Hi All,

Using the GE 12AX7 datasheet as an example...

https://frank.pocnet.net/sheets/093/1/12AX7.pdf

...I'm wondering if I am reading it correctly.

Looking at "MAXIMUM RATINGS" and "CHARACTERISTICS AND TYPICAL OPERATION", is the Plate Voltage measured directly across the plate-cathode? Or is it equivalent to Ebb under "CLASS A RESISTANCE-COUPLED AMPLIFIER"?

Assuming Plate Voltage = Ebb. 100V should give about 80K plate resistance (in an ideal world). And looking at the 6th row in "CLASS A RESISTANCE-COUPLED AMPLIFIER", we are given the following resistor values:

Plate Resistor: 510K

Cathode Bias Resistor: 7.8K

At 90V Ebb the math gives us the approximate voltage drops:

Across Rp: 77V

Across Plate-Cathode: 12V

Across Rk: 1V

That gives us a 1V cathode bias, which equals the -1V grid voltage under "CHARACTERISTICS AND TYPICAL OPERATION" and everything is awesome.

But what confuses me is the verbiage. To me, "Plate Voltage" would be measured at the plate. Not at Ebb. I'm just looking for some reassurance that I am reading it correctly.

Thanks!

Using the GE 12AX7 datasheet as an example...

https://frank.pocnet.net/sheets/093/1/12AX7.pdf

...I'm wondering if I am reading it correctly.

Looking at "MAXIMUM RATINGS" and "CHARACTERISTICS AND TYPICAL OPERATION", is the Plate Voltage measured directly across the plate-cathode? Or is it equivalent to Ebb under "CLASS A RESISTANCE-COUPLED AMPLIFIER"?

Assuming Plate Voltage = Ebb. 100V should give about 80K plate resistance (in an ideal world). And looking at the 6th row in "CLASS A RESISTANCE-COUPLED AMPLIFIER", we are given the following resistor values:

Plate Resistor: 510K

Cathode Bias Resistor: 7.8K

At 90V Ebb the math gives us the approximate voltage drops:

Across Rp: 77V

Across Plate-Cathode: 12V

Across Rk: 1V

That gives us a 1V cathode bias, which equals the -1V grid voltage under "CHARACTERISTICS AND TYPICAL OPERATION" and everything is awesome.

But what confuses me is the verbiage. To me, "Plate Voltage" would be measured at the plate. Not at Ebb. I'm just looking for some reassurance that I am reading it correctly.

Thanks!

Plate Voltage is always the voltage measured between plate and cathode. Ebb is meant in this sheet as the Supply Voltage for the circuit where that tube is used.

So if in the MAXIMUM RATINGS the Plate Voltage is 300V

then this is the absolute maximum value that the voltage between plate and cathode can handle without the risk of being destroyed. This is for instance the case when the Supply Voltage is 300V and the tube is driven into cutoff.

Plate current is then zero and the Plate Voltage is equal the Supply Voltage because there is no voltage drop across both the plate resistance and the used cathode resistance.

If your application uses a Ebb (Supply Voltage) which is lower than 300V, there is no such problem that the plate voltage will exceed the Maximum Rating of 300V.

So if in the MAXIMUM RATINGS the Plate Voltage is 300V

then this is the absolute maximum value that the voltage between plate and cathode can handle without the risk of being destroyed. This is for instance the case when the Supply Voltage is 300V and the tube is driven into cutoff.

Plate current is then zero and the Plate Voltage is equal the Supply Voltage because there is no voltage drop across both the plate resistance and the used cathode resistance.

If your application uses a Ebb (Supply Voltage) which is lower than 300V, there is no such problem that the plate voltage will exceed the Maximum Rating of 300V.

I agree with Joe Alders except for one detail: the maximum is a design centre maximum rather than an absolute maximum, which means that the manufacturer has already taken some safety margins for normal mains voltage variations and component tolerances. According to a 1971 Philips pocketbook, which refers to I.E.C. publication 134:

"Design-centre ratings are limiting values of operating and environmental conditions applicable to a bogey electronic device* of a specified type as defined by its published data, and should not be exceeded under average conditions.

These values are chosen by the device manufacturer to provide acceptable serviceability of the device in average applications, taking responsibility for normal changes in operating conditions due to rated supply-voltage variation, equipment component spread and variation, equipment control adjustment, load variation, signal variation, environmental conditions, and variations or spread in the characteristics of all electronic devices.

The equipment manufacturer should design so that, initially, no design-centre value for the intended service is exceeded with a bogey electronic device* in equipment operating at the stated normal supply-voltage."

"Note*. A bogey tube is a tube whose characteristics have the published nominal values for the type."

"Design-centre ratings are limiting values of operating and environmental conditions applicable to a bogey electronic device* of a specified type as defined by its published data, and should not be exceeded under average conditions.

These values are chosen by the device manufacturer to provide acceptable serviceability of the device in average applications, taking responsibility for normal changes in operating conditions due to rated supply-voltage variation, equipment component spread and variation, equipment control adjustment, load variation, signal variation, environmental conditions, and variations or spread in the characteristics of all electronic devices.

The equipment manufacturer should design so that, initially, no design-centre value for the intended service is exceeded with a bogey electronic device* in equipment operating at the stated normal supply-voltage."

"Note*. A bogey tube is a tube whose characteristics have the published nominal values for the type."

Just to throw a spanner in the works, the humble 6V6GT has an anode - cathode maximum voltage of 315volts and we often run them for years at 450volts with no issues.

O.K. This comment: I agree.

But perhaps I can add that MAXIMUM RATINGS has everything to do with the life time of the tube.

Violation of those ratings will reduce its expected life time.

But perhaps I can add that MAXIMUM RATINGS has everything to do with the life time of the tube.

Violation of those ratings will reduce its expected life time.

Just to throw a spanner in the works, the humble 6V6GT has an anode - cathode maximum voltage of 315volts and we often run them for years at 450volts with no issues.

Oh, I am not surprised. But it definitively will shorted its life time.

Plate Voltage is always the voltage measured between plate and cathode. Ebb is meant in this sheet as the Supply Voltage for the circuit where that tube is used.

Got it. Thank you for the clarification. I was afraid that might be the case because that will bring me to another question:

How does one determine the approximate plate resistance at a voltage not given under TYPICAL OPERATION?

The aforementioned datasheet only gives us 2 examples at 100V and 250V. But using the resistor values in row 6 of "CLASS A RESISTANCE-COUPLED AMPLIFIER", and a Vbb of 90V, will certainly drop the plate voltage much lower than 90V.

I would think knowing the plate resistance under different operating parameters is going to be important to correctly cathode-bias the tube.

I assume I could extrapolate this info using the plate curves. Just not sure how. I would also think that I could physically run the tube at 0V bias and take direct measurements to get in the ball park. But that seems counter-intuitive.

Any tips to steer me in the right direction?

Thanks again!

Last edited:

Just to throw a spanner in the works, the humble 6V6GT has an anode - cathode maximum voltage of 315volts and we often run them for years at 450volts with no issues.

450 V supply voltage or 450 V anode-to-cathode bias voltage after heating up? Many small valves from Philips have a maximum specified anode voltage after heating up of 300 V, but 550 V when cold, both design centre ratings.

Got it. Thank you for the clarification. I was afraid that might be the case because that will bring me to another question:

How does one determine the approximate plate resistance at a voltage not given under TYPICAL OPERATION?

The aforementioned datasheet only gives us 2 examples at 100V and 250V. But using the resistor values in row 6 of "CLASS A RESISTANCE-COUPLED AMPLIFIER", and a Vbb of 90V, will certainly drop the plate voltage much lower than 90V.

I would think knowing the plate resistance under different operating parameters is going to be important to correctly cathode-bias the tube.

I assume I could extrapolate this info using the plate curves. Just not sure how. I would also think that I could physically run the tube at 0V bias and take direct measurements to get in the ball park. But that seems counter-intuitive.

Any tips to steer me in the right direction?

Thanks again!

For a triode, a shift in anode voltage of delta VA is ideally equivalent to a shift in grid voltage of delta VA/mu.

Besides, the transconductance and internal resistance are essentially determined by the anode bias current. That is, any two bias points that result in the same anode current and in a grid voltage low enough to keep the grid out of conduction (which typically means <= -1.3 V, although -1 V is apparently still OK for a 12AX7) result in essentially the same small-signal parameters.

....looking at the 6th row in "CLASS A RESISTANCE-COUPLED AMPLIFIER"....

Yuck!! What are you building? A $9.95 table radio? A tube hearing aid? That's about the worst "hi-fi" condition listed.

OK, roll with that. Ebb is your B Battery voltage (or power supply). At 90V we have no risk of trouble on a 300V Max tube. A 90V battery feeding a Resistance-Loaded amplifier, the plate voltage will be well below the 90V battery. "About half", 40%-70% for most happy values.

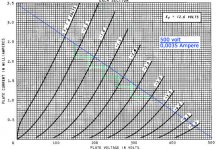

We "can" plot the operating point with 510k down from 90V and tracing the 7.8k cathode resistor across the grid lines. But this puts us so far down in the corner of the plate curves that we can hardly squint; also can't trust that the Jr Engineer really measured this corner or just drew smooth curves to zero.

With rough rules of thumb I estimated the actual working point. Something like 0.066mA. We can go to the graph on page 2 and try to find 0.066mA at 100V, then guess the adjustment for 55.5V. But even that is a real squint. I wrote my squints down but I know they won't be right. And will vary from one tube to another.

Do we really care? The datasheet assures us that 90V 510k 7k8 will "work", and gives results (these were probably Measured). Gain is good, but the load MUST be at least 1Meg. Typical stray capacitance tends to act like 200K at the top of the audio band, so we may not have full "hi-fi" bandwidth. 9V RMS seems OK next to typical hi-fi 1V level, but this is 5% THD. At 1V it may be 0.6%, at 2V it will be >1% THD. And this is one stage in a presumably larger System.

Attachments

Yuck!! What are you building? A $9.95 table radio? A tube hearing aid? That's about the worst "hi-fi" condition listed.

LoL. No. I’m not building that. I’m just running calculations on different operating parameters. I’m really trying to understand design theory.

There are good books around covering the basics.. First you got to determine the input voltage. For low distortion the delta E/delta I quotient needs to be regular. The ideal load can be calculated from the graph and you go from there.

Attachments

Last edited:

...trying to understand design theory.

Design starts from SPECIFICATIONS.

What does the thing have to do?

I hire you to design a bridge. Do you pull out catalogs of 2-foot high 50 foot long I-beams? Or bamboo poles? Preferably you quiz me: how long? how wide? Cars, oxen, people, mobs, or dogs? To last one event or "forever"?

Yes, in many "audio" cases we see the goals can be met with a half a 12AX7. At least in the *first* stages. It can drive short audio cables but not long ones, or not to a high standard. It can drive a couple 6V6 but not a quad of 6550. I've seen it used to drive a reverb tank, but Leo never used any less than both-half 12AT7.

So what do you want to do?

LoL. No. I’m not building that. I’m just running calculations on different operating parameters. I’m really trying to understand design theory.

As disco and PRR rightly have remarked: you first have to consider what you want to do with that tube in an amplifier stage and use the graphical method to make things easier.

If have made a small document to add as a little help.

Hope it will be of some value for you.

Attachments

What does the thing have to do?

I have this guitar amp:

What To Do With This Amp?

...and I'm trying to make it a functional, decent-sounding guitar amp. It had been frankensteined to death before I got it. It had a terrible hum. I tried a few suggested modifications, which helped a little. But I was still unable to remove all the hum and get a good sound from it.

So... I completely disassembled it. I don't typically approach a project assuming I will disassemble the entire thing. But components were soldered in with little forethought, the eyelet board needed replacing, and there were some unused PT secondary wires that were not capped. Yes. Bare ends of wires carrying AC voltage just floating around inside the chassis. I'm surprised this thing didn't turn into a flaming ball of smoke at some point. And I wouldn't be surprised if one of the previous techs that worked on it died from electrocution. On top of that, someone did a recap on it. But the lazy blockhead decided some of the caps were just too much trouble to replace.

I decided I was going to replace all the passive components that hadn't been replaced yet. All the resistors, volume and tone pots, and a handful of capacitors. I'm sure some of the existing resistors are out of tolerance and I also did not trust that any replaced components were optimal for the tube selection.

All that said, I have a 6SN7, 6V6, 6X5, a chassis, a really nice speaker, PT, OT, and a cool little cab. I hate to junk it all if something decent can be put together with it. So I'm trying to design a guitar amp around the components I have.

> I'm trying to design a guitar amp

_I_ say this bridge has been designed before. Find and steal (say "research") a known-good plan.

Rectifier, 6V6, twin-triode. Where have we seen this before? Fen....

{continued in other thread}

BTW: Leo Fender "designed" most amps from the same chart you have, only it was the Sylvania?? Somewhat different values, so we know which book was top of his pile.

_I_ say this bridge has been designed before. Find and steal (say "research") a known-good plan.

Rectifier, 6V6, twin-triode. Where have we seen this before? Fen....

{continued in other thread}

BTW: Leo Fender "designed" most amps from the same chart you have, only it was the Sylvania?? Somewhat different values, so we know which book was top of his pile.

Last edited:

> I'm trying to design a guitar amp

_I_ say this bridge has been designed before. Find and steal (say "research") a known-good plan.

Rectifier, 6V6, twin-triode. Where have we seen this before? Fen....

{continued in other thread}

BTW: Leo Fender "designed" most amps from the same chart you have, only it was the Sylvania?? Somewhat different values, so we know which book was top of his pile.

I thought the same. I did try looking for a schematic using this set of components. I didn't have much luck. Maybe I should try again.

Outside of that, I do understand what you are saying. But I am also not always content just being the builder. I do enjoy designing as well; and understanding the theory behind it. Are you suggesting this is simply too much for a "weekend warrior" to learn?

Replacing all components is a very good way of ruining almost any circuit. You should only replace what is faulty, then what is likely to become faulty. In an old amp that usually means CC resistors, paper dielectric caps and some electrolytics.

In an old amp that usually means CC resistors, paper dielectric caps and some electrolytics.

That is all I intend on replacing. But, as I mentioned, this amp had been fubar'd by a number of previous techs. Some components were replaced. Some not. Some I don't know. The existing resistors may be original values, or they may not. I really don't know. I only know that I don't trust any of the passive components to be original or correct value.

I found several schematics for this amp. But none use a 6SN7, 6V6, and 6X5. I also looked for ANY schematic using 6SN7 and 6V6 without much luck (but I'm still looking). So since I don't have a schematic, and I don't trust any of the previous work done, I feel my only recourse is to redesign around the tubes and transformers that I do have.

- Home

- Amplifiers

- Tubes / Valves

- Reading Datasheets