Member

Joined 2009

Paid Member

I'm trying to link the magnets through the box in my push-pull, but its clearly way easier to do this with your push-push (magnets back to back) where the box need not handle the forces between magnets at all. In the push-pull the forces have to go through the box but with zero experience in this game I'm not sure my box design is adequate but I am trying to couple them to the box as you suggest. I've posted the design in a separate thread to try and get some input on that. Unfortunately a common rod doesn't look feasible in my case.

Maybe somebody (e.g. CSS) should make an integrated dual-driver solution optimized for a push-push

Maybe somebody (e.g. CSS) should make an integrated dual-driver solution optimized for a push-push

Member

Joined 2009

Paid Member

tinitus said:Small problem is that you need access to the drivers inside the box, after they are mounted

with threaded rod you can work it through from the front - just put it in the jaws of a power drill

Bigun said:

with threaded rod you can work it through from the front - just put it in the jaws of a power drill

You dont need the baffle to baffle rod...just use some wood bracing

I was talking about the adjustment of the pressure between the magnet poleplates 😉

Member

Joined 2009

Paid Member

I think we deserve a dedicated dual-cone driver. We have only one magnet shared between them with two voice coils. There is one common frame.

Choose a driver with a stable frame, skip the magnet-magnet rod/connection. Use rods between the drivers mounting holes instead. There is after all a limited force the coil can push/pull and flex the frame.

Member

Joined 2009

Paid Member

1. I'm confused. I thought the push-pull concept was introduced only to cancel asymmetries of "in" vs "out" movement? But some posts above make it sound like they are wired the opposite way. There should no creeping around of a push-pull pair box unless they were wired up that strange way.

2. I've built 16 driver series-parallel push-pull woofers. Very solidly built into what had once been a house door entry with foundation and masonry around it. Very satisfactory but a divorce separated me from this speaker... she kept the house. Hard for me to conceive how you'd wire just two speakers except with two amps, not that I'm excessively fussy about damping.

3. Seems unsound to me to use the back-end of drivers as structural elements even though very sound to use cross-bracing otherwise. Virtually no way to keep from having destructive box/mechanical forces acting on the magnetic structures when hooked up as some have suggested above.

4. Spooky to have a woofing pair separated too much, like on opposite sides of a box unless the cross-over is low and steep.

2. I've built 16 driver series-parallel push-pull woofers. Very solidly built into what had once been a house door entry with foundation and masonry around it. Very satisfactory but a divorce separated me from this speaker... she kept the house. Hard for me to conceive how you'd wire just two speakers except with two amps, not that I'm excessively fussy about damping.

3. Seems unsound to me to use the back-end of drivers as structural elements even though very sound to use cross-bracing otherwise. Virtually no way to keep from having destructive box/mechanical forces acting on the magnetic structures when hooked up as some have suggested above.

4. Spooky to have a woofing pair separated too much, like on opposite sides of a box unless the cross-over is low and steep.

I dont agree that push-pull only holds positive aspects

I can easily imagine negative effects as well

I would think, that to deal with eventual negative effects, each woofer should have its own seperate chamber

Still, most important factors must be driver quality, meaning proper linear behaviour, proper box alignment, and room interaction...without those covered any form of bracing etc means nothing

But if everything of that is properly covered, then much else probably wont matter much anyway

Kind of like pouring water into a diesel engine

It all sounds very much like "hype" to me

A VERY heavy box might be just as effective

I can easily imagine negative effects as well

I would think, that to deal with eventual negative effects, each woofer should have its own seperate chamber

Still, most important factors must be driver quality, meaning proper linear behaviour, proper box alignment, and room interaction...without those covered any form of bracing etc means nothing

But if everything of that is properly covered, then much else probably wont matter much anyway

Kind of like pouring water into a diesel engine

It all sounds very much like "hype" to me

A VERY heavy box might be just as effective

Member

Joined 2009

Paid Member

bentoronto said:I've built 16 driver series-parallel push-pull woofers. Very solidly built into what had once been a house door entry with foundation and masonry around it. Very satisfactory but a divorce separated me from this speaker...

That's a shame, I hope the speaker wasn't the cause, my wife wouldn't be too impressed if I built a sub into the door entry that's for sure.

My decision to use push-pull was mostly out of curiosity and desire to do something a little different from the crowd. But I did get a lot of useful information from others who have tried this. The first place I came across was this:

http://www.teresaudio.com/haven/subs/subs.html

and there are several others (e.g. Dave at planet10).

Member

Joined 2009

Paid Member

Well progress has been made. The side of the box housing the inverted driver is mostly finished and painted black inside. It's not the most accurate job, if I were ever to build another I'd know where to focus my effort.

I've decided no way I'm making up all those fancy braces I had planned. The accuracy needed on so many edges implies a Spring season spent sanding and cussing. I will devise something more practical.

(apologies for the poor state of my deck... but the snow has only recently receded)

I've decided no way I'm making up all those fancy braces I had planned. The accuracy needed on so many edges implies a Spring season spent sanding and cussing. I will devise something more practical.

(apologies for the poor state of my deck... but the snow has only recently receded)

Attachments

Bigun said:

I've decided no way I'm making up all those fancy braces I had planned. The accuracy needed on so many edges implies a Spring season spent sanding and cussing. I will devise something more practical.

A gentle tap to your table saw fence can get you within .010" and shims can be used against the stop on your cross cut sled to get even closer. You just visit the table saw a couple times until it fits.

Epoxy with filler (like wood flour) or formulated as a structural adhesive (System 3 T-88) makes a strong (good for things like airplane wings) gap-filling joint so you don't have to get that close or apply any clamping pressure.

Member

Joined 2009

Paid Member

I don't have a table saw. This is all getting done with a hand-held circular saw, a stanley end grain plane, a borrowed router, a portable bench and sandpaper. Right now I have only a couple of little clamps which aren't long enough to get across the side of the cube. There are two sides of the box gluing in the basement, two bags of cement on top and my tool box hanging off some string on one corner to close a gap and some rubber mats on the floor in case the string breaks.

Bigun said:I don't have a table saw. This is all getting done with a hand-held circular saw, a stanley end grain plane, a borrowed router, a portable bench and sandpaper. Right now I have only a couple of little clamps which aren't long enough to get across the side of the cube. There are two sides of the box gluing in the basement, two bags of cement on top and my tool box hanging off some string on one corner to close a gap and some rubber mats on the floor in case the string breaks.

Necessity is the mother of invention. I love it! I've done some pretty crazy things when I didn't have the correct tools. 😀

Member

Joined 2009

Paid Member

JLH said:Necessity is the mother of invention. I love it! I've done some pretty crazy things when I didn't have the correct tools. 😀

That's why in the UK they call it DIY= Destroy It Yourself

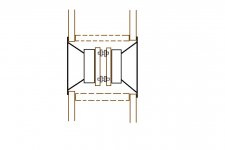

I'm simplifying the braces, there will be more of them yet but here's the box taking shape (photo is a little grainy)...

Attachments

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Subwoofers

- Push-Push or Push-Pull