I'm repairing some Proac speakers with their basic 'Black Ash' finish.

The veneer had lots of scratches so I tried using scratch repair wax (crayons) and using a black wax polish but they didn't really help much.

So I just wet sanded with 600 grit back to the white wood under the finish and succeeded in getting all the scratches out. After allowing time for the wood to dry I dry sanded with 1000 grit and then rubbed in Nitrostain black wood dye. I've put on a few coats but it's no where near as black and opaque a finish as the original. Some areas of the wood haven't taken the stain so well and generally it looks dark brown rather than black. Basically it's been a failure!.

I can tell the original finish was sprayed on because of the overspray on the inside of the cabinet, but does anyone have any idea what they sprayed on? It has to be a completely opaque black with a medium glossy finish, but also the coating needs to be thin so it doesn't obscure the texture of the woods grain.

I'm thinking maybe they stained black and then put on a coat of thinned down very black varnish. I'd really like to get the panel I sanded looking like the rest of the speaker again although if I can reproduce the finish I'll probably the

BB

The veneer had lots of scratches so I tried using scratch repair wax (crayons) and using a black wax polish but they didn't really help much.

So I just wet sanded with 600 grit back to the white wood under the finish and succeeded in getting all the scratches out. After allowing time for the wood to dry I dry sanded with 1000 grit and then rubbed in Nitrostain black wood dye. I've put on a few coats but it's no where near as black and opaque a finish as the original. Some areas of the wood haven't taken the stain so well and generally it looks dark brown rather than black. Basically it's been a failure!.

I can tell the original finish was sprayed on because of the overspray on the inside of the cabinet, but does anyone have any idea what they sprayed on? It has to be a completely opaque black with a medium glossy finish, but also the coating needs to be thin so it doesn't obscure the texture of the woods grain.

I'm thinking maybe they stained black and then put on a coat of thinned down very black varnish. I'd really like to get the panel I sanded looking like the rest of the speaker again although if I can reproduce the finish I'll probably the

BB

I would try wood wax with graphite powder as pigment, but I am not sure this will overlay the brown. The only pigment that is REALLY black is active coal (artists call it bone black). This will definitely overlay the brown, but without the glossy look.

Stop crying. Post a picture of the screwed up area.

Chances are, on the factory, the speakers are sprayed with pigmented lacquer (nitrocellulose or pre cut nitro)and not stained at all. You could get same thing in a spray can and reproduce the finish. Stain is too translucent and will never give you that opacity black color.

Chances are, on the factory, the speakers are sprayed with pigmented lacquer (nitrocellulose or pre cut nitro)and not stained at all. You could get same thing in a spray can and reproduce the finish. Stain is too translucent and will never give you that opacity black color.

BarakaBloke said:

I'm thinking maybe they stained black and then put on a coat of thinned down very black varnish. I'd really like to get the panel I sanded looking like the rest of the speaker again although if I can reproduce the finish I'll probably the

BB

Hi,

First, you sanded too fine. When you sand raw wood (or veneer) with very fine sandpaper, it "burnishes" the wood, making it harder to stain. 120 - 220 grit with the grain would have been good for this finish.

For stain, use thinned alkyd based paint. Yes, I said paint, not stain. You thin this with mineral spirits (Varsol). You can paint this on and let it dry. DO NOT wipe it off. It can be sprayed, and this would give the best results, but if you're careful it can be done very well with a good quality brush.

More coats will make it darker until you have the right colour. You can then clear coat this with satin polyurethane.

MJL is DEAD ON the money here.

Many ash finishes are done with "paints" that fill the pores rather than "stains".

I have done striking finishes by: sanding the wood smooth (no more than 220 -320) and PAINTING the wood black, then sanding to re-expose the pores while leaving the pores blackened.

🙂

Many ash finishes are done with "paints" that fill the pores rather than "stains".

I have done striking finishes by: sanding the wood smooth (no more than 220 -320) and PAINTING the wood black, then sanding to re-expose the pores while leaving the pores blackened.

🙂

Maybe far too specific here, but I just googled out that iron oxide black is either brownisch (your stain) or blueish (stain common in Germany).

Thanks folks. Hopefully these pictures will convey what I was trying to

describe.

These are shots of good areas of the original finish which I want recreate on

the face I sanded.

It's hard to photograph black but I think it gives the idea.

How can I recreate this finish on the face I sanded?

describe.

These are shots of good areas of the original finish which I want recreate on

the face I sanded.

It's hard to photograph black but I think it gives the idea.

How can I recreate this finish on the face I sanded?

Attachments

I'm inclined to agree with R-Carpenter, likely the finish was simply painted on; that is it was 'paint' not stain.

It's difficult to experiment on the actual cabinet itself. I would be better if you had a spare piece of wood. I think the first thing you need to determine is the degree of flatness of the finish; flat, satin, semi-gloss, or gloss. I'm thinking likely satin or semi-gloss. Then see if you can duplicate that.

It is possible to paint with flat black, then coat with clear satin or semi-gloss. Or any other combination to achieve the desire result, like paint it with gloss black then finish it with satin clear.

At any rate, it's a complex process trying to match an existing finish. It would be better to simply put a new finish on the whole thing. Lightly sand, choose your undercoat and spray, then choose your finish coat and spray.

Are you familiar with Candy paints. They are the clear colored paints they put over metal-flake on custom motorcylces. You could spray an undercoat of flat or satin black, then sand it lightly, and coat it with a clear gloss or satin black 'Candy'. That would give the appearance of a very deep finish.

Not worth much. Just a few thoughts.

steve/bluewizard

It's difficult to experiment on the actual cabinet itself. I would be better if you had a spare piece of wood. I think the first thing you need to determine is the degree of flatness of the finish; flat, satin, semi-gloss, or gloss. I'm thinking likely satin or semi-gloss. Then see if you can duplicate that.

It is possible to paint with flat black, then coat with clear satin or semi-gloss. Or any other combination to achieve the desire result, like paint it with gloss black then finish it with satin clear.

At any rate, it's a complex process trying to match an existing finish. It would be better to simply put a new finish on the whole thing. Lightly sand, choose your undercoat and spray, then choose your finish coat and spray.

Are you familiar with Candy paints. They are the clear colored paints they put over metal-flake on custom motorcylces. You could spray an undercoat of flat or satin black, then sand it lightly, and coat it with a clear gloss or satin black 'Candy'. That would give the appearance of a very deep finish.

Not worth much. Just a few thoughts.

steve/bluewizard

Think of it this way. 99% of commercial speakers are sprayed in the spray booth. 99% of them use pre catalyzed or regular nitrocellulose lacquer. From the picture, it’s obvious that these cabinets are spray-painted. So, just do the same thing.

Where to find it:

Look in the phone book at “furniture restoration supplies”, “finishing supplies” Call them and ask them if they carry Satin Black nitrocellulose in the form of spray can. In US, it’s about $7 a can.

How to spray:

Nitro stinks; so either do it outdoors or with the fan in the window. It’s also flammable, so no smoking.

Lay your speaker on the side and give it a couple of thin crosshatch coats. If you get a hang of it, you could give a entire cabinet a quick overall. One can should be more then enough.

If you concern about abuse, get a can of clear satin lacquer also and topcoat with it.

🙂

Where to find it:

Look in the phone book at “furniture restoration supplies”, “finishing supplies” Call them and ask them if they carry Satin Black nitrocellulose in the form of spray can. In US, it’s about $7 a can.

How to spray:

Nitro stinks; so either do it outdoors or with the fan in the window. It’s also flammable, so no smoking.

Lay your speaker on the side and give it a couple of thin crosshatch coats. If you get a hang of it, you could give a entire cabinet a quick overall. One can should be more then enough.

If you concern about abuse, get a can of clear satin lacquer also and topcoat with it.

🙂

Attachments

Hi,

I'll bet the ProAc rep can get you a spray can of the "Paint." It is better than having to re-do both boxes to get them to match because the brand of paint and clear coat are a different manufacturer and just aren't right on color wise and texture or sheen wise. Maybe with the exact product you can feather it and make it look like new, like a car at the body shop! I know that Roman does this all day long for a living so I am sure he can give you better advice than me. It sounds like all the guys are telling you the same thing. The only thing I can add is where to get the original product. Maybe anyway!

His name is Richard. You can email him: Modaudio@aol.com

He has always been real helpful with me!

Good luck! I have to hear about people with ProAc problems!

Regards//Keith

I'll bet the ProAc rep can get you a spray can of the "Paint." It is better than having to re-do both boxes to get them to match because the brand of paint and clear coat are a different manufacturer and just aren't right on color wise and texture or sheen wise. Maybe with the exact product you can feather it and make it look like new, like a car at the body shop! I know that Roman does this all day long for a living so I am sure he can give you better advice than me. It sounds like all the guys are telling you the same thing. The only thing I can add is where to get the original product. Maybe anyway!

His name is Richard. You can email him: Modaudio@aol.com

He has always been real helpful with me!

Good luck! I have to hear about people with ProAc problems!

Regards//Keith

Thanks for all the brilliant advice folks 🙂

I'll try ProAc for the proper paint. If they can't help or want silly money I

can resort to car spares/repairs type shops near me who stock loads

of cellulose type aerosol paints.

I still have problem though: I didn't realise sanding would reduce the

amount of the large open pores (or whatever they're called) in the

wood surface. Without them the painted surface won't have the wood

grain texture you can see in my photos. Is there a trick for reopening

the woods pores ? The only idea I've had is wire brushing followed by

a light sand, but that's a total guess!

BB

I'll try ProAc for the proper paint. If they can't help or want silly money I

can resort to car spares/repairs type shops near me who stock loads

of cellulose type aerosol paints.

I still have problem though: I didn't realise sanding would reduce the

amount of the large open pores (or whatever they're called) in the

wood surface. Without them the painted surface won't have the wood

grain texture you can see in my photos. Is there a trick for reopening

the woods pores ? The only idea I've had is wire brushing followed by

a light sand, but that's a total guess!

BB

That veneer originally might have been treated with a chemical to open the grain more than normal. The wire brush could scratch the summer growth (hard, flat parts), and make a real mess of it.

I would sand the entire side with 120 grit paper. Then 220 grit. Clean with a vacuum or blower, brushing out the grain with a toothbrush.

Then paint it and see how it looks. Worse comes to worst, you completely refinish both boxes on all sides.

I would sand the entire side with 120 grit paper. Then 220 grit. Clean with a vacuum or blower, brushing out the grain with a toothbrush.

Then paint it and see how it looks. Worse comes to worst, you completely refinish both boxes on all sides.

Ash as any other wood has pores through out the thickness, solid or veneer, doesn’t matter. You didn’t sand off the pores, you just made the surface so smooth that you can’t feel them. Lacquer or whatever you going to use, will make them reappear again. Wipe the surface with moist rag to see the pores again.

It could be that you sanded the veneer through to the glue line. That would be bad but I hope it’s not the case. If it is oh well - wire brush.

ProAc aren’t using any special lacquer. Any commercial speaker manufacturer, just as if a furniture manufacturer is limited to a cost involved in to finishing. Cabinets have to look as good as possible and as cheap as possible. There’s no magic, no campaign and no secret sound absorbing military grade lacquer. There are also minimum of handwork involved in producing these cabinets. No gnomes running around the factory with witch hazel, opening the grain. I’ve done this finish quite a few times. The variations come from the type lacquer. Some environmentally friendly companies are switching to water base lacquers or polyurethane.

It could be that you sanded the veneer through to the glue line. That would be bad but I hope it’s not the case. If it is oh well - wire brush.

ProAc aren’t using any special lacquer. Any commercial speaker manufacturer, just as if a furniture manufacturer is limited to a cost involved in to finishing. Cabinets have to look as good as possible and as cheap as possible. There’s no magic, no campaign and no secret sound absorbing military grade lacquer. There are also minimum of handwork involved in producing these cabinets. No gnomes running around the factory with witch hazel, opening the grain. I’ve done this finish quite a few times. The variations come from the type lacquer. Some environmentally friendly companies are switching to water base lacquers or polyurethane.

Thanks again. My first thought was that the pores I could see were

probably distributed throughout the wood which was why I was

shocked to see them vanish. But I've just checked again and

surprisingly they look fine now! Either I didn't look properly before

or perhaps the wood's dried out more since I wet sanded and

stained it and this has re-revealed them. Anyway, problem solved.

I totally agree with the observation that the ProAc's are

manufactured, like everything else, in a way they minimises

construction effort. I know nothing about wood (metal yes, but

wood is strange imprecise stuff!) but the general structure and

electrical construction of my Tablette 2000's looks very ordinary to

me.

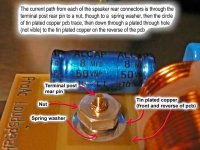

I was particularly disappointed to note that the current paths in

from the huge golden coloured connectors on the back are through

single tiny steel spring washers to the tin plated copper pcb traces!

They're on the wrong side of the pcb too so the first thing a current

has to do is pass back down a plated through hole! It makes

manufacture straight forward but also makes a mockery of the use

of huge connectors and all those 'magical' tweaks people believe

improve their HiFi's! So that makes me wonder if my ProAcs (which I

got dirt cheap by the way due to one having a blown woofer) are

really that good or have I just been hypnotised by the brand

image? I hate the thought I might just be a techno-fashion victim!

Talking of which, I've noticed that the car spray paints I've been

looking at all seem to be acrylic rather than cellulose nitrate. I hope

that gives a technological advancement in the paint finish rather

than just a reduction in manufacturing cost?

BB

probably distributed throughout the wood which was why I was

shocked to see them vanish. But I've just checked again and

surprisingly they look fine now! Either I didn't look properly before

or perhaps the wood's dried out more since I wet sanded and

stained it and this has re-revealed them. Anyway, problem solved.

I totally agree with the observation that the ProAc's are

manufactured, like everything else, in a way they minimises

construction effort. I know nothing about wood (metal yes, but

wood is strange imprecise stuff!) but the general structure and

electrical construction of my Tablette 2000's looks very ordinary to

me.

I was particularly disappointed to note that the current paths in

from the huge golden coloured connectors on the back are through

single tiny steel spring washers to the tin plated copper pcb traces!

They're on the wrong side of the pcb too so the first thing a current

has to do is pass back down a plated through hole! It makes

manufacture straight forward but also makes a mockery of the use

of huge connectors and all those 'magical' tweaks people believe

improve their HiFi's! So that makes me wonder if my ProAcs (which I

got dirt cheap by the way due to one having a blown woofer) are

really that good or have I just been hypnotised by the brand

image? I hate the thought I might just be a techno-fashion victim!

Talking of which, I've noticed that the car spray paints I've been

looking at all seem to be acrylic rather than cellulose nitrate. I hope

that gives a technological advancement in the paint finish rather

than just a reduction in manufacturing cost?

BB

Attachments

Welcome to the wonderful world of commercial loudspeakers. You forget to mention a 15c electrolytic capacitor there.

Car paints have different expansion-contraction properties then wood paints. They are usually more expensive then a majority of wood coatings. Basically, they design to stick to metal and hold up to the sun, rain and bird droppings.

The reason, I suggested NC is because 99% of cabinet factories (and ProAc either has their own factory or sub out cabinet work to someone local) will use it for price-value relationship and easy (in commercial environment) application. It dries fast, gives good enough scratch resistance and it’s cheap. The next step or I should say upgrade is Pre catalyzed NC. The application involves more precision and it’s very sensitive to the thickness of coating. Another words, you spray too much, it’ll spider crack. However, better scratch resistance and only 3 coats needed to achieve a nice finish.

Looking at the crossover picture, I would guess that ProAc is extremely budget oriented and it’s probably just NC. Can’t say a 100% without running a test.

I have to mention that not all of these coatings are compatible with each other. Acrylic lacquer may pill off from NC base after a while. It may not. Either way, wet sanding wood is overkill and you may find out a hard way how good the veneer job on that cabinet is. 220 or 320 are perfectly fine.

Car paints have different expansion-contraction properties then wood paints. They are usually more expensive then a majority of wood coatings. Basically, they design to stick to metal and hold up to the sun, rain and bird droppings.

The reason, I suggested NC is because 99% of cabinet factories (and ProAc either has their own factory or sub out cabinet work to someone local) will use it for price-value relationship and easy (in commercial environment) application. It dries fast, gives good enough scratch resistance and it’s cheap. The next step or I should say upgrade is Pre catalyzed NC. The application involves more precision and it’s very sensitive to the thickness of coating. Another words, you spray too much, it’ll spider crack. However, better scratch resistance and only 3 coats needed to achieve a nice finish.

Looking at the crossover picture, I would guess that ProAc is extremely budget oriented and it’s probably just NC. Can’t say a 100% without running a test.

I have to mention that not all of these coatings are compatible with each other. Acrylic lacquer may pill off from NC base after a while. It may not. Either way, wet sanding wood is overkill and you may find out a hard way how good the veneer job on that cabinet is. 220 or 320 are perfectly fine.

Update

Ok, things have moved on a little:

I tracked down Mohawk Lacquer Enamel in the UK to

http://www.mohawk-finishing.co.uk/faq.htm

But they sell to trade in boxes of 12.

Instead they pointed me to "an identical product", which I guess is

the same stuff rebranded.

http://www.behlen.co.uk/Merchant2/m...Code=B101-S826&Category_Code=AERPIGMENTREPAIR

However they have a minimum order of £20 and charge over £9 for

postage

making the order about US$60, but I couldn't find nitrocellulose

lacquer anywhere else so I went for it.

Meanwhile I contacted ProAcs Richard at Modaudio@aol.com

He said "The speakers are stained not spray painted".

This was annoying obviously as I originally thought they were

stained but had now spent a packet on paint. Asking for more detail

as to the nature of the stain I was told, "I've never attempted to

repair or stain speakers. I've always relied on a professional who

refinishes and repairs cabinets to do the work. They can match the

color with greater accuracy," so I'm not even sure how much

detailed knowledge underlies his original claim that they were

stained.

I also contacted ProAc in the UK but had no reply.

Shame. They were almost chatty when I wanted to give them £100

for a new woofer a few weeks ago 🙄

Looks like I'm going to be doing some experimenting then, I guess!

BB

Ok, things have moved on a little:

I tracked down Mohawk Lacquer Enamel in the UK to

http://www.mohawk-finishing.co.uk/faq.htm

But they sell to trade in boxes of 12.

Instead they pointed me to "an identical product", which I guess is

the same stuff rebranded.

http://www.behlen.co.uk/Merchant2/m...Code=B101-S826&Category_Code=AERPIGMENTREPAIR

However they have a minimum order of £20 and charge over £9 for

postage

making the order about US$60, but I couldn't find nitrocellulose

lacquer anywhere else so I went for it.

Meanwhile I contacted ProAcs Richard at Modaudio@aol.com

He said "The speakers are stained not spray painted".

This was annoying obviously as I originally thought they were

stained but had now spent a packet on paint. Asking for more detail

as to the nature of the stain I was told, "I've never attempted to

repair or stain speakers. I've always relied on a professional who

refinishes and repairs cabinets to do the work. They can match the

color with greater accuracy," so I'm not even sure how much

detailed knowledge underlies his original claim that they were

stained.

I also contacted ProAc in the UK but had no reply.

Shame. They were almost chatty when I wanted to give them £100

for a new woofer a few weeks ago 🙄

Looks like I'm going to be doing some experimenting then, I guess!

BB

Hi,

Like it has been posted above several times, this is not a stain finish. Clearly, the person you talked to didn't know the difference.

No need for you to feel annoyed.

Like it has been posted above several times, this is not a stain finish. Clearly, the person you talked to didn't know the difference.

No need for you to feel annoyed.

I love salesman. Just love them. If you were in NY, I’d fix your speaker for $50 just to make a point. I think, I have some black satin lacquer in the cabinet; hell, I’d fix it free.

Behlen is exactly the same thing as Mohawk. It’s somewhat expensive in GB. I always go and get a can for $7 in local store.

Behlen is exactly the same thing as Mohawk. It’s somewhat expensive in GB. I always go and get a can for $7 in local store.

OK, Thanks guys, I'm glad my purchase wasn't a waste. 🙂

I'll be back after I've done some spraying and tell how I got on...

BB

I'll be back after I've done some spraying and tell how I got on...

BB

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Repairing Black Ash veneer