Hi all!

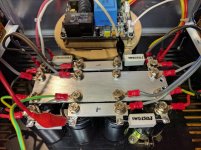

Slightly odd question. I built the below and the end result had some awful hum. The amp itself is an aleph 3 clone, drawing a bit over an amp per channel, and the caps are 15000uf.

After thinking through the situation I thought perhaps the impedance in the earthing was the issue (a wee ripple in the earth at the signal input was a hint), so I sanded back the ally plate to clear off any oxidation that might have been impeding the current flow. End result was much less hum!

With this being a clue, I'm wondering the following.

Is ally suitable in this purpose in the first place?

Will the ally oxidise over time back to where it was before anyway?

Is a piece of pcb a suitable substitute?

And come to think of it - screw on terminal caps have ally terminals... whats the go with oxidation on these?

Cheers all!

Slightly odd question. I built the below and the end result had some awful hum. The amp itself is an aleph 3 clone, drawing a bit over an amp per channel, and the caps are 15000uf.

After thinking through the situation I thought perhaps the impedance in the earthing was the issue (a wee ripple in the earth at the signal input was a hint), so I sanded back the ally plate to clear off any oxidation that might have been impeding the current flow. End result was much less hum!

With this being a clue, I'm wondering the following.

Is ally suitable in this purpose in the first place?

Will the ally oxidise over time back to where it was before anyway?

Is a piece of pcb a suitable substitute?

And come to think of it - screw on terminal caps have ally terminals... whats the go with oxidation on these?

Cheers all!

Attachments

Last edited:

Noted! 🙂 and thank you for the input JonSnell

That said, how big a star point is ok? Ie in this case a 120x35mm chunk of 3mm ally plate say for instance?

And ally has (IIRC) 60% of the conductivity of copper @ 40% of the weight making that 3mm plate of ally superior to a sheet of copper in this instance... sooo, where does that leave us?

I do indeed follow the logic of the above advice, but I fail to understand why how attaching all the GND connections to a single point instead of a large chunk of ally makes a difference. I could indeed wire them all to a single point in the middle of the plate, but... the resistivity between each of the terminals is ~0R. So I have to ask 'why'?

Forgive me if this seems like a challenge, but I would like to understand why the above advice works.

That said, how big a star point is ok? Ie in this case a 120x35mm chunk of 3mm ally plate say for instance?

And ally has (IIRC) 60% of the conductivity of copper @ 40% of the weight making that 3mm plate of ally superior to a sheet of copper in this instance... sooo, where does that leave us?

I do indeed follow the logic of the above advice, but I fail to understand why how attaching all the GND connections to a single point instead of a large chunk of ally makes a difference. I could indeed wire them all to a single point in the middle of the plate, but... the resistivity between each of the terminals is ~0R. So I have to ask 'why'?

Forgive me if this seems like a challenge, but I would like to understand why the above advice works.

Last edited:

Without a schematic of the added 0R15s and what part they play in the power supply, it is hard to comment however, it always has been common practice to have a common source for the main ground/earth point.

All, without exception, quality power amplifier power supplies that use more than a single pair of main smoothing capacitors, unless on a dedicated pcboard, use copper straps for common rails and grounding.

This avoids the effects of oxidisation between metals. As we all know, aluminium oxide is an excellent insulator.

The grounding from the loudspeakers return to the same point avoiding a current feedback issue that creates 100HZ or 120HZ hum dependent on your country.

Always return only one ground point from each part of the circuit. Eg; Input ground, Loudspeaker ground and Chassis.

Do you get mains hum or smoothing hum? There is a world of difference.

All, without exception, quality power amplifier power supplies that use more than a single pair of main smoothing capacitors, unless on a dedicated pcboard, use copper straps for common rails and grounding.

This avoids the effects of oxidisation between metals. As we all know, aluminium oxide is an excellent insulator.

The grounding from the loudspeakers return to the same point avoiding a current feedback issue that creates 100HZ or 120HZ hum dependent on your country.

Always return only one ground point from each part of the circuit. Eg; Input ground, Loudspeaker ground and Chassis.

Do you get mains hum or smoothing hum? There is a world of difference.

Remove your aluminium.

Use copper. Wire or plate.

each connection between dissimilar metals introduces risk of corrosion.

Using the SAME metal at each joint removes the electrochemical corrosion risk.

Nearly pure copper for wires and tags and traces and plates are close enough to being the SAME metal.

Changing the alloy proportions can re-introduce the corrosion.

If one uses the SAME metal, then the only normal corrosion is excluded by using a gas tight joint. This keeps water and oxygen out of the contact surfaces and the joint will remain as clean as it was when jointed.

Use copper. Wire or plate.

each connection between dissimilar metals introduces risk of corrosion.

Using the SAME metal at each joint removes the electrochemical corrosion risk.

Nearly pure copper for wires and tags and traces and plates are close enough to being the SAME metal.

Changing the alloy proportions can re-introduce the corrosion.

If one uses the SAME metal, then the only normal corrosion is excluded by using a gas tight joint. This keeps water and oxygen out of the contact surfaces and the joint will remain as clean as it was when jointed.

Last edited:

don't use "grounds". Don't take wires to random connections. Make EVERY inter module connection a two wire connection. Run the Flow and Return wires of that two wire connection as a PAIR. Do not separate that PAIR to include a loop area. Loops are aerials. They pick up and emit emi/interference.Always return only one ground point from each part of the circuit. Eg; Input ground, Loudspeaker ground and Chassis.

Make all you loop areas as small as you can manage. Coaxial and twisted are good and effective at minimising loop area.

Implementing a badly arranged star ground that separates the Flow from the Rturn will make the equipment susceptible to interference.

This article was very helpful for me to understand the grounding.

http://www.diyaudio.com/forums/diya...udio-component-grounding-interconnection.html

http://www.diyaudio.com/forums/diya...udio-component-grounding-interconnection.html

Cheers for the advice all.

@Old and cranky - noted. I intend to tidy that when I finalize the PSU...

@plasnu - thanks! That's quite the comprehensive read! I'll add it to the list.

@andrewT - noted (and mostly followed already) on the loop area note

@JonSnell - the 0R15's are part of a CRC PSU for each channel, so each rail is CRCCRC with power for each channel being taken from each 'side' and the rectifier feeding into the 'middle'. I have followed star grounding upto the ally plate, where I've terminated each feed utilising the screw terminals of the caps. I didn't necessarily see the point of drilling a specific hole to star everything onto given they're all on a 3mm chunk of ally. Hum is more or less gone now after scrubbing the ally sheet, so all good there.

Thanks for the input all. 🙂

@Old and cranky - noted. I intend to tidy that when I finalize the PSU...

@plasnu - thanks! That's quite the comprehensive read! I'll add it to the list.

@andrewT - noted (and mostly followed already) on the loop area note

@JonSnell - the 0R15's are part of a CRC PSU for each channel, so each rail is CRCCRC with power for each channel being taken from each 'side' and the rectifier feeding into the 'middle'. I have followed star grounding upto the ally plate, where I've terminated each feed utilising the screw terminals of the caps. I didn't necessarily see the point of drilling a specific hole to star everything onto given they're all on a 3mm chunk of ally. Hum is more or less gone now after scrubbing the ally sheet, so all good there.

Thanks for the input all. 🙂

- Status

- Not open for further replies.

- Home

- Amplifiers

- Pass Labs

- PSU build earthing impedance issue (ally plate) and hum