All:

I've just obtained a vintage Rotel RA-310 integrated amplifier which I would like to use as a test-bed to learn to recondition vintage solid-state amps. My previous experiences are as a hobbyist with tube-type gear.

I see that the Rotel has capacitor output coupling, and according to the schematic, the output caps are 1000uF 35V.

I have read that one can obtain better bass response by increasing the capacitor value, so long as the voltage rating is the same or higher.

With that in mind, I was hoping to spec a pair of output capacitors at around 2000uF, 35 volts or higher.

I see there are a lot of choices out there in electrolytic caps. Some are quite expensive, many are much less so.

So my questions are these. First, am I correct to want to go to a higher capacitance? Second, what should I look for with regard to the type of electrolytic capacitors I choose? Other than physically fitting in the cabinet and price, are there any other considerations to keep in mind? I don't want to spend more than I have to, but I also don't want to do something stupid and blow the thing up.

This Rotal is not high-end and never will be - I'm just using it as a test bed for developing my own skills here.

Thanks!

I've just obtained a vintage Rotel RA-310 integrated amplifier which I would like to use as a test-bed to learn to recondition vintage solid-state amps. My previous experiences are as a hobbyist with tube-type gear.

I see that the Rotel has capacitor output coupling, and according to the schematic, the output caps are 1000uF 35V.

I have read that one can obtain better bass response by increasing the capacitor value, so long as the voltage rating is the same or higher.

With that in mind, I was hoping to spec a pair of output capacitors at around 2000uF, 35 volts or higher.

I see there are a lot of choices out there in electrolytic caps. Some are quite expensive, many are much less so.

So my questions are these. First, am I correct to want to go to a higher capacitance? Second, what should I look for with regard to the type of electrolytic capacitors I choose? Other than physically fitting in the cabinet and price, are there any other considerations to keep in mind? I don't want to spend more than I have to, but I also don't want to do something stupid and blow the thing up.

This Rotal is not high-end and never will be - I'm just using it as a test bed for developing my own skills here.

Thanks!

This is one of a series of small, early quasi-complementary designs by Rotel. My suggestion is not to go fancy with Audiophile parts as these are not audiophile amps, as you realise - just modest little stereo amplifiers that were reliable and most were trouble-free.

You don't need particularly high grade caps for the output caps. Today's caps are all better than those of 40 years ago and any reputable branded electrolytic from Panasonic, United Chemicon, Nichicon, Elna, Cornell Dubilier, Rubycon, Samhwa etc will do fine. I suggest a little more than 2,000 uF though. 3,300 - 4,700uF would deliver a more worthwhile impression of bass, provided you don't try to run the amplifier a high volume and stress the power supply. Speaking of which, don't forget to replace the power supply electrolytics and other smaller ones too in an amplifier of this age.

You may be surprised at how much smaller the new parts of the same values will be. If in doubt, you can usually uprate most capacitance values in amplifiers by 50-100% without detriment if you can't find identical values. The manufacturing tolerance on electrolytic capacitance values is quite wide so accuracy is more like a ballpark figure and dosn't need to be precise at all since it will be changing slowly over its lifetime anyway.

You don't need particularly high grade caps for the output caps. Today's caps are all better than those of 40 years ago and any reputable branded electrolytic from Panasonic, United Chemicon, Nichicon, Elna, Cornell Dubilier, Rubycon, Samhwa etc will do fine. I suggest a little more than 2,000 uF though. 3,300 - 4,700uF would deliver a more worthwhile impression of bass, provided you don't try to run the amplifier a high volume and stress the power supply. Speaking of which, don't forget to replace the power supply electrolytics and other smaller ones too in an amplifier of this age.

You may be surprised at how much smaller the new parts of the same values will be. If in doubt, you can usually uprate most capacitance values in amplifiers by 50-100% without detriment if you can't find identical values. The manufacturing tolerance on electrolytic capacitance values is quite wide so accuracy is more like a ballpark figure and dosn't need to be precise at all since it will be changing slowly over its lifetime anyway.

Thanks very much, Ian! Exactly the information I was seeking. I am planning to recap/recondition the entire amp, including the power supply cap/s and any suspect components; just for the experience to be honest. Thought I'd have a go at something like this before embarking on anything more complex and/or valuable. I really do appreciate your time, thank you again.

First, am I correct to want to go to a higher capacitance? Second, what should I look for

with regard to the type of electrolytic capacitors I choose?

I'd go with 2200uF, 50V if you can. You may have problems getting a current replacement capacitor

with the same lead type and spacing. Snap-in types also require larger mounting holes than leaded types.

It might be best to replace only a few parts at a time and then do testing, until you have enough experience.

Use quality parts from a known supplier, not off ebay.

Last edited:

I'd go with 2200uF, 50V if you can. You may have problems getting a current replacement capacitor

with the same lead type and spacing. Snap-in types require larger holes than leaded types.

It might be best to replace only a few parts at a time and then do testing, until you have enough experience.

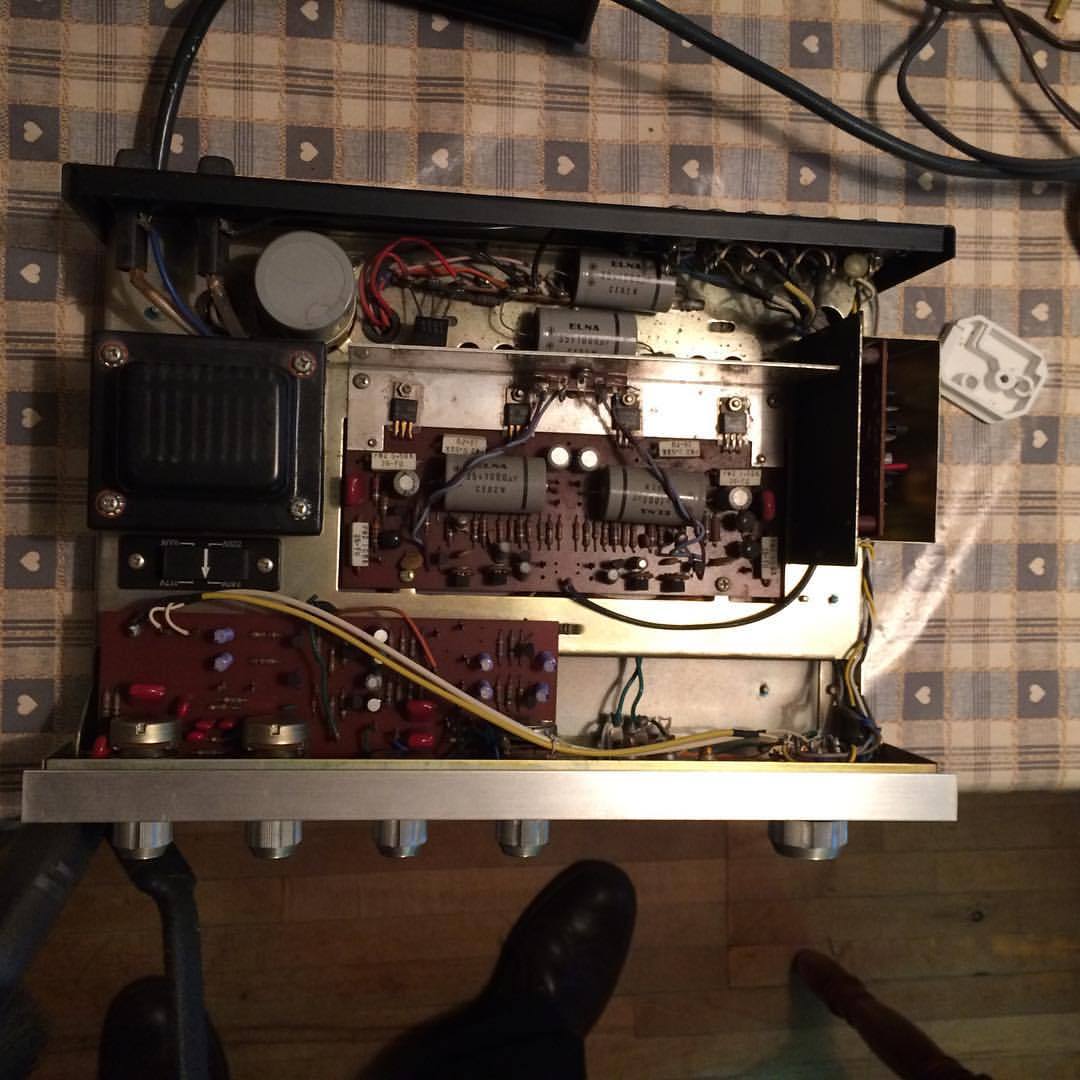

I am hoping that these will be fairly easy to replace. This is not my unit, but it is a photo someone put on the web of the same model. You can see the output caps just sort of laying there.

I think 50V for safety is an excellent idea, thank you!

FYI, the service manual with schematic for this unit is available on Hi Fi Engine:

Rotel RA-310 - Manual - Solid State Stereo Integrated Amplifier - HiFi Engine

I note that the power supply multi cap is 2200/1000/1000 35V.

Rotel RA-310 - Manual - Solid State Stereo Integrated Amplifier - HiFi Engine

I note that the power supply multi cap is 2200/1000/1000 35V.

You can see the output caps just sort of laying there. I think 50V for safety is an excellent idea, thank you!

The 50V types will last longer, too. Axial leaded parts like those may be more difficult to find.

You could instead use the more common radial (pcb mount) type and add flying leads.

In any event the replacements will likely be smaller, even a 2200uF/50V.

I note that the power supply multi cap is 2200/1000/1000 35V.

If it's a three-in-one can, you'll have to replace it with three caps, bundled together.

The 50V types will last longer, too. Axial leaded parts like those may be more difficult to find.

You could instead use the more common radial (pcb mount) type and add flying leads.

In any event the replacements will likely be smaller, even a 2200uF/50V.

Makes sense. And yes, I'll ensure I buy my parts from one of the reputable dealers (I have purchased quite a bit from Mouser, Allied, Newark, etc for my vacuum tube stuff). I just watch for sales and buy in bulk when the prices are good.

I do plan to take it one step at a time. Totally agree - a newbie like myself should replace one bit at a time, listen, make notes, and move on. That way if I do something wrong, so long as I don't blow anything up, I can back the change out easily enough. As an IT guy, I'm all about process and documentation.

If it's a three-in-one can, you'll have to replace it with three caps, bundled together.

Yes, I'm used to that with tube amps. I am not generally the kind of guy who feels the need to restuff the multi-cap canisters. I just cut the leads and solder in the new individual caps beneath the chassis, leaving the old unit disconnected but in place, unless I need the room for some reason.

With radial lead caps not supported at both ends like axial, I'd glue the new caps down to prevent flopping. I use duco cement (rubber) or 3M weatherstrip adhesive.

You may find more selection in "snap in" caps which are sorted as a different category than leaded caps by newark & mouser. These have very short leads, which you can still bend over into hooks. I like to buy the long life grade, <3000 hours service life, so I don't have to replace these parts again in my lifetime. If using snap in, a little 4 hole insulator board on the lead end of the cap will strain relieve the wires and keep them from flying around if they come unsoldered. 2 holes for the leads, 2 holes for the wires to loop through.

I find adequate bass from 3300 uf output cap selected by dynaco for their ST120. If you buy long life grade caps they will be low ESR also. This is on 8 ohm speakers, 101 db@1W1m sensitivity. If you have 4 ohm speakers or lower loudness you might like 4700 uf output caps better.

New lower ESR power supply caps may increase primary current surge at turnon. The diodes might blow. I've started using NTCR GE CL-70 or appropriate number in series with the transformer primaries. I mount them on cinch solder terminal strips.

I prefer panasonic long life snap in caps, which are assembled in USA. Nichicon has some extreme life caps I've used. Double plus to the nichicon caps in a motor drive I took out of an oven burner compartment, 5 years or more life at ~150 deg F. I've also used multicomp and united chemicon, their life test is not as strenuous as the first two. Rubicon has the tougher life test spec but doesn't seem to sell caps 1000 uf up.

Newark & digikey have the cap service life visible in the selector grid, mouser you have to download the datasheets and read them. Alliedelec I haven't ordered from since 1970. Where are they shipping from now? Used to be Chicagoland. Newark is in SC so I use them a lot, sometimes 1 day delivery for surface UPS rates. Mouser is in TX one or two more days away from me by UPS surface. Digikey is in MN also about 3 days away minimum surface. USPS priority is always about 4 days wherever it comes from.

You may find more selection in "snap in" caps which are sorted as a different category than leaded caps by newark & mouser. These have very short leads, which you can still bend over into hooks. I like to buy the long life grade, <3000 hours service life, so I don't have to replace these parts again in my lifetime. If using snap in, a little 4 hole insulator board on the lead end of the cap will strain relieve the wires and keep them from flying around if they come unsoldered. 2 holes for the leads, 2 holes for the wires to loop through.

I find adequate bass from 3300 uf output cap selected by dynaco for their ST120. If you buy long life grade caps they will be low ESR also. This is on 8 ohm speakers, 101 db@1W1m sensitivity. If you have 4 ohm speakers or lower loudness you might like 4700 uf output caps better.

New lower ESR power supply caps may increase primary current surge at turnon. The diodes might blow. I've started using NTCR GE CL-70 or appropriate number in series with the transformer primaries. I mount them on cinch solder terminal strips.

I prefer panasonic long life snap in caps, which are assembled in USA. Nichicon has some extreme life caps I've used. Double plus to the nichicon caps in a motor drive I took out of an oven burner compartment, 5 years or more life at ~150 deg F. I've also used multicomp and united chemicon, their life test is not as strenuous as the first two. Rubicon has the tougher life test spec but doesn't seem to sell caps 1000 uf up.

Newark & digikey have the cap service life visible in the selector grid, mouser you have to download the datasheets and read them. Alliedelec I haven't ordered from since 1970. Where are they shipping from now? Used to be Chicagoland. Newark is in SC so I use them a lot, sometimes 1 day delivery for surface UPS rates. Mouser is in TX one or two more days away from me by UPS surface. Digikey is in MN also about 3 days away minimum surface. USPS priority is always about 4 days wherever it comes from.

Last edited:

With radial lead caps not supported at both ends like axial, I'd glue the new caps down to prevent flopping. I use duco cement (rubber) or 3M weatherstrip adhesive.

You may find more selection in "snap in" caps which are sorted as a different category than leaded caps by newark & mouser. These have very short leads, which you can still bend over into hooks. I like to buy the long life grade, <3000 hours service life, so I don't have to replace these parts again in my lifetime. If using snap in, a little 4 hole insulator board on the lead end of the cap will strain relieve the wires and keep them from flying around if they come unsoldered. 2 holes for the leads, 2 holes for the wires to loop through.

I find adequate bass from 3300 uf output cap selected by dynaco for their ST120. If you buy long life grade caps they will be low ESR also.

New lower ESR power supply caps may increase primary current surge at turnon. The diodes might blow. I've started using NTCR GE CL-70 or appropriate number in series with the transformer primaries. I mount them on cinch solder terminal strips.

I was wondering about the ESR and whether or not that would significantly matter. Those current inrush limiters are interesting; a shame they cost so much per unit, eh? Where would you put them in the schematic? You mean in front of the power transformer or just after and before the rectifying diodes?

I like the idea of using a little bit of insulator board to mount the caps. I happen to have such things laying around.

I put NTCR surge limiters after the AC fuse and switch and before the transformer AC wire. The CL-70 is about 4 amps continuous, that should cover a 50-75 W/ch stereo amp. GE NTCR's last time I bought were made in USA - you know the country that loads the medical care costs on all the manufacturing jobs? I pay extra to support those of my neighbors not on welfare when I can. You can salvage NTCR from dead VFD motor drives like Siemens, AllenBradley, TBwoods, Yakasaka, and also PCAT ATX power supplies. The Chinese ones are green, round, and have the hot current rating (I think) printed on them.

Yeah, I learned about the insulator board strain relief on snap in caps from a diyaudio poster. My ST120 got hot enough to melt solder during a 3.5 hour Christmas cantata rehearsal (I'm a keyboard player) the output cap feed wire sprung up, hit the perforated steel cover, and the blue fireball was about 15" in diameter. Toasted the driver resistors, only the leads left. The junior choir members were very impressed.

Yeah, I learned about the insulator board strain relief on snap in caps from a diyaudio poster. My ST120 got hot enough to melt solder during a 3.5 hour Christmas cantata rehearsal (I'm a keyboard player) the output cap feed wire sprung up, hit the perforated steel cover, and the blue fireball was about 15" in diameter. Toasted the driver resistors, only the leads left. The junior choir members were very impressed.

Last edited:

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Solid State

- Question on Replacing Output Caps on Amplifier