddenly cleans and 'relaxes'.

This is a once off event, and won't usually be noticed unless listening for it.

Not sure of the mechanism, maybe soldering heat demagnetises component leads which then get remagnetised by clipping event high peak currents...or something...dunno.

Dan.

Not sure of the mechanism, maybe soldering heat demagnetises component leads which then get remagnetised by clipping event high peak currents...or something...dunno.

Dan.

Except the Currie point for most lead materials would be >1000 F

Hi Ed, not sure that I fully agree.

I have done hundreds of output stage blanket resolders over the decades.

One interesting effect I have consistently noted is amplifiers sounding 'wrong' initially at low to mid levels and this behavior continues regardless of power cycling.

Gradually increasing volume produces an interesting effect....the 'wrongness' gets worse until clip events, when the sound suddenly cleans and 'relaxes'.

This is a once off event, and won't usually be noticed unless listening for it.

Not sure of the mechanism, maybe soldering heat demagnetises component leads which then get remagnetised by clipping event high peak currents...or something...dunno.

Dan.

More likely an oxide or similar is cleared by the full scale signal that occurs throughout most of the circuitry when you clip. Scott doesn't believe in the mechanism, but it is why folks tap on a dead microphone, sometimes that does bring them back to life.

Of course I just came back from a church where the complaint was the volume jumped up and then down by a lot during a service. I just had to clean one contact to fix the problem. (Luck was in finding it!)

Scott doesn't believe in the mechanism, but it is why folks tap on a dead microphone, sometimes that does bring them back to life.

Wow, talk about full circle I was the one that said all you are doing is rubbing the contacts mechanically to clean off gunk. It is is either contact or no contact there are no mV level "jumps' across gaps or <mV wide flat zones in signals. I wish you would go back and see some of the comments/pics posted.

Tapping on the mic mechanically remakes the electrical connection, nothing more.

Last edited:

Wow, talk about full circle I was the one that said all you are doing is rubbing the contacts mechanically to clean off gunk. It is is either contact or no contact there are no mV level "jumps' across gaps or <mV wide flat zones in signals. I wish you would go back and see some of the comments/pics posted.

Tapping on the mic mechanically remakes the electrical connection, nothing more.

Gotcha! In a standard light switch the voltage is high enough to clear the contacts. For low level use there are the gold bifurcated crossbar contacts used in relays and switches to ensure both wiping, redundancy, high contact pressure and a surface that does not oxidize. Then there are the in between contacts/connections that can clear at 25 or so volts. The amplifiers are most likely case 3.

Then there are the in between contacts/connections that can clear at 25 or so volts. The amplifiers are most likely case 3.

I don't have any 25V level mics, as for the 25V please provide a demonstration that requires no mechanical action at all. Also how would an amplifier with non-connections not be broken to an obvious level?

I don't have any 25V level mics, as for the 25V please provide a demonstration that requires no mechanical action at all. Also how would an amplifier with non-connections not be broken to an obvious level?

When you whack a mic you can get several volts. I know you don't think that should work but many have experience it does.

When the amp clips you can have close to the rail voltage in places that normally do not. So it could be anything from a current source, mirror, to alternate return path say through a resistor across another component.

Why do you think cold solder joints are intermittent? Mechanical motion is certainly one issue, perhaps even EMF.

Why would the volume in a sound system in a church change volume in the middle of a service? Sound system has no operator controls and is locked up and out of the way. Massive stone church perhaps even less than .05G vibration. 🙂

When you whack a mic you can get several volts. I know you don't think that should work but many have experience it does.

When you whack a mic you disturb the mechanical connections, no evidence has been provided that anything more fixes the problem. Loose connections go bad through oxidation, in house wiring usually to eventual complete failure including catastrophic. There is an enormous data base of fire safety forensics to back this up. They are not repaired by intermittent 125V application.

- Status

- Not open for further replies.

- Home

- Member Areas

- The Lounge

- Resistor Sound Quality?