Hi All!

My late 44 (s/n 034981) is hooked up through a 405.2 to a pair of cheap 4 Ohm speakers and I am having difficulty replicating the occasional sharp crack that I was getting more regularly through my Spendor LS3/5a speakers.

The 44 was last serviced by Quad in 1995. I carried out the 'Erratic input switching' mod and mistakenly used a 47uf cap instead of a 4.7uf cap. Later after use it stopped completely, and it is now working again after replacing the relay and blown zeners 404/5 and the 47uf switching mod cap.

I have been using the 405.2 regularly with a 33 and have had no trouble with it.

2 hours and not a crack in sight. Does any one have any idea what it may be. I want to sell them but don't have the confidence while I have this issue.

Many thanks

Enthusiastic and an amatuer

My late 44 (s/n 034981) is hooked up through a 405.2 to a pair of cheap 4 Ohm speakers and I am having difficulty replicating the occasional sharp crack that I was getting more regularly through my Spendor LS3/5a speakers.

The 44 was last serviced by Quad in 1995. I carried out the 'Erratic input switching' mod and mistakenly used a 47uf cap instead of a 4.7uf cap. Later after use it stopped completely, and it is now working again after replacing the relay and blown zeners 404/5 and the 47uf switching mod cap.

I have been using the 405.2 regularly with a 33 and have had no trouble with it.

2 hours and not a crack in sight. Does any one have any idea what it may be. I want to sell them but don't have the confidence while I have this issue.

Many thanks

Enthusiastic and an amatuer

If you want to enter the diy repair hobby, you'll need to take the cover off and install a detector to prove where the fault is. Such detector can be an oscilloscope, or more economically an analog voltmeter on AC scale protected by a .047 200v cap in the negative lead to speaker ground. You haven't yet decided if the fault is in both speakers, or just one. If in both, you check the power supply common to both channels. If just one, you first set up a trap halfway through the circuit to determine whether the fault is before or after that point. Once data is taken, then the suspect half of the circuit is halved again by another test point to quarter the list of suspects. So on until actual component is found. DVM are less useful because they average readings over 2 to 4 seconds and minimize sudden shifts in operating point. Heat gun (hair dryer) or circuit cool spray may speed up the process of detection.

As this is time consuming, if you are not enthusiastic about learning something, I would sell it off. Finding the problem could take considerable time. Ebay allows amps to be sold "for parts or repair", at least in the US. Pictures with the cover off at least show viewers you haven't harvested the heat sinks & transformer out of it. If you don't want the risk of a return, you may sell it for cash on craigslist (North America) or gumtree (UK). As Europe requires payment for recyling used appliances, the market for such transactions there may be thin or illegal.

As this is time consuming, if you are not enthusiastic about learning something, I would sell it off. Finding the problem could take considerable time. Ebay allows amps to be sold "for parts or repair", at least in the US. Pictures with the cover off at least show viewers you haven't harvested the heat sinks & transformer out of it. If you don't want the risk of a return, you may sell it for cash on craigslist (North America) or gumtree (UK). As Europe requires payment for recyling used appliances, the market for such transactions there may be thin or illegal.

Many thanks indianajo, it is both speakers and could be the power supply. I would be happy to work through lifting and testing individual components. Is there an order of testing for a fault like this?

There are a lot of contacts that can get tarnished and the connectors and leads would be the first thing I would check along with;

Does the volume control have any effect ... if it doesn't, it is likely after any pre amp stages. Is the issue on one channel or both ... swop the 44 to amplifier leads over to check.

Etc.

Keep logical and you will find the source.

Does the volume control have any effect ... if it doesn't, it is likely after any pre amp stages. Is the issue on one channel or both ... swop the 44 to amplifier leads over to check.

Etc.

Keep logical and you will find the source.

As Mr Snell said, contacts can oxidize and interrupt low level signals. Removing & replacing can clean the oxide off. Some types connectors are age prone, like ones with press in wires between two forks. The telephone company invented these, and at the 48 v 100 ma the bell phone used they were not a problem. 15 v & 10 ma, yes they are. Edge board connectors were a problem, mostly abandoned by designers by 1972.

Pots and switches have contacts. These sometimes can be sprayed out with cleaner if open or ittermittant, or must be replaced if sealed. Warning most contact cleaners are flammable: no smoking, open flames, electricity turned on or off within 10 m. The cleaners that aren't flammable can dissolve cheap plastics. Test before use.

If pop is in the power supply, monitoring the various voltages out with the AC VOM for sudden shifts at the same time as the pop will point out which one. You'll need a schematic or layout to assist this, although the experienced can spot the points usually without. High failure parts after some years are electrolytic caps. aluminum bottles filled with aluminum foil & slime, sealed with rubber or something better. Old ones the rubber cracks and they gas out the water and become ittermittant or merely high ESR (resistance).

Of course pops can always be bad solder joints, another sort of contact that responds to temperature or age. Not all bad joints look bad. I've found a few good looking joints that popped when pressed in factory built products. I use a meter probe or wood stick to probe around.

Warning to newbies, use only one hand at a time. Voltage over 24 from one hand to the other can stop your heart. Use a clip lead on the negative meter probe. No jewelry on hands wrists or neck. 1 v @ 25 A through a ring can burn your flesh to charcoal. Don't touch metal until you measure it is <1 v to ground. Wear safety glasses especially desoldering. Solder splashes and parts explode sometimes. Don't work alone or distracted by entertainment. Don't probe the mains entry area until very experienced. Don't repair switcher supplies until very experienced, they have many components are high voltage and others store lots of energy. Don't repair amps >100 w/ch until experienced.

Pots and switches have contacts. These sometimes can be sprayed out with cleaner if open or ittermittant, or must be replaced if sealed. Warning most contact cleaners are flammable: no smoking, open flames, electricity turned on or off within 10 m. The cleaners that aren't flammable can dissolve cheap plastics. Test before use.

If pop is in the power supply, monitoring the various voltages out with the AC VOM for sudden shifts at the same time as the pop will point out which one. You'll need a schematic or layout to assist this, although the experienced can spot the points usually without. High failure parts after some years are electrolytic caps. aluminum bottles filled with aluminum foil & slime, sealed with rubber or something better. Old ones the rubber cracks and they gas out the water and become ittermittant or merely high ESR (resistance).

Of course pops can always be bad solder joints, another sort of contact that responds to temperature or age. Not all bad joints look bad. I've found a few good looking joints that popped when pressed in factory built products. I use a meter probe or wood stick to probe around.

Warning to newbies, use only one hand at a time. Voltage over 24 from one hand to the other can stop your heart. Use a clip lead on the negative meter probe. No jewelry on hands wrists or neck. 1 v @ 25 A through a ring can burn your flesh to charcoal. Don't touch metal until you measure it is <1 v to ground. Wear safety glasses especially desoldering. Solder splashes and parts explode sometimes. Don't work alone or distracted by entertainment. Don't probe the mains entry area until very experienced. Don't repair switcher supplies until very experienced, they have many components are high voltage and others store lots of energy. Don't repair amps >100 w/ch until experienced.

Strongly urge that you no longer allow the noise to be through your LS3/5As or they could be damaged.

Even if you don't think it's that loud. Use any junk speakers instead. Then you can poke around with

an insulated tool (stick, pencil, etc.) to see if you can trigger the noise.

Otherwise, at least add a series resistor for each speaker to reduce the danger, something like 1k at 1W.

You don't want to have to replace the tweeters.

Also consider the possibility that the noise is caused by an appliance in the building, not your stereo.

Even if you don't think it's that loud. Use any junk speakers instead. Then you can poke around with

an insulated tool (stick, pencil, etc.) to see if you can trigger the noise.

Otherwise, at least add a series resistor for each speaker to reduce the danger, something like 1k at 1W.

You don't want to have to replace the tweeters.

Also consider the possibility that the noise is caused by an appliance in the building, not your stereo.

Last edited:

If possible use a 1:1 isolation transformer to give yourself some protection from electrocution, or at least make sure you have a residual current detector breaker in the mains supply. Use a 'dim bulb' current limiter in the electricity lead for the 44 with a small incandescent bulb, say 10 or 15W. Use a CRO on the output of the 44, or connect the 405 with some old car speakers or something else you are not going to miss. Then with the lid off gently prod suspect components with a non-conductive chopstick. Crackling can be caused by 'dry' or broken solder joints or semiconductors that are failing. The latter are usually detectable by cooling one at a time with a drop of freezer spray. Flexing the circuit board with pressure may reveal cracked printed tracks which could also be the culprit.

Thank you johnmath. We are on a RCD here though I think I will make up a 'dim bulb' limiter. I have just bought some old 4 Ohm 70w speakers off ebay that I am using. Not sure what CRO means but will give your and others advice a go tomorrow.

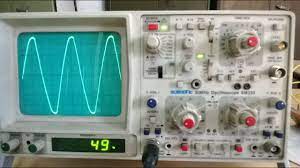

A CRO is a cathode ray oscilloscope, sort of a TV for looking at waveforms. Nowadays they are usually LED or USB / PC based. You would connect this to the output of your preamp and look for disturbances when you are prodding around inside.

Isolation transformers are essential for repairing obsolete CRT televisions, with the flyback transformer coupled directly to the mains and the horizontal sweep similarly high powered. As 100 w/ch amplifiers rarely have trouble from the fuse to the primary side of the transformer, I find it safe enough to not touch the mains AC area. Yes a dim bulb supply in series with the AC plug can prevent an amp from blowing the fuse over & over when shorts occur. That doesn't seem to be the problem here. I use 100 W incandescent bulb for 30 to 100 w/ch amps.If possible use a 1:1 isolation transformer to give yourself some protection from electrocution, or at least make sure you have a residual current detector breaker in the mains supply.

I find 30 year old scopes so full of dozens of expired electrolytic caps as to be not worth the trouble of fixing. I have owned three, used zero. My Simpson 266XLPM analog meter is 26 years old, has no electrolytic caps, and works fine for tracing either pops or music through an amp.

- Home

- Amplifiers

- Solid State

- Quad 44 occasional sharp crack!