I'm not sure if this is the correct forum to post this in,if not,please move it😱

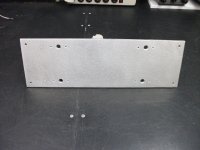

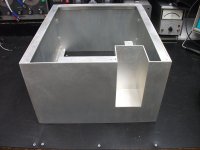

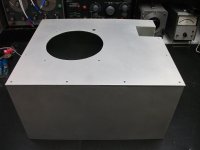

A while back I started an RCM project. It's based on the Loricraft/Keith Monk style. After building a cobbled-together prototype for validation,I've now begun the finalized version. The material is 0.125'' 5052 H36 aluminum for the housing and covers,0.25'' for the vacuum pump mounting plate.The housing was TIG welded together. All parts were chromated after finish sanding.Painting,probably black hammertone, will come after I complete a trial assembly. All work is entirely my own. For some reason (cheap borrowed camera!) all the edges appear bowed;this is NOT the case,all edges are square and true. I've also opted to include the catch-bottle in the assembly,rather than having it hanging off the side,attached by an elastic! I'll include updates as the build progresses.

The sheet metal was done at work while my crew was on their lunch break 😀

A while back I started an RCM project. It's based on the Loricraft/Keith Monk style. After building a cobbled-together prototype for validation,I've now begun the finalized version. The material is 0.125'' 5052 H36 aluminum for the housing and covers,0.25'' for the vacuum pump mounting plate.The housing was TIG welded together. All parts were chromated after finish sanding.Painting,probably black hammertone, will come after I complete a trial assembly. All work is entirely my own. For some reason (cheap borrowed camera!) all the edges appear bowed;this is NOT the case,all edges are square and true. I've also opted to include the catch-bottle in the assembly,rather than having it hanging off the side,attached by an elastic! I'll include updates as the build progresses.

The sheet metal was done at work while my crew was on their lunch break 😀

Attachments

-

DSCF2116.JPG204.1 KB · Views: 307

DSCF2116.JPG204.1 KB · Views: 307 -

DSCF2119.JPG281.5 KB · Views: 300

DSCF2119.JPG281.5 KB · Views: 300 -

DSCF2120.JPG220 KB · Views: 286

DSCF2120.JPG220 KB · Views: 286 -

DSCF2111.JPG250 KB · Views: 287

DSCF2111.JPG250 KB · Views: 287 -

DSCF2113.JPG272.4 KB · Views: 278

DSCF2113.JPG272.4 KB · Views: 278 -

DSCF2115.JPG344.5 KB · Views: 148

DSCF2115.JPG344.5 KB · Views: 148 -

DSCF2117.JPG226.1 KB · Views: 132

DSCF2117.JPG226.1 KB · Views: 132 -

DSCF2121.JPG277 KB · Views: 99

DSCF2121.JPG277 KB · Views: 99 -

DSCF2125.JPG358.9 KB · Views: 161

DSCF2125.JPG358.9 KB · Views: 161

Last edited:

Pass DIY Addict

Joined 2000

Paid Member

Cool construction! What are you using for a pick up arm and to drive a platter?

Looks like you have some nice fabrication equipment. If I had access to tools like that, my wife wouldn't let me bring things into the house ;-)

Looks like you have some nice fabrication equipment. If I had access to tools like that, my wife wouldn't let me bring things into the house ;-)

The platter and drive mechanism was salvaged from an old idler-drive BSR turntable; Lots of torque,78 rpm,and fairly easy to adapt. And it was a better environmental choice/solution than dumping it in the garbage.

The arm assembly/vacuum routing was constructed from brass tubing sourced from a local hobby store. Shined it up,then clear-coated it to prevent corrosion.

The drive for the arm-wand was an absolute nightmare,at least from a parts standpoint. I had found an American hobby supplier for the motor,shafts, drive gears,bearings,mounting brackets etc.

I was very excited,as this would be a real time and effort saver: great prices,one-stop shopping! Right up till the part where they wanted to charge me $50USD for shipping a $100USD order to Canada. NOT!

In the end,I managed to source everything I needed from the industrial supplier I use at work.

I'll try to find the pictures of the rest of the build and post them.

The arm assembly/vacuum routing was constructed from brass tubing sourced from a local hobby store. Shined it up,then clear-coated it to prevent corrosion.

The drive for the arm-wand was an absolute nightmare,at least from a parts standpoint. I had found an American hobby supplier for the motor,shafts, drive gears,bearings,mounting brackets etc.

I was very excited,as this would be a real time and effort saver: great prices,one-stop shopping! Right up till the part where they wanted to charge me $50USD for shipping a $100USD order to Canada. NOT!

In the end,I managed to source everything I needed from the industrial supplier I use at work.

I'll try to find the pictures of the rest of the build and post them.

Pass DIY Addict

Joined 2000

Paid Member

I've been checking out the local used shops and flea markets looking for an old turn table to salvage parts from for the rest of my project. I've already been thinking about the trick that will be necessary for the arm movement - sounds like an interesting project. You don't happen to have a parts list laying around from your earlier work, do you??

- Status

- Not open for further replies.