I'm trying to repair a pair of KLH AV5001 3-ways (12" woofer with 12" passive radiator, 3.5" cone midrange, and 0.88" dome tweeter) with blown tweeters.

These speakers are 1995 vintage and were built by KHL Audio Systems, the company that eventually acquired the KLH brand after the original company was sold a number of times. They are very cheaply made --- stamped woofer baskets, no cabinet bracing, no stuffing, spring-clip connectors, small gauge internal wiring, and the crossover circuitry is glued to the back of the terminal cup! I paid 98 bucks apiece for them at a local outlet store.

But they sound sound amazingly good, so they're worth repairing.

I think I've found a pair of replacement tweeters on eBay. But I'd like to rebuild the crossovers while I'm at it, add some bracing and stuffing, seal the boxes and drivers, and replace the terminal cups with 3-way binding posts.

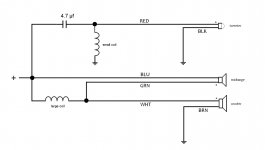

The prob is those crossovers. Each of them consists of only 2 coils and one 4.7uf cap, all glued to the back of the terminal cup. The coils appear to be hand-wound iron core jobs. I have no idea what their values might be. I've sketched what I think is the circuit diagram, but because most of the connections are covered in black glue, it's hard to tell what connects to what.

I've attached the circuit diagram and a photos of the actual unit. Questions:

1. Does the diagram as sketched even make sense? The tested electrical resistance of the woofer is 5 ohms, 10.8 on the midrange (if that tells you anything). Tweeters are 6 ohm nominal.

2. Notice on the photo that on each of the coils, the two leads are twisted together before proceeding to their respective connection points. Would that not effectively bypass those coils?

3. Can induction coils go bad? I plan to test the caps and replace them if they're off-spec. But apparently testing coils requires an oscilloscope. So do I need to worry about them?

Something caused those tweeters to fail, and I'm wondering whether it was a failure in the crossovers.

Thanks for any help!

These speakers are 1995 vintage and were built by KHL Audio Systems, the company that eventually acquired the KLH brand after the original company was sold a number of times. They are very cheaply made --- stamped woofer baskets, no cabinet bracing, no stuffing, spring-clip connectors, small gauge internal wiring, and the crossover circuitry is glued to the back of the terminal cup! I paid 98 bucks apiece for them at a local outlet store.

But they sound sound amazingly good, so they're worth repairing.

I think I've found a pair of replacement tweeters on eBay. But I'd like to rebuild the crossovers while I'm at it, add some bracing and stuffing, seal the boxes and drivers, and replace the terminal cups with 3-way binding posts.

The prob is those crossovers. Each of them consists of only 2 coils and one 4.7uf cap, all glued to the back of the terminal cup. The coils appear to be hand-wound iron core jobs. I have no idea what their values might be. I've sketched what I think is the circuit diagram, but because most of the connections are covered in black glue, it's hard to tell what connects to what.

I've attached the circuit diagram and a photos of the actual unit. Questions:

1. Does the diagram as sketched even make sense? The tested electrical resistance of the woofer is 5 ohms, 10.8 on the midrange (if that tells you anything). Tweeters are 6 ohm nominal.

2. Notice on the photo that on each of the coils, the two leads are twisted together before proceeding to their respective connection points. Would that not effectively bypass those coils?

3. Can induction coils go bad? I plan to test the caps and replace them if they're off-spec. But apparently testing coils requires an oscilloscope. So do I need to worry about them?

Something caused those tweeters to fail, and I'm wondering whether it was a failure in the crossovers.

Thanks for any help!

Attachments

Yes it makes sence, its not very nice as the midrange and the tweeter play all the high frequancies.1. Does the diagram as sketched even make sense? The tested electrical resistance of the woofer is 5 ohms, 10.8 on the midrange (if that tells you anything). Tweeters are 6 ohm nominal.

The glue can come loose and they start to vibrate. I imagin providing they dont get hot, glue on the outside might help, I think thier are many other tweeks to do before this.3. Can induction coils go bad? I plan to test the caps and replace them if they're off-spec. But apparently testing coils requires an oscilloscope. So do I need to worry about them?

Most likely some a low powered amplifier "clipped".Something caused those tweeters to fail, and I'm wondering whether it was a failure in the crossovers.

My opinion is that unless you have measuring equipment, finding a replacement speaker cone will be hard, unless you go DSP and active. Making a new crossover will be even harder to get perfect, but your not looking for perfect, your looking for good enough.

Doing this by ear only if you can adjust it very eaisly and take a good deal of time listening at different adjustments. So the quick and dirty solution, would suggest getting an estimate on the efficincy, get a more sensitive tweeter (nearly all will be is my guess), and put in a volume control (often called Lpads ?) in it.

The easiest way to make it sound much better in my opinion would be to brace the bass speakers box, and buy/build your self a small two way mini monitor with working tweeters and smaller mid bass units, then learn about cross overs, and make your self a cross over to the 12" bass units some where between 80 - 300 Hz, then you can keep the bass you like, but first you need to read up on making crossovers, decide if you go active or passive.

Regards

Owen

- Status

- Not open for further replies.