Linn has once again implemented a different approach in their models LK2-80 and Klout to avoid relay contact in series to the speakers: a power voltage regulator in the pos. and neg. rail and interruption of the voltage supply in the event of an error.

Unfortunately I haven't check out from which offset voltage at the output the voltage supply was interrupted.

Since some bass driver voice coils on these power amplifiers burned out, as I heard a few times (although very rarely), there was no reliable protection for the speakers present on this power amp models.

In the meantime my favorite speaker protect against DC are AC coupled power amplifiers, i. e. non symmetric voltage supply (neg. pole on GND) with serial capacitor in the pad to the speaker.

Unfortunately I haven't check out from which offset voltage at the output the voltage supply was interrupted.

Since some bass driver voice coils on these power amplifiers burned out, as I heard a few times (although very rarely), there was no reliable protection for the speakers present on this power amp models.

In the meantime my favorite speaker protect against DC are AC coupled power amplifiers, i. e. non symmetric voltage supply (neg. pole on GND) with serial capacitor in the pad to the speaker.

We are talking speaker protection here, avoiding a catastrophic event which may and will burn expensive and hard to replace speakers, not the important but mild job of pop/thump suppression.

We will have simultaneous high voltage and current, the worst combination.

All power supply can supply.

Admittedly, not every day buy "only once", when shorted amplifier happens.

IF interrupting it irretrievably burns relay contacts or at least its plating, so be it, we replace the relay too, a few bucks mean little vs. a burnt speaker cost and inconvenience.

In my book, best are relays using a "silver button", a part with a certain mass to it, at each contact surface.

Just "plating", any metal you choose, is atoms thick by definition.

We will have simultaneous high voltage and current, the worst combination.

All power supply can supply.

Admittedly, not every day buy "only once", when shorted amplifier happens.

IF interrupting it irretrievably burns relay contacts or at least its plating, so be it, we replace the relay too, a few bucks mean little vs. a burnt speaker cost and inconvenience.

In my book, best are relays using a "silver button", a part with a certain mass to it, at each contact surface.

Just "plating", any metal you choose, is atoms thick by definition.

Hi JMFahey,

I agree. However, if they include a relay for protection, they will obviously use it for thump elimination as well. That's just good engineering practice as it stops the speakers from ever seeing a large DC offset. THere is always a time element involved.

Plating is perfectly fine, reasonably thick in a quality relay. Atoms thick in the really cheap ones. Silver button types are rare, expensive and not required. I don't think I have seen one in eons, or ever in a consumer piece. Heavier "relays" are called contactors.

I agree with most of what you are saying. Relays are a maintenance item, simple. If you run audio while the amplifier turns on or off, you will burn the contacts a bit each time. Then you will need more maintenance. Honestly, everything does need periodic maintenance anyway. A relay is merely another part. You've got idiots replacing all capacitors, a relay is minor by comparison.

I agree. However, if they include a relay for protection, they will obviously use it for thump elimination as well. That's just good engineering practice as it stops the speakers from ever seeing a large DC offset. THere is always a time element involved.

Plating is perfectly fine, reasonably thick in a quality relay. Atoms thick in the really cheap ones. Silver button types are rare, expensive and not required. I don't think I have seen one in eons, or ever in a consumer piece. Heavier "relays" are called contactors.

I agree with most of what you are saying. Relays are a maintenance item, simple. If you run audio while the amplifier turns on or off, you will burn the contacts a bit each time. Then you will need more maintenance. Honestly, everything does need periodic maintenance anyway. A relay is merely another part. You've got idiots replacing all capacitors, a relay is minor by comparison.

Some contacts are offered with Tungsten/ Cadmium/ Beryllium alloyed with copper on the buttons for longer life.

Silver plating or alloy is also known to be used.

But a relay is still a consumable maintenance item, more so if a smaller than needed rating was used in the first place to cut costs.

Silver plating or alloy is also known to be used.

But a relay is still a consumable maintenance item, more so if a smaller than needed rating was used in the first place to cut costs.

An article from OMRON

https://components.omron.com/us-en/products/relays/mosfet-relays/mosfet-relay_features

https://components.omron.com/us-en/products/relays/mosfet-relays/mosfet-relay_features

Last edited:

Sorry Chris, that may be an article they published, but without any form of numbers, conditions or anything else, it is useless and cannot even be classified as information.

By chance, did you look at the graph above it showing the mechanical relay is superior? This is what we would call a "white paper" or straight advertising copy. It is about as useful as toilet paper, well only if it was printed and it would not be something I would want to use.

If you are going to repeat something, assess it first please. This hardly qualifies for any sort of proof, and it only goes to show that Omron is now in the speaker relay business. They have substantial commercial interest, but if they had numbers and test conditions that were truly favourable, you can bet they would be front and centre. The fact that information is missing is very telling.

By chance, did you look at the graph above it showing the mechanical relay is superior? This is what we would call a "white paper" or straight advertising copy. It is about as useful as toilet paper, well only if it was printed and it would not be something I would want to use.

If you are going to repeat something, assess it first please. This hardly qualifies for any sort of proof, and it only goes to show that Omron is now in the speaker relay business. They have substantial commercial interest, but if they had numbers and test conditions that were truly favourable, you can bet they would be front and centre. The fact that information is missing is very telling.

Omron is tryting to enter that business, but they do not make Mosfets, so anybody can make those.

Analogy to lights business: as we shift to LED, we see that only Philips and Osram have stood up to competition, the big names in LED have little background in the expensive glass based older generation light sources, glass melting and extrusion / blowing plants are huge investments.

LEDs... a few youngsters with soldering and pressing equipment will put you in business, all the components are sold at very competitive rates.

Investment is low, silly money compared to what it takes to set up a glass based lighting source plant.

Philips Lighting is now Signify, GE has named its light business Current after spinning it off, and so on.

Now Omron will have to convince their potential customers, most likely in China, that coffee made by them is better than coffee made with the same beans by their competition...that is what it boils down to.

Analogy to lights business: as we shift to LED, we see that only Philips and Osram have stood up to competition, the big names in LED have little background in the expensive glass based older generation light sources, glass melting and extrusion / blowing plants are huge investments.

LEDs... a few youngsters with soldering and pressing equipment will put you in business, all the components are sold at very competitive rates.

Investment is low, silly money compared to what it takes to set up a glass based lighting source plant.

Philips Lighting is now Signify, GE has named its light business Current after spinning it off, and so on.

Now Omron will have to convince their potential customers, most likely in China, that coffee made by them is better than coffee made with the same beans by their competition...that is what it boils down to.

Last edited:

Hi NareshBrd,

Yes.

However my main point is that the fancy Omron page has zero verifiable information. It is basically an ad, nothing more, and it is making unverified claims.

I would love nothing more than a reliable replacement for relays that perform as well as a relay for connection. Heck, I'll be adopting those right away! But the deal is, anything that detracts from the performance of an amplifier simply doesn't cut it. Solid state replacements are not there yet. Are they better than a damaged relay - YES! But then almost anything is better than a damaged relay. Solution? Replace the damaged relay.

Yes.

However my main point is that the fancy Omron page has zero verifiable information. It is basically an ad, nothing more, and it is making unverified claims.

I would love nothing more than a reliable replacement for relays that perform as well as a relay for connection. Heck, I'll be adopting those right away! But the deal is, anything that detracts from the performance of an amplifier simply doesn't cut it. Solid state replacements are not there yet. Are they better than a damaged relay - YES! But then almost anything is better than a damaged relay. Solution? Replace the damaged relay.

So far any mosfet type connection I have tested has added distortion to very high quality amplifiers.

you have stated similar comments several times in this thread, without further details.

Hi ctrix,

Correct. I have said that I have personally tested them, and I know semiconductors quite well. Has anyone else stated this here (personally tested)?

I'm not going to debate on those grounds. However if you're going to link to a "source" as proof, it had better have test conditions and other specifics. You see, relays are time proved, there is absolutely no shortage of actual performance data on the web easily obtainable. I took it further for myself when Mosfet types came out. So if you want to tell anyone you have a superior way of doing things ... then PROVE IT.

The op asked about the best relay. Others are digging up alternatives, which is fine, but the onus is on them to prove it.

Now I did state that Mosfet type switches do perform okay. So if you have an amplifier that performs "okay", these may be "okay" to use. With some amplifiers I work on, these are not okay at all. This is all I have said. I also said that if I ever test ones reasonable in cost (compared to a relay) that are as good, I will use them. I don't know what more you want from me. I bought and paid for a few to try, but I am not going to bankroll the material costs and time to prove the case for Mosfet switches. Show me, don't make me work to prove your case.

Anyway, a debate for the sake of a debate isn't in the cards. I don't have the time, and my time has value.

Correct. I have said that I have personally tested them, and I know semiconductors quite well. Has anyone else stated this here (personally tested)?

I'm not going to debate on those grounds. However if you're going to link to a "source" as proof, it had better have test conditions and other specifics. You see, relays are time proved, there is absolutely no shortage of actual performance data on the web easily obtainable. I took it further for myself when Mosfet types came out. So if you want to tell anyone you have a superior way of doing things ... then PROVE IT.

The op asked about the best relay. Others are digging up alternatives, which is fine, but the onus is on them to prove it.

Now I did state that Mosfet type switches do perform okay. So if you have an amplifier that performs "okay", these may be "okay" to use. With some amplifiers I work on, these are not okay at all. This is all I have said. I also said that if I ever test ones reasonable in cost (compared to a relay) that are as good, I will use them. I don't know what more you want from me. I bought and paid for a few to try, but I am not going to bankroll the material costs and time to prove the case for Mosfet switches. Show me, don't make me work to prove your case.

Anyway, a debate for the sake of a debate isn't in the cards. I don't have the time, and my time has value.

Thanks Chris, and there is my point. I measure amplifiers that use regular relays with very low distortion.

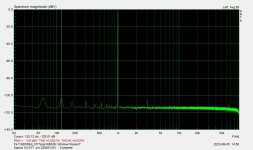

This is an actual measurement using and RTX 6001 and standard 8R Dale 250W, 1% non-inductive resistors on a heatsink using a Kelvin connection. Nothing special in wiring. The connection to the load is a stereo speakon connector. Normal 16 ga wire, zip cord style and this was pins into the stock spring terminal wires. 2.83 Vac (1 watt) across the load measured using a Keysight 34465A meter. I have MI, but ARTA is easier and quicker to use, I paid license for it in case there are any questions.

The amplifier in question is a mostly stock Sansui AU-517, so should I have run that nice signal through a mosfet switch?

This is an actual measurement using and RTX 6001 and standard 8R Dale 250W, 1% non-inductive resistors on a heatsink using a Kelvin connection. Nothing special in wiring. The connection to the load is a stereo speakon connector. Normal 16 ga wire, zip cord style and this was pins into the stock spring terminal wires. 2.83 Vac (1 watt) across the load measured using a Keysight 34465A meter. I have MI, but ARTA is easier and quicker to use, I paid license for it in case there are any questions.

The amplifier in question is a mostly stock Sansui AU-517, so should I have run that nice signal through a mosfet switch?

Attachments

One thought...anybody tried MOV as arc suppressor on an audio relay?

I had used them on relays controlling contators, and contactors controlling 0.22 / 2 / 3 kW heaters, on my molding machine, arc suppression and life improvement of 3-4 x was evident.

When they wore out, I used to replace the relays, and change contactor contact sets.

Now the new PLC uses SSR, so removed from service.

But will that work on a speaker relay?

As for Omron, maybe it was a wet finger in the wind, to judge market response.

But the way Anatech gave details of his equipment and test conditions, verifiable, and capable of being replicated elsewhere, that is the real deal when it comes to test setups.

Without data regarding test (even saying that it is to a RIAA or ANSI standard, for example, is enough), it amounts to BS, not expected from such a reputed company.

I had used them on relays controlling contators, and contactors controlling 0.22 / 2 / 3 kW heaters, on my molding machine, arc suppression and life improvement of 3-4 x was evident.

When they wore out, I used to replace the relays, and change contactor contact sets.

Now the new PLC uses SSR, so removed from service.

But will that work on a speaker relay?

As for Omron, maybe it was a wet finger in the wind, to judge market response.

But the way Anatech gave details of his equipment and test conditions, verifiable, and capable of being replicated elsewhere, that is the real deal when it comes to test setups.

Without data regarding test (even saying that it is to a RIAA or ANSI standard, for example, is enough), it amounts to BS, not expected from such a reputed company.

Hi NareshBrd,

The problem with an MOV is that it conducts when it breaks down (fault condition), connecting the load (speaker) to the amplifier output. We want to avoid this. I use MOVs across the power transformer primary where it greatly extends power switch life, and protects against surges. Neat eh?

The best solution would be a mute relay that operates before the output relay opens, and releases after the output relay closes. The average person cannot be trusted to turn the volume down when switching the system on or off. Those people typically complain the most when they have to replace speaker relays! lol!

I do use MOVs across paging speaker lines that run above ground at times. Choose them to be well above the maximum audio voltage you expect, with me that would be across a 70V line on the load side. This is in a factory campus setting where I may have racks of amplifiers (sometimes over 10). For above ground runs, I recommend a relay system that leaves amplifiers normally disconnected, and only connects them when you are paging (the page signal trips the controller to turn the relays on). That saves many amplifiers from horrible failures due to lightning strike impulses. Note lightning does not have to strike the speaker feed line to create a huge (destructive) pulse. The feed line is a big antenna.

In a tube amplifier, you could place an MOV across each plate to B+ feed. It would conduct if the speaker load was disconnected, saving the output transformer and possibly output tube from destruction. I always recommend a screwed terminal connection for tube amplifier outputs, never a banana or other easily disconnected type of connector.

The problem with an MOV is that it conducts when it breaks down (fault condition), connecting the load (speaker) to the amplifier output. We want to avoid this. I use MOVs across the power transformer primary where it greatly extends power switch life, and protects against surges. Neat eh?

The best solution would be a mute relay that operates before the output relay opens, and releases after the output relay closes. The average person cannot be trusted to turn the volume down when switching the system on or off. Those people typically complain the most when they have to replace speaker relays! lol!

I do use MOVs across paging speaker lines that run above ground at times. Choose them to be well above the maximum audio voltage you expect, with me that would be across a 70V line on the load side. This is in a factory campus setting where I may have racks of amplifiers (sometimes over 10). For above ground runs, I recommend a relay system that leaves amplifiers normally disconnected, and only connects them when you are paging (the page signal trips the controller to turn the relays on). That saves many amplifiers from horrible failures due to lightning strike impulses. Note lightning does not have to strike the speaker feed line to create a huge (destructive) pulse. The feed line is a big antenna.

In a tube amplifier, you could place an MOV across each plate to B+ feed. It would conduct if the speaker load was disconnected, saving the output transformer and possibly output tube from destruction. I always recommend a screwed terminal connection for tube amplifier outputs, never a banana or other easily disconnected type of connector.

Anatech, thanks for the detailed information.

I have put a 275V / 20 mm MOV, phase to neutral on my house mains, effective high voltage and arc quencher.

About 15 years now, it works.

I have put a 275V / 20 mm MOV, phase to neutral on my house mains, effective high voltage and arc quencher.

About 15 years now, it works.

A MOV (Metal Oxid Varistor) - go toOne thought...anybody tried MOV as arc suppressor on an audio relay?

I had used them on relays controlling contators, and contactors controlling 0.22 / 2 / 3 kW heaters, on my molding machine, arc suppression and life improvement of 3-4 x was evident.

When they wore out, I used to replace the relays, and change contactor contact sets.

Now the new PLC uses SSR, so removed from service.

But will that work on a speaker relay?

As for Omron, maybe it was a wet finger in the wind, to judge market response.

But the way Anatech gave details of his equipment and test conditions, verifiable, and capable of being replicated elsewhere, that is the real deal when it comes to test setups.

Without data regarding test (even saying that it is to a RIAA or ANSI standard, for example, is enough), it amounts to BS, not expected from such a reputed company.

https://www.eska-fuses.de/fileadmin/produkte/datenblaetter/ESKA_MOV_Varistoren.pdf

for speaker protect ? This I haven't heard until now; this parts provide only surge protection for AC and DC voltage - as I know.

Even NTC resistors, go to

https://www.ametherm.com/inrush-current/standard-surge-limiter/

usual used as an inrush current limiter part for large toroidal power transformers I never see as parts for speaker protect.

Only polyfuses (resettable fuses) - go to

https://www.littelfuse.com/products/polyswitch-resettable-pptcs.aspx

and to the attached files, I have seen for speaker protect in the Amps from Anders Thule (Thule Audio "SPIRIT" series) and any few models from Primare in series to the speaker rail.

Attachments

This was the main reason for the choice of mentioned SDS relay mentioned in my posts #37/38.The best solution would be a mute relay that operates before the output relay opens, and releases after the output relay closes. The average person cannot be trusted to turn the volume down when switching the system on or off. Those people typically complain the most when they have to replace speaker relays! lol!

The use of a mute relay anywhere in front of the output relay sounds good, but has this approach ever been implemented in a commercial available amp device?

Hi tiefbassuebertr,

You can't easily defeat a person who is determined to be lazy or thoughtless. Trying to do this is what society is all about right now. It simply doesn't work. People will do stupid things that cause damage no matter what you do. Trying to prevent this costs massive amounts of money, and that is because there really is no easy way out in normal life. So while a solid state relay is a great concept, it negatively impacts performance. Education and teaching people they have to be responsible for their own actions applies to all aspects of life. Everything between driving and how you conduct yourself with others, right down to turning a stereo on and off.

The mute relay would operate on the input signal to the amplifier. It would be of the type that shorts the signal to common. This would not impact audio performance in any way while protecting the output relay contacts against stupidity. It also adds cost to the final product. That's why you don't see this in use.

You can't easily defeat a person who is determined to be lazy or thoughtless. Trying to do this is what society is all about right now. It simply doesn't work. People will do stupid things that cause damage no matter what you do. Trying to prevent this costs massive amounts of money, and that is because there really is no easy way out in normal life. So while a solid state relay is a great concept, it negatively impacts performance. Education and teaching people they have to be responsible for their own actions applies to all aspects of life. Everything between driving and how you conduct yourself with others, right down to turning a stereo on and off.

The mute relay would operate on the input signal to the amplifier. It would be of the type that shorts the signal to common. This would not impact audio performance in any way while protecting the output relay contacts against stupidity. It also adds cost to the final product. That's why you don't see this in use.

- Home

- Design & Build

- Parts

- relay for speaker protection: what's the important rating in this application?