Hi:

Anyone old enough to remember the Wireless World June 1979 design "Bookshelf Loudspeaker MKII" by Jim Wilkinson.

I built one back in the early 80's and still use it today. Just curious as to how good or bad it was.

It used an Audax HD13D34H tweeter and a KEF B200 ( I blew mine, so I now have B200G)

My cross over is hand wound aircore with heavy wire( some ~14 ga)

Peter

Anyone old enough to remember the Wireless World June 1979 design "Bookshelf Loudspeaker MKII" by Jim Wilkinson.

I built one back in the early 80's and still use it today. Just curious as to how good or bad it was.

It used an Audax HD13D34H tweeter and a KEF B200 ( I blew mine, so I now have B200G)

My cross over is hand wound aircore with heavy wire( some ~14 ga)

Peter

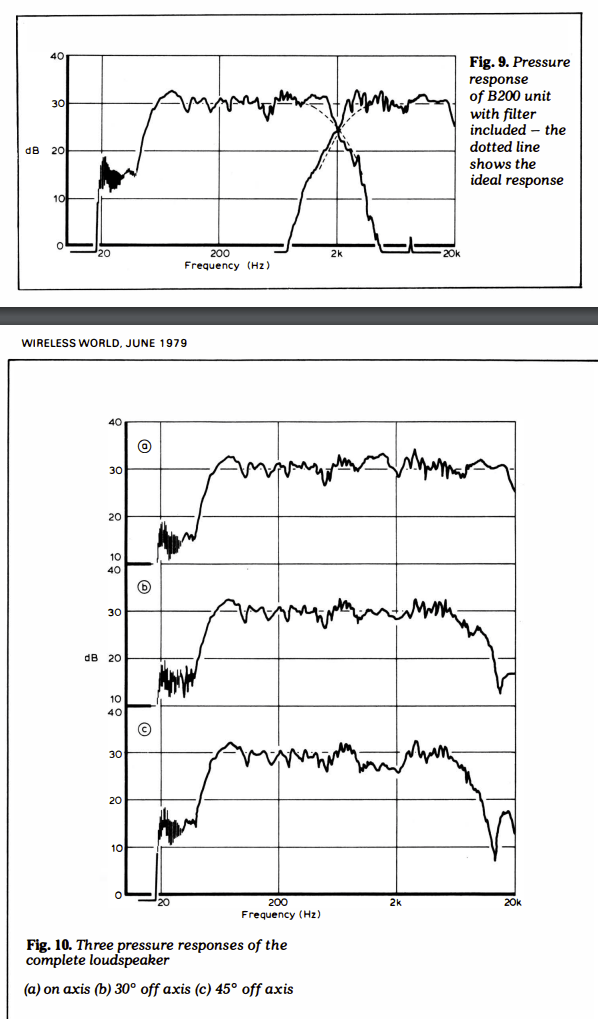

That is one complicated crossover! The B200 suspension tend to stiffen over the years but a closed box is less sensitive to such things than a tuned construction. The capacitors may have degraded if they are electrolytic and the bitumen damping may have dried out and have become brittle. If electrolytic replace the ones on the tweeter parts first. If that brings an improvement go for the others as well

That for sure is one crossover. The whole design is well-thought out. And better documented than the average modern design. I think it really is a bookshelf design, though the measurement conditions aren’t clear.

The main issue is: how did the drivers age. Some old D34s lying around here still perform OK, but that is no guarantee. And next to that, the SP1075 isn’t a SP1014. One last issue could be the electrolytes in the crossover, they probably have drifted due to their ageing.

The main issue is: how did the drivers age. Some old D34s lying around here still perform OK, but that is no guarantee. And next to that, the SP1075 isn’t a SP1014. One last issue could be the electrolytes in the crossover, they probably have drifted due to their ageing.

Last edited by a moderator:

I haven't opened it up, but I think I had used mostly film caps where possible. I didn't check about my pavement sealer I used to line the cabinets.

I initially had B200's but it was the 80's and I listened to loud music and I cooked/deformed the voice coils. I sent them to the UK to KEF for repair and they repaired them by sending me B200Gs. B200 was out of production by the late 80's ? if i remember correctly.

They still sounded good enough that I didnt' pay any more attention.

I used a heavy wire mesh paper tray for my speaker grill.

P

PS: it took me about a month, at lunch time at work to wind all the coils and to parallel all the film caps up to the correct values!

I initially had B200's but it was the 80's and I listened to loud music and I cooked/deformed the voice coils. I sent them to the UK to KEF for repair and they repaired them by sending me B200Gs. B200 was out of production by the late 80's ? if i remember correctly.

They still sounded good enough that I didnt' pay any more attention.

I used a heavy wire mesh paper tray for my speaker grill.

P

PS: it took me about a month, at lunch time at work to wind all the coils and to parallel all the film caps up to the correct values!

Last edited by a moderator:

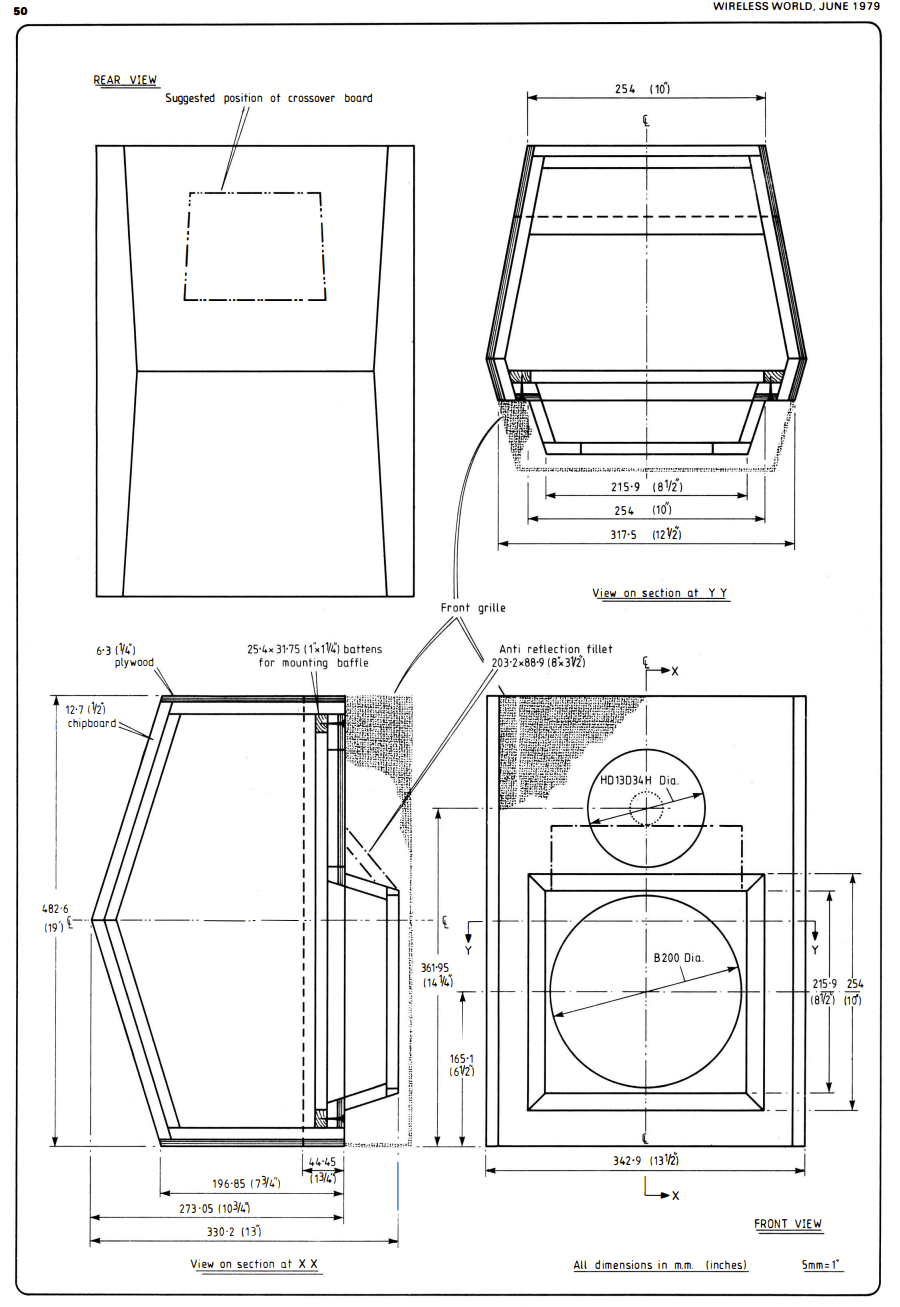

Not something I would build today - very complex crossover, labor-intensive cabinet, modest off-axis behaviour - but as object in itself, a loudpeaker on par with a lot of good non-waveguided 2 way bookshelves. B200 surround should benefit from plasticizer treatment, like DBP.

Hypotehtically, 3D-printed or CNC'd baffle can really bring this design up to today's standards.

Hypotehtically, 3D-printed or CNC'd baffle can really bring this design up to today's standards.

I took the front facisa plate off of the tweeter so I could mount the tweeter as close as possible to the B200/B200G. My cabinet has almost the same volume but is a simple rectangular box. The wood working required was beyond what I could do with hand tools so I took the easy route.

What is DBP ?

My B200G's surround looks new. Its been in my garage near the ceiling and never gets sunlight. May be I need to look again, but its probably dusty!

I guess I should take a picture of it, so you guys can have a laugh.

P

What is DBP ?

My B200G's surround looks new. Its been in my garage near the ceiling and never gets sunlight. May be I need to look again, but its probably dusty!

I guess I should take a picture of it, so you guys can have a laugh.

P

Dibuthyl phtalate, commonly used to increase plasticity of a wide range of polymers.

Kind of hard to take a picture since they are up on a shelf next to the ceiling.

The fascia of the tweeter was removed so I could mount it close to the B200G, and also leave a space for a panel brace between the two drivers on the back side.

The fascia of the tweeter was removed so I could mount it close to the B200G, and also leave a space for a panel brace between the two drivers on the back side.

Attachments

- Home

- Loudspeakers

- Multi-Way

- question about an old speaker design, was it good ?

![DSC_3133[1].JPG](/community/data/attachments/1070/1070315-cd303bbc859827caba9c8241e7b88c4a.jpg)

![DSC_3134[1].JPG](/community/data/attachments/1070/1070316-8ac6fc1938535dc2f530fdc4e93f4bbe.jpg)