Very simply, you want one rated for 120/240 VAC anyway (a common rating as most are for Mains use). The next thing is current rating. Too light and the contacts may melt in a fault and short together. You need it to interrupt the current.

Commonly, 5A should do most amplifiers just fine as you aren't interrupting this, just conducting while closed. Contactors are different, higher current ratings and they may run the signal through the swing arms leading to distortion. So don't mindlessly just go for the highest current rating you can get. Little amp, 3 ampere contacts are fine. A large amplifier (100 watts +) should be using 10 ampere contacts.

Make sure there is no audio when you power the amplifier on or off. That will burn the contacts. Also understand that relays are a maintenance item. Periodically they should be replaced. They may last you 40 years or a few months depending on how you tread them and the quality.

Commonly, 5A should do most amplifiers just fine as you aren't interrupting this, just conducting while closed. Contactors are different, higher current ratings and they may run the signal through the swing arms leading to distortion. So don't mindlessly just go for the highest current rating you can get. Little amp, 3 ampere contacts are fine. A large amplifier (100 watts +) should be using 10 ampere contacts.

Make sure there is no audio when you power the amplifier on or off. That will burn the contacts. Also understand that relays are a maintenance item. Periodically they should be replaced. They may last you 40 years or a few months depending on how you tread them and the quality.

@anatech "Make sure there is no audio when you power the amplifier on or off. That will burn the contacts. Also understand that relays are a maintenance item. Periodically they should be replaced. They may last you 40 years or a few months depending on how you tread them and the quality."

wouldn't this be eliminated by using a relay with higher amp rating? thanks again

wouldn't this be eliminated by using a relay with higher amp rating? thanks again

Hi,

No, sorry. When the contacts open, an arc will burn the plating. Contacts bounce when they close. I'm afraid you have to be aware of what you are doing.

Understand the plating is extremely thin. One issue with larger contacts is the contact pressure per unit area is lower. Once the plating is burned, the contact is done. The base metal doesn't make good connections. So filing instantly destroys relay contacts (contactors are different and handle power voltage).

No, sorry. When the contacts open, an arc will burn the plating. Contacts bounce when they close. I'm afraid you have to be aware of what you are doing.

Understand the plating is extremely thin. One issue with larger contacts is the contact pressure per unit area is lower. Once the plating is burned, the contact is done. The base metal doesn't make good connections. So filing instantly destroys relay contacts (contactors are different and handle power voltage).

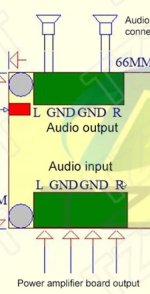

Relay for speaker protection:

what's the important rating in this application?

https://neurochrome.com/products/guardian-86

Circuit Description:

The main design challenge of a speaker protection circuits is the design of the switch itself. The switch must be able to handle low voltages with high fidelity and be able to switch the large output current. These requirements are in conflict as the low-voltage switching tends to be best accomplished by gold switch points, but those points will vaporize if they are used at the high current levels commonly found in audio amplifiers. While it is possible to design a relay with two contact sets in parallel – one optimized for low voltage the other for high current – a much more elegant solution is to use a solid-state switch, such as a MOSFET...

I am aware of that option, and I have measured them before. I wish this was an answer.

The unit has a relay available that fits exactly. Use it.

The unit has a relay available that fits exactly. Use it.

Use the best quality, and the highest possible current rating in that type of relay.

Some brands have different max. ratings, check them out.

Price difference will be negligible between 5A and 10A relays, use a brand that actually takes that, some brands can be over-optimistic.

And you must know what you are doing before going for other options, not a newbie job.

Stick to what is provided on board.

Some brands have different max. ratings, check them out.

Price difference will be negligible between 5A and 10A relays, use a brand that actually takes that, some brands can be over-optimistic.

And you must know what you are doing before going for other options, not a newbie job.

Stick to what is provided on board.

The DC switching voltage rating has to be high enough, because you want it to be able to disconnect the loudspeakers when due to some fault, the supply voltage ends up at the output. Switching off DC is more difficult than switching off AC because there are no zero crossings in which the arc disappears, hence DC switching voltage ratings are often much lower than the AC ratings.

Last edited:

What was the exact problem with that option?I am aware of that option, and I have measured them before. I wish this was an answer.

The unit has a relay available that fits exactly. Use it.

IMO, paralleling relay contacts for speaker protection circuits is always a good idea, it reduces contact resistance and if you can connect three sets of contacts in parallel, one set of contacts will always have minimal stress. However, each contact must be able to handle the rated power requirements, unless you can control the engage/release timing like the Amplimo LRZ relay does.

OP: current rating is very important. But voltage rating can be too if the amp is reasonably high power, partly because a failed output semiconductor will challenge the relay with DC, which is more prone to arcing.

There is some info concerning protection relays over on the ESP site here (a bit in the intro, then scroll down to the 'relay specifications' section), which sees relevent to the questions being asked. Lower down still on that page there is is also some stuff here on their failure and on wiring contacts in series for high voltage. He also uses double-throw/change-over types with the 'off' pin connected to ground, which in some cases can help to break an arc.

I believe he also has mosfet alternatives and a mosfet/relay hybrid offering on his site, but I haven't looked them in any detail myself so can't comment on those.

There is some info concerning protection relays over on the ESP site here (a bit in the intro, then scroll down to the 'relay specifications' section), which sees relevent to the questions being asked. Lower down still on that page there is is also some stuff here on their failure and on wiring contacts in series for high voltage. He also uses double-throw/change-over types with the 'off' pin connected to ground, which in some cases can help to break an arc.

I believe he also has mosfet alternatives and a mosfet/relay hybrid offering on his site, but I haven't looked them in any detail myself so can't comment on those.

how do I test if the speaker protection device works? Is it by introducing a DC supply (example: 12V from a DC adapter for my network switch) into the right or left input pins and ground?

Oh for crying out loud! People, get a grip on reality!

This is a commercial product with a part that is available that fits exactly. The new part will operate for decades without trouble if treated properly. The ratings on the original part are marked on the case. The relay will be rated for mains voltage, because they simply are. The current rating is marked, use the same or a little higher.

The OP simply wants his equipment to operate properly again. Remember, Denon would not use a part that degraded performance or caused warranty problems. So stick the same thing back in.

-Chris

This is a commercial product with a part that is available that fits exactly. The new part will operate for decades without trouble if treated properly. The ratings on the original part are marked on the case. The relay will be rated for mains voltage, because they simply are. The current rating is marked, use the same or a little higher.

The OP simply wants his equipment to operate properly again. Remember, Denon would not use a part that degraded performance or caused warranty problems. So stick the same thing back in.

-Chris

Hi mrjayviper,

Don't do that. Period.

If I looked it up, I would find an IC supervisory circuit, like a TA7317P or similar. Or it may be discrete. The time out feature works, you proved that. If you force voltage in, you will probably blow up one channel at least, so just don't. Do not get creative!

Don't do that. Period.

If I looked it up, I would find an IC supervisory circuit, like a TA7317P or similar. Or it may be discrete. The time out feature works, you proved that. If you force voltage in, you will probably blow up one channel at least, so just don't. Do not get creative!

Hi kouiky,

I have measured them. So problems are:

You always have to consider reality. This goes for new design, and especially service. I do occasionally have to return equipment to "factory configuration" to make it work again after someone gets creative and executes a "better idea".

-Chris

I have measured them. So problems are:

- More expensive

- Changes in order to use them in existing equipment

- Higher on resistance than contacts (measured with Keysight DVMs in Kelvin mode). = lower damping factor if linear

- Measured distortion can be higher on very good equipment, with cheaper stuff it may not matter.

You always have to consider reality. This goes for new design, and especially service. I do occasionally have to return equipment to "factory configuration" to make it work again after someone gets creative and executes a "better idea".

-Chris

You can, but they are not low distortion.

no distortion here

Ready-to-Run (RTR) SSR DC Speaker Protection and Delay GB

- Home

- Design & Build

- Parts

- relay for speaker protection: what's the important rating in this application?